Liquid silicone overmolding and double-shot molding component surface treatment method

A secondary molding and double-shot molding technology, applied in the direction of coating, can solve problems such as uneven distribution and irregular marks, and achieve the effect of improving tension, increasing contact area, and even and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for surface treatment of parts in secondary molding of liquid silicone and two-shot molding, the steps of which are as follows: S1: use plasma technology to treat the surface of parts; S2: use a liquid coating box to apply diluted primer on the surface of parts; S3: Perform injection molding. The diluted primer is prepared from the primer and additives in a volume ratio of 1:1 to 1:10. In the diluted primer, the ratio of primer to additive is 1:8. The additive is n-hexane or toluene.

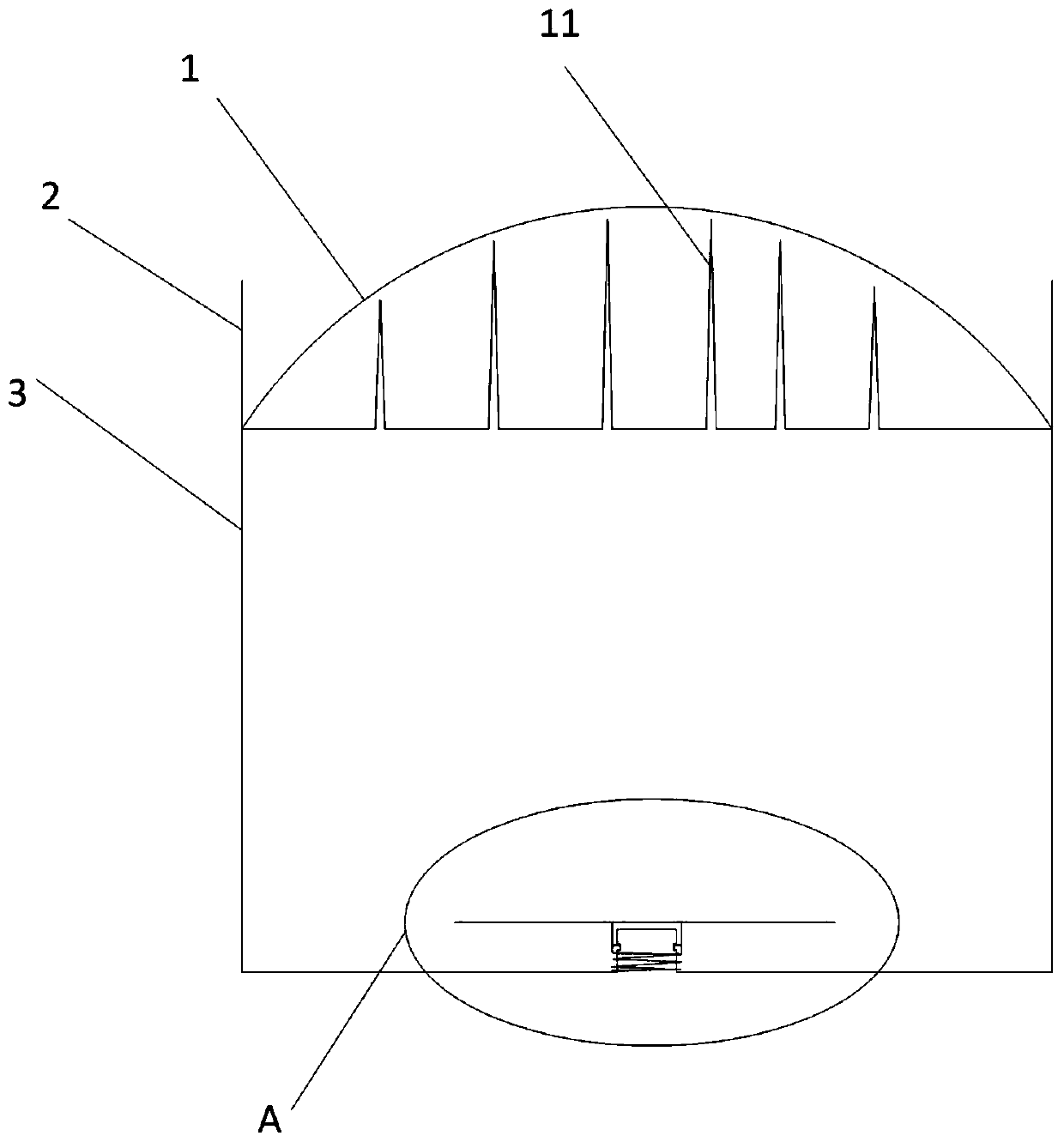

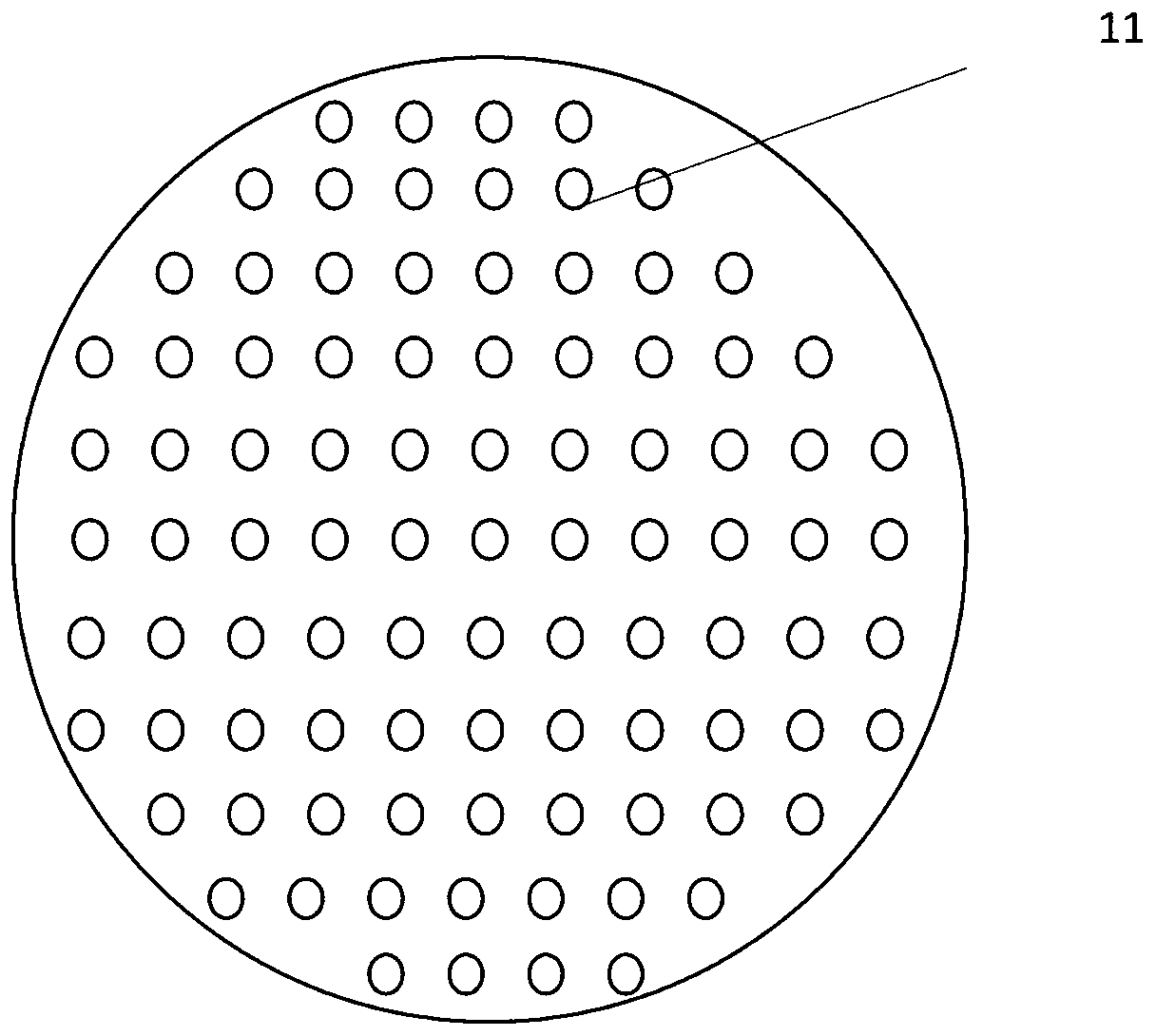

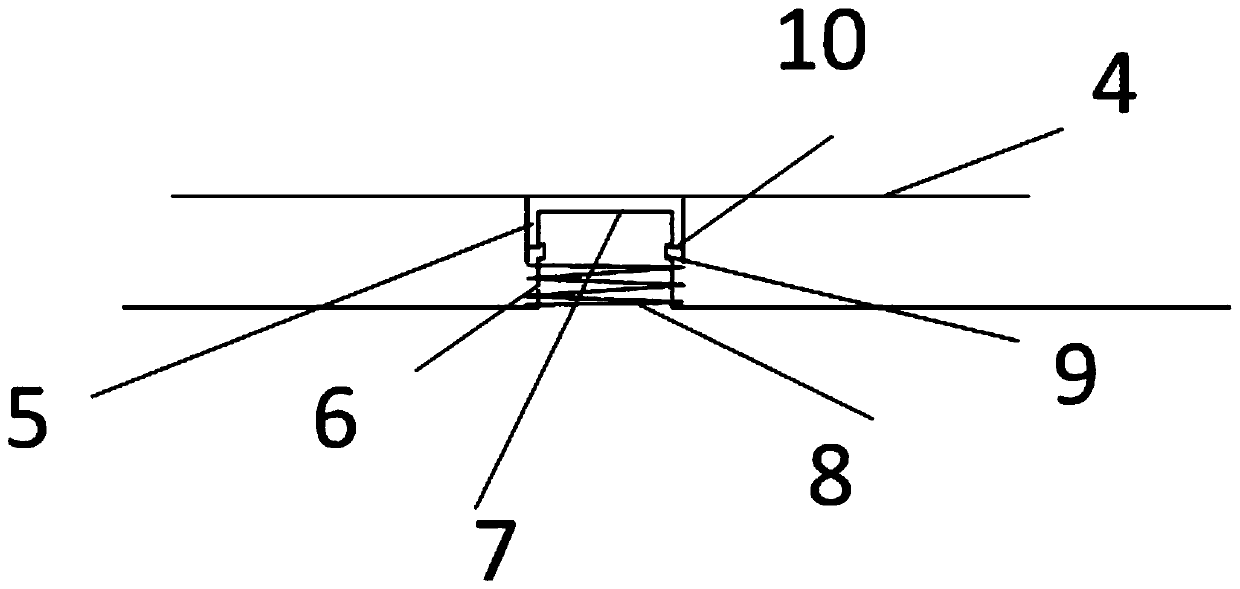

[0019] The liquid coating box described in S2 includes: a box body 3, which is a cylinder without a cover, and is used to hold a diluted primer; a spherical sponge, which is used as a top cover of the cylinder, is fixedly connected to the box body 3; The pressure limiting ring 2 is installed on the box body 3 and is fixedly connected with the box body 3, and is extended from the side of the box body 3 along the axial direction; the height of the pressure limiting ring 2 is less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com