Energy storage unit and refrigeration/insulation container

An energy storage unit and packaging technology, which is used in packaging, transportation and packaging, transportation of passenger cars, etc., can solve the problems of troublesome installation and difficult fixing of the energy storage tube, and achieve the effect of convenient installation and fixing, saving materials and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

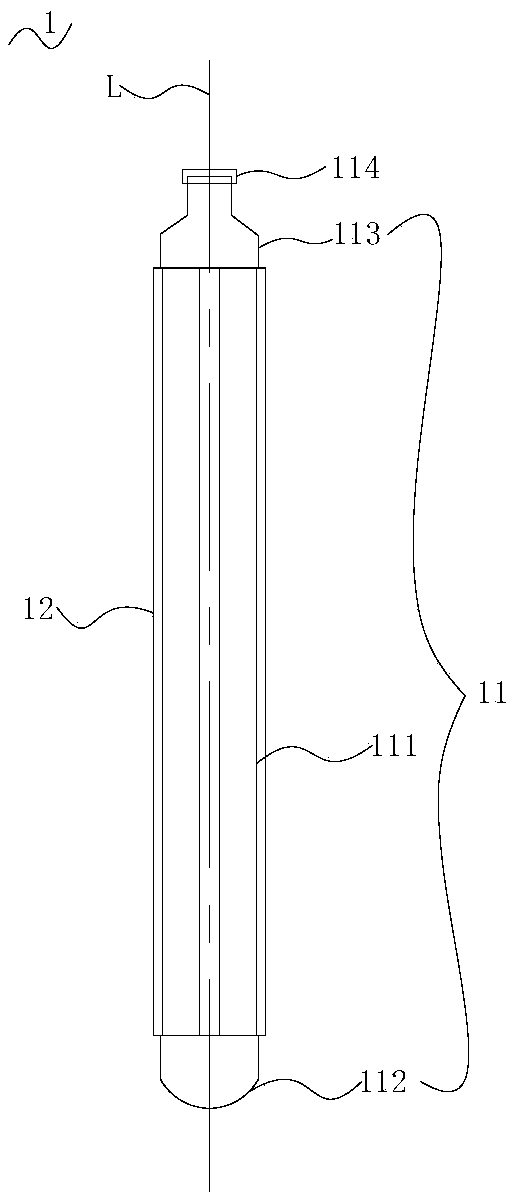

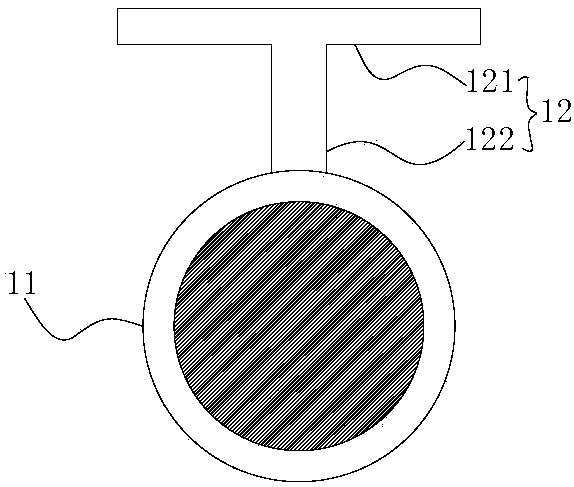

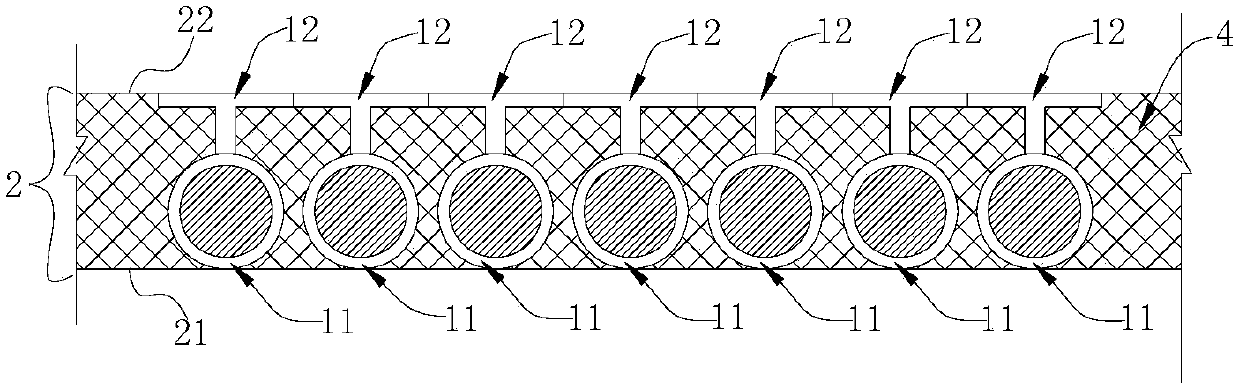

[0027] refer to figure 1 and figure 2 , the present embodiment provides an energy storage unit 1 including an energy storage body 11 and at least one seat 12 . Wherein, the energy storage main body 11 is columnar, and the energy storage main body 11 has an inner cavity, and the inner cavity is used for containing phase change materials. The support 12 is fixed to the energy storage main body 11 , and the support 12 has a bottom plate 121 , and the bottom plate 121 is parallel to the central axis L of the energy storage main body 11 . When the energy storage unit 1 of this embodiment is applied to the field of containers, generally a plurality of them are arranged in a row in the container, and the energy storage units 1 are usually filled with foam material 4 .

[0028] When installing the energy storage unit 1 of this embodiment, it is only necessary to direct the support 12 towards the area to be installed and make the bottom plate 121 adhere to the installation surface. ...

Embodiment 2

[0042] The energy storage unit 1 of the present embodiment is roughly the same as that of the embodiment 1, and its main difference is: refer to Figure 5 , the energy storage unit 1 is provided with a plurality of supports 12 , the energy storage unit 1 in this embodiment includes three supports 12 , and the three supports 12 are arranged at intervals along the circumference of the energy storage body 11 .

[0043] The structures of the energy storage body 11 and the support 12 in this embodiment are the same as those of the energy storage unit 1 in Embodiment 1, and will not be repeated here. In this embodiment, the three supports 12 are respectively one supporting support 12a and two blocking supports 12b. Wherein, the two stop supports 12b are symmetrically arranged on both sides of the support support 12a, and the two stop supports 12b are respectively arranged at both radial ends of the energy storage main body 11 .

[0044] When the energy storage unit 1 of this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com