Efficient drying hopper

A hopper and drying technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of poor drying effect, affecting the quality of materials, uneven heating of materials, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

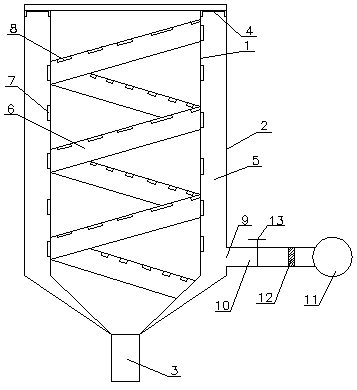

[0015] A high-efficiency drying hopper, comprising an inner layer hopper 1 and an outer layer hopper 2, the upper part of the inner layer hopper 1 is a cylinder, the outlet 3 at the lower part of the inner layer hopper 1 is welded to the bottom of the outer layer hopper 2, and the inner layer hopper 1 and the outer layer hopper 2 are provided with a connecting frame 4 at the upper end, and the two sides of the connecting frame 4 are respectively welded and connected with the inner layer hopper 1 and the outer layer hopper 2, and a cavity 5 is formed between the inner layer hopper 1 and the outer layer hopper 2, The inner layer hopper 1 is provided with a spiral tube 6, and the upper and lower ends of the spiral tube 6 are closed. The inner cavity of the inner cavity communicates with the cavity 5 through the through hole 7, and the surface of the spiral tube 6 is provided with several air outlets 8, and the side wall of the outer layer hopper 2 is provided with an air inlet 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com