Calibration method for 2D laser-binocular camera combined calibration

A binocular camera and joint calibration technology, applied in image data processing, instrumentation, computing and other directions, can solve the problems of low precision, difficult to achieve, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

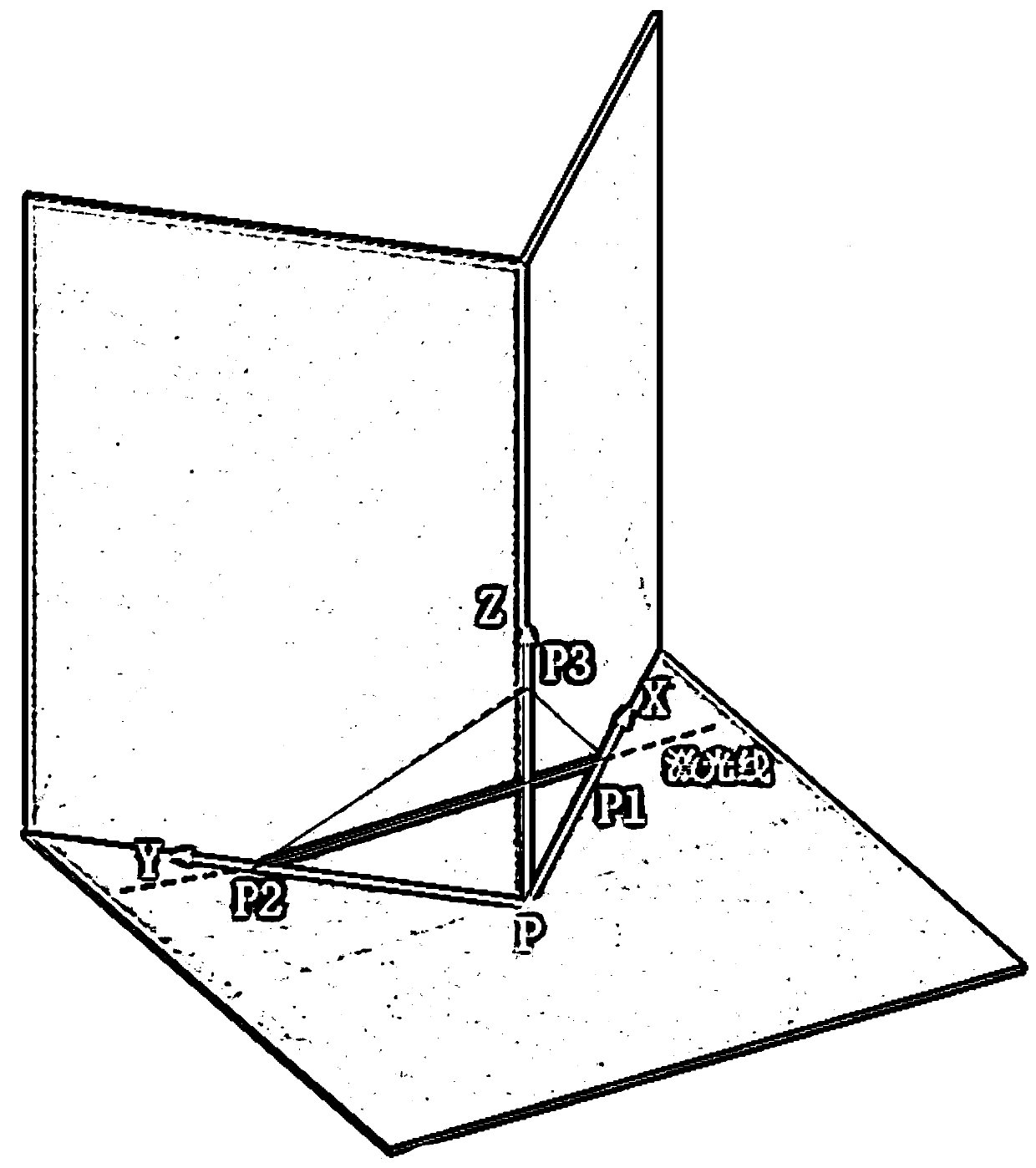

[0014] A calibration method for 2D laser-binocular camera joint calibration: install the 2D laser and the binocular camera on the equipment to be calibrated, and then set the calibration plate directly in front of the equipment to be calibrated. The calibration plate includes three mutually perpendicular planes, and intersect each other in pairs to form the corresponding X-axis, Y-axis, and Z-axis, and one of the planes is provided with a plane calibration feature, and then use the transformation relationship between the 2D laser coordinate system and the calibration plate coordinate system, and the binocular camera coordinates system and the plane calibration feature coordinate system, and the corresponding change relationship formed by the plane calibration feature coordinate system and the calibration plate coordinate system to obtain the transformation relationship between the 2D laser coordinate system and the binocular coordinate system, and complete the joint calibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com