Feeding method and device for improving operating efficiency of threshing process

A technology of operation efficiency and feeding device, which is applied in the field of feeding methods and devices for improving the operation efficiency of the threshing process, can solve the problems of high operation cost, material blocking of the threshing machine, affecting the operation efficiency of the threshing process, etc., so as to reduce the operation efficiency. Costs, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

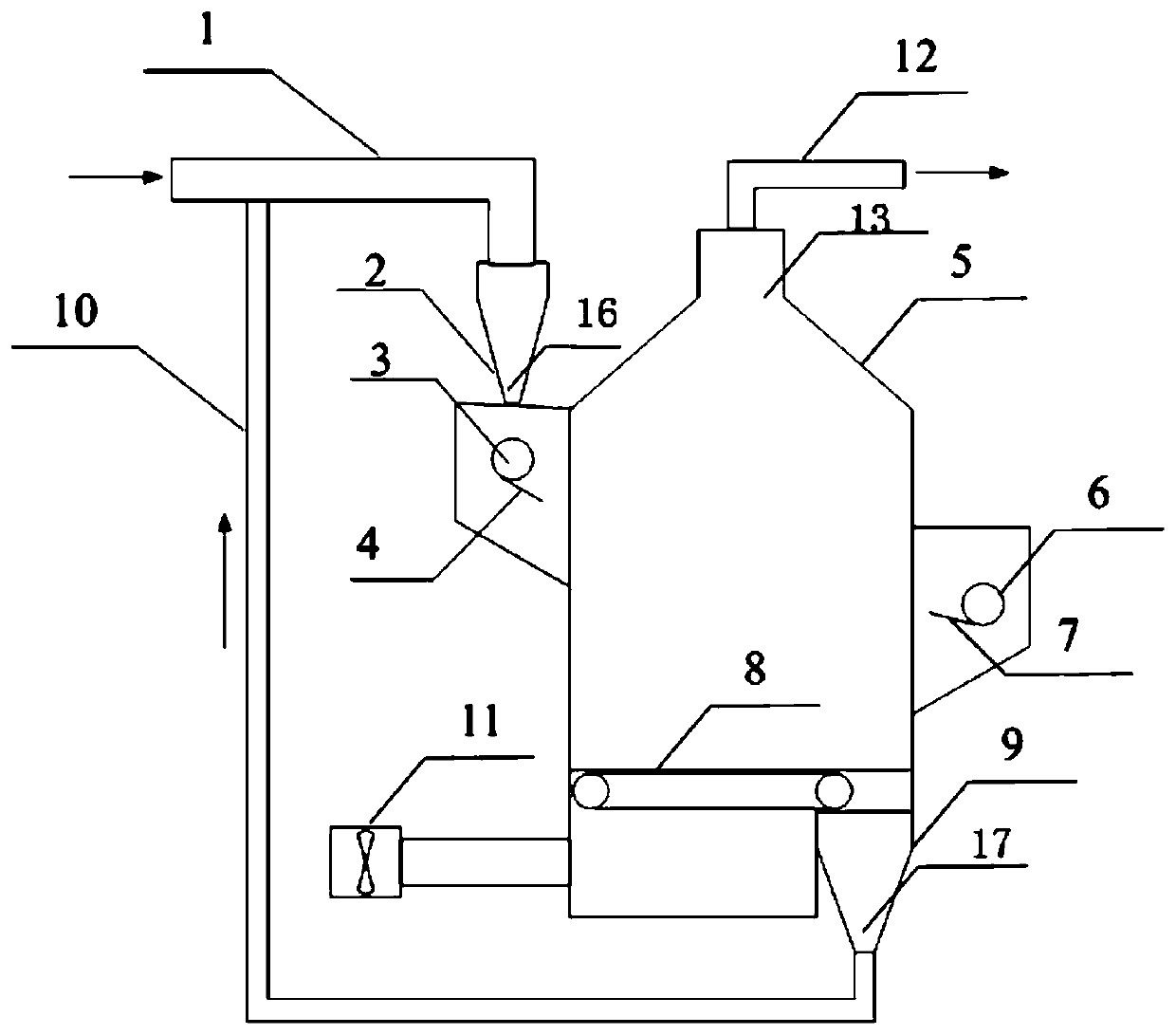

[0029] The first aspect of this embodiment relates to a feeding device for improving the operating efficiency of the beating process, including the following components:

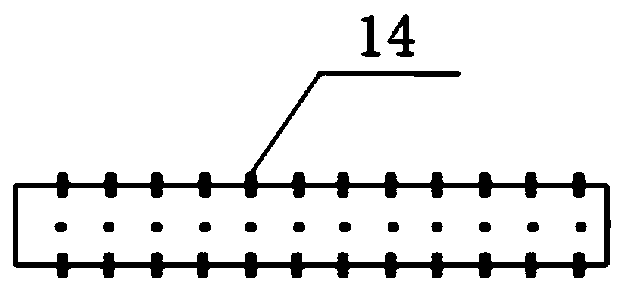

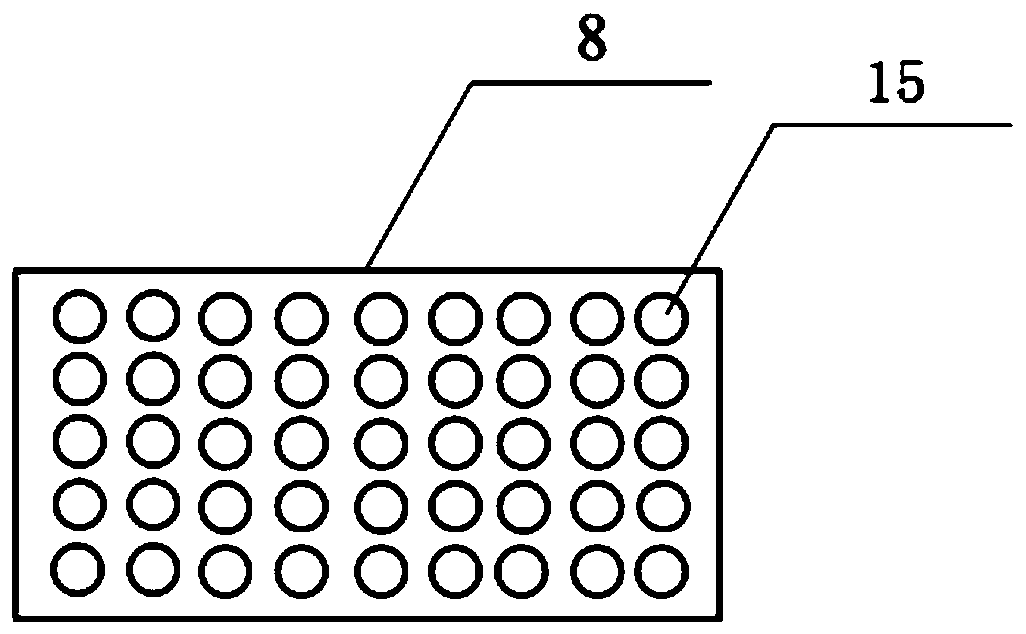

[0030] Dispersion chamber 5, its side wall is provided with the first distributing roller 3 and the second distributing roller 6, all is provided with spike 14 on the first distributing roller 3 and the second distributing roller 6, the first distributing roller 3 and the first guide The plate 4 is connected, the second dispersing roller 6 is connected with the second deflector 7, the top of the dispersing chamber 5 is provided with a first discharge port 13 and the first discharge port 13 is connected with the blade conveyor belt 12, and the bottom of the dispersing chamber 5 Be provided with conveying mesh belt 8 and discharge material dropper 9, be provided with the through-hole 15 that runs through this mesh belt on the conveying mesh belt 8, be provided with air inlet fan 11 at its bottom, the discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com