Automatic assembly equipment for fittings of power distributing cabinet

A technology for automatic assembly and power distribution cabinets, applied in metal processing equipment, assembly machines, manufacturing tools, etc., to achieve the effects of reducing recovery errors, high synchronization, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

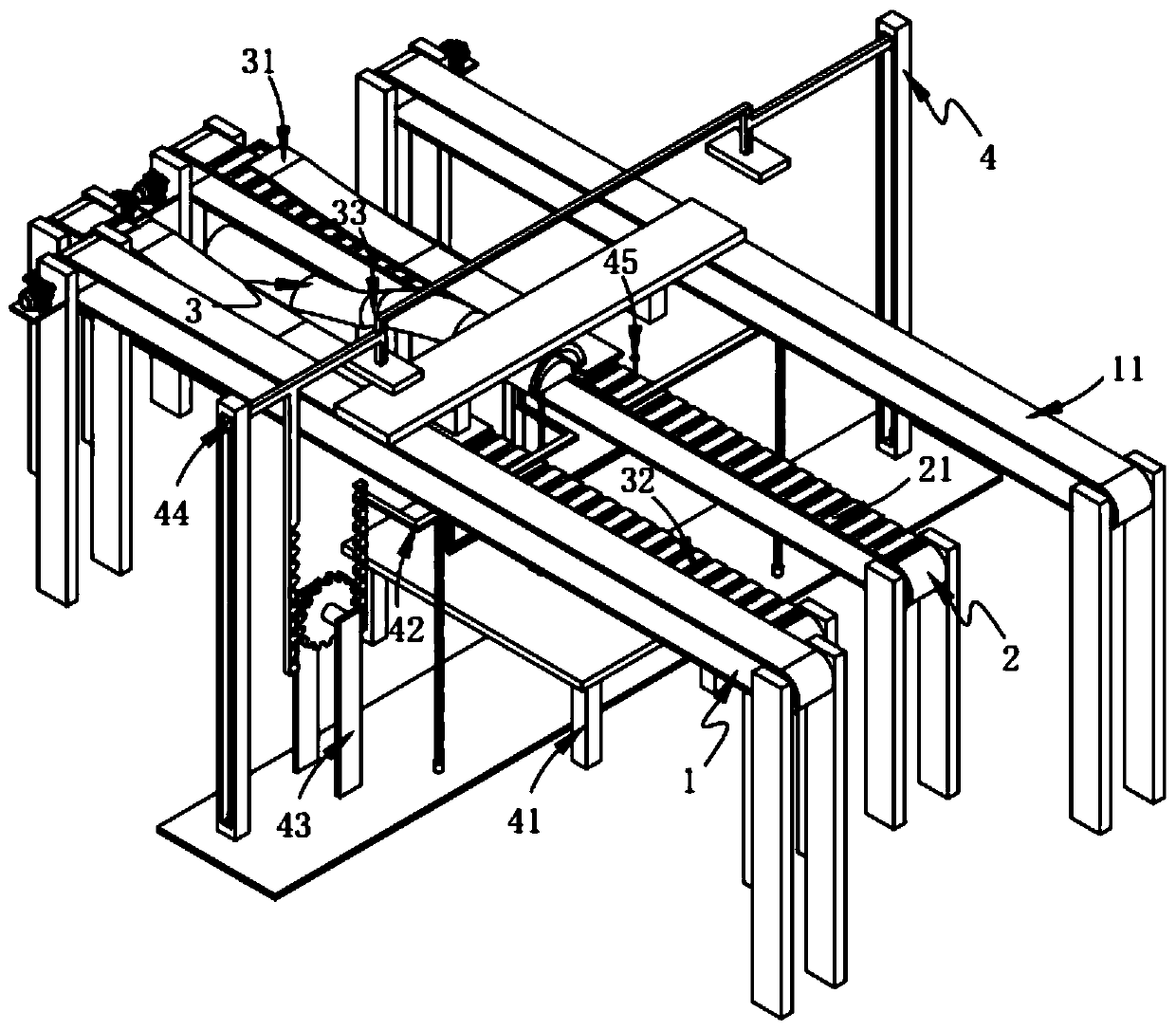

[0073] Such as figure 1 , Picture 10 , Picture 11 with Picture 12 As shown, an automatic assembly equipment for power distribution cabinet accessories includes:

[0074] The first feeding mechanism 1 is composed of two sets of symmetrically arranged transmission components a11;

[0075] The second feeding mechanism 2 is arranged between the two sets of transmission components a11, and it is composed of two sets of symmetrically arranged transmission components b21;

[0076] The forming mechanism 3, the forming mechanism 3 includes a positioning assembly 31 arranged above the transmission assembly b21, a pulling assembly 32 slidably arranged on the positioning assembly 31, and a component located between the two sets of the transmission assembly b21 Arch assembly 33; and

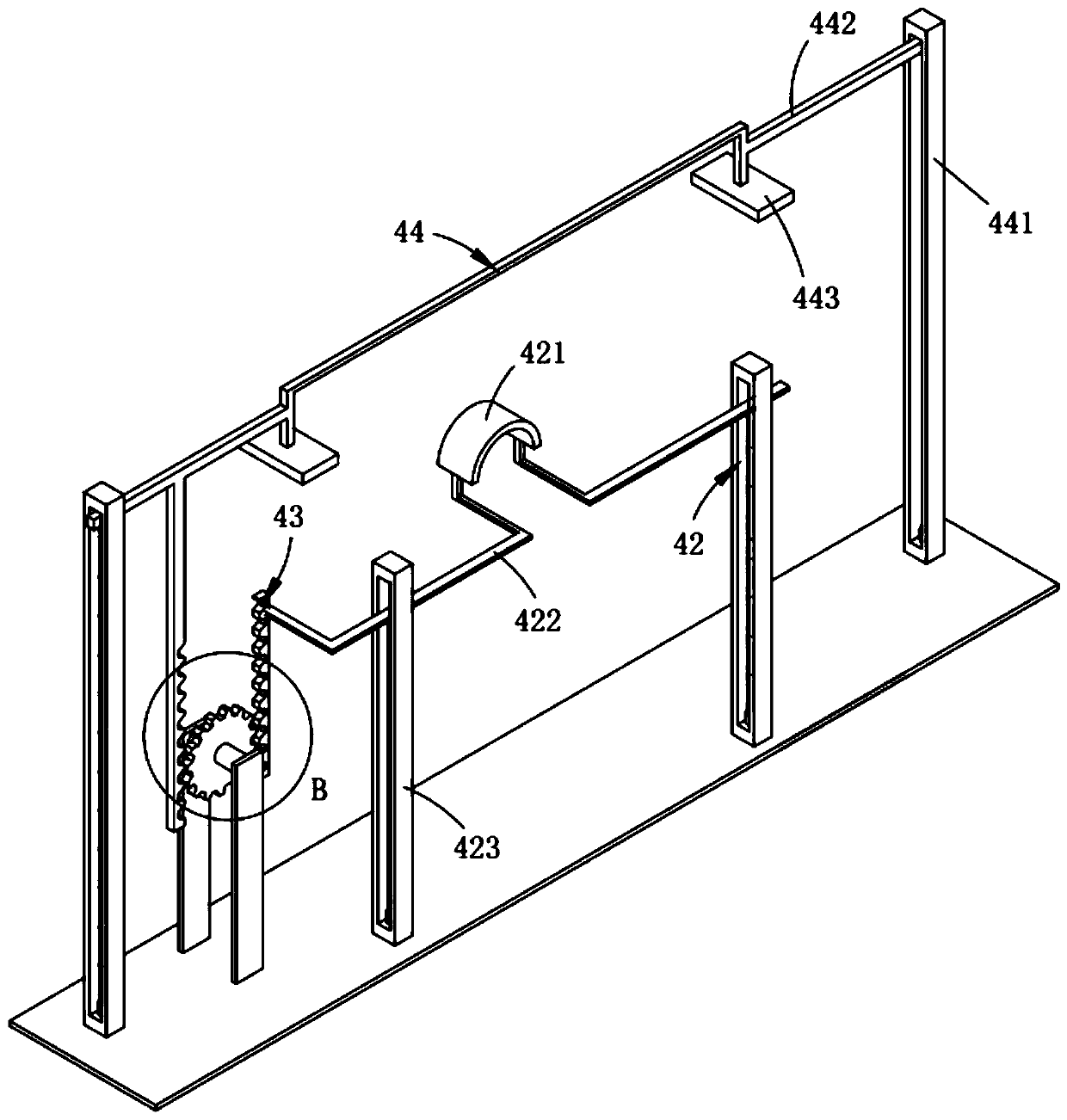

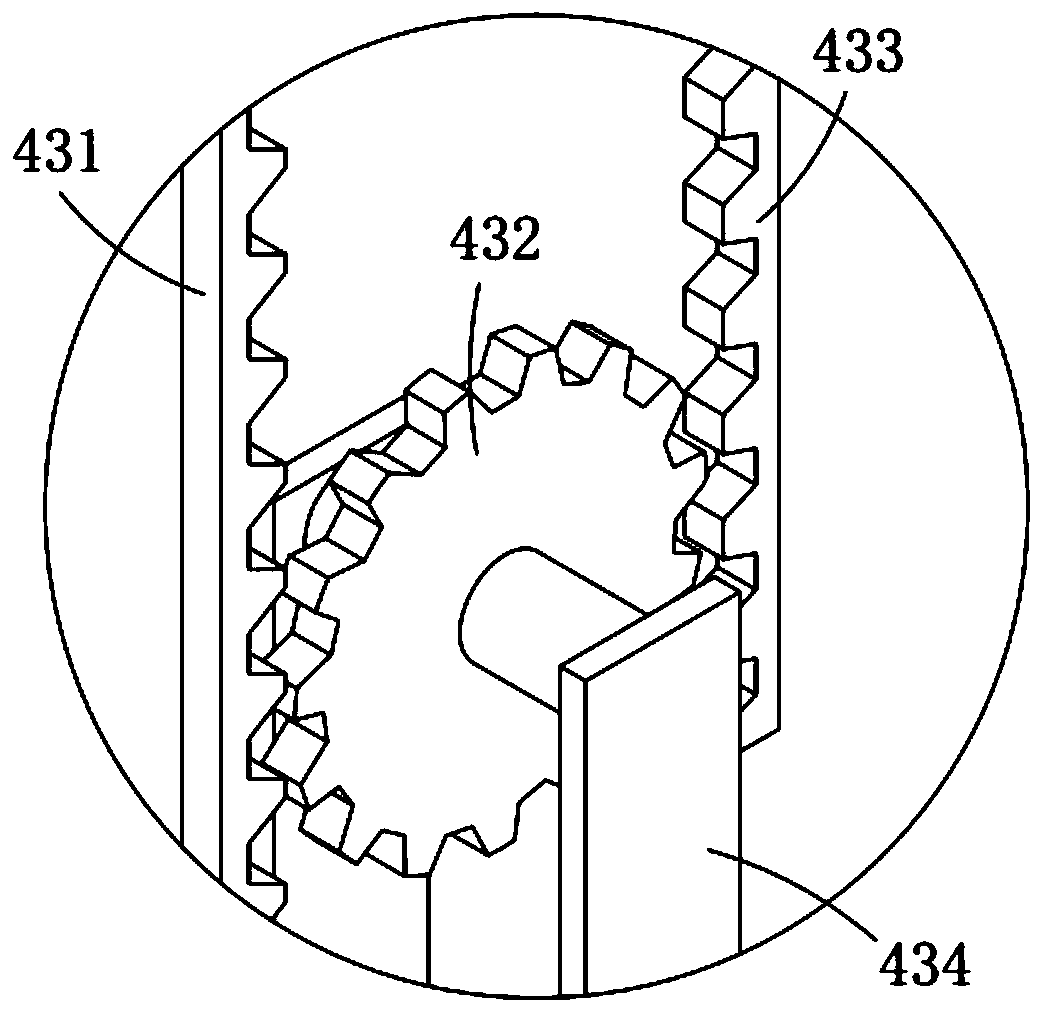

[0077] The tightening mechanism 4 includes a lifting assembly 41 mounted on the arching assembly 33, a hoop assembly 42 located above the lifting assembly 41 and below the transmission assembly a11, and mounted o...

Embodiment 2

[0126] Such as Image 6 As shown, the components that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0127] Further, such as Image 6 As shown, the pulling assembly 32 is arranged on the belt 114 and arranged in several groups at equal intervals along the length direction of the belt 114, which includes:

[0128] A sliding groove 321, the sliding groove 321 is arranged across the belt 114;

[0129] A sliding block 322, the sliding block 322 is slidably arranged on the sliding groove 321 and sliding along the length of the sliding groove 321, the sliding surface of the lower surface of the sliding block 322 is smoothly arranged;

[0130] Bumps 323, the bumps 323 are evenly arranged on the upper surface of the slider 322;

[0131] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com