Impression chamber for 3D printer

A technology of 3D printers and printing rooms, applied in the direction of 3D object support structures, manufacturing tools, processing environment adjustment, etc., can solve the problems of electronic and mechanical components with lengthy and expensive solutions, achieve effective protection, slow down cooling, and avoid complex The effect of system requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

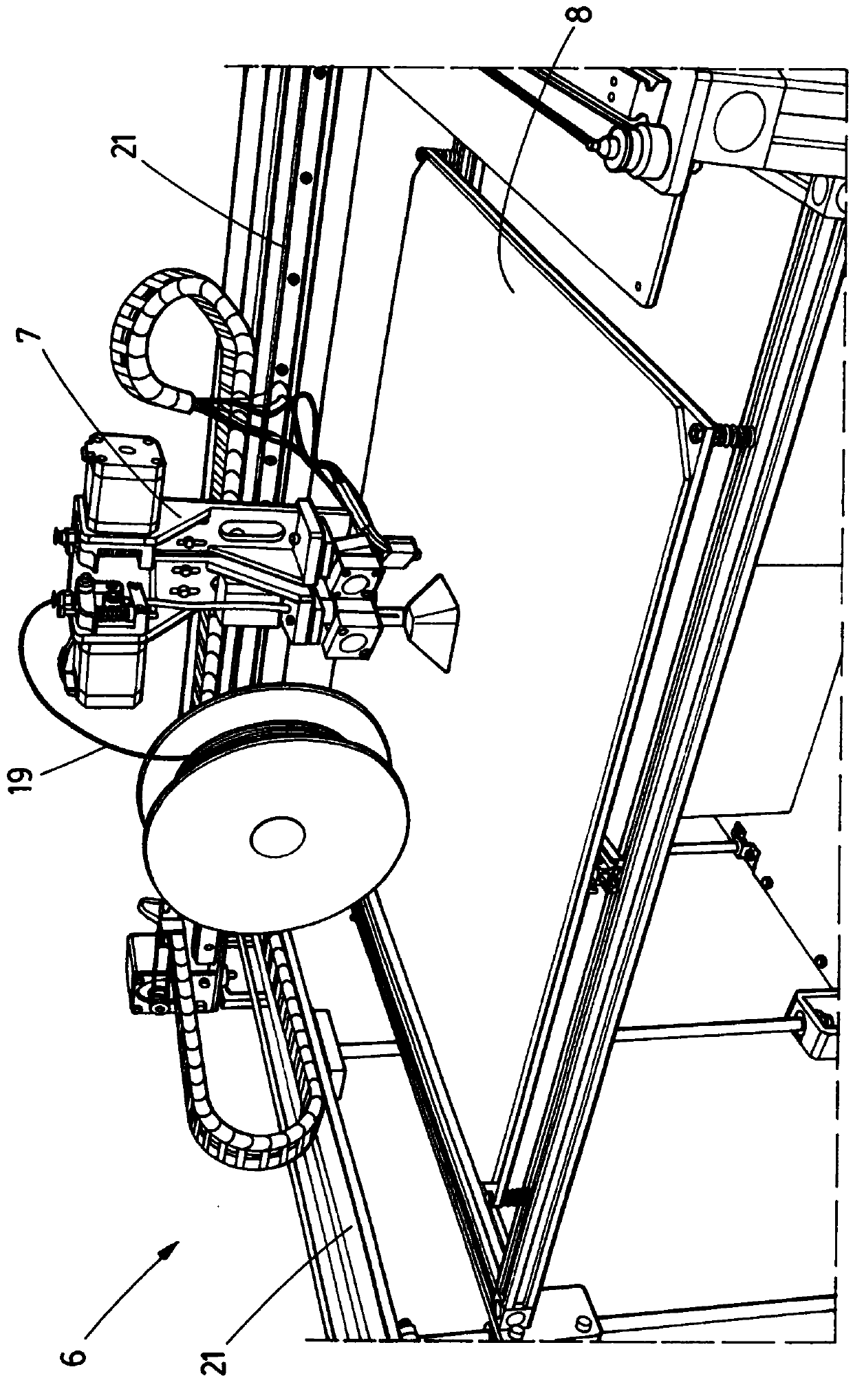

[0029] figure 1 A prior art fused filament fabrication 3D printer 6 is shown. As shown, the 3D printer 6 is adapted to receive a high-performance plastic filament 19 for heating the high-performance plastic filament and obtaining a high-performance plastic fuse for forming the workpiece 5 . The 3D printer 6 includes a print head 7 and a print bed 8 . The print head 7 is movable along longitudinal and transverse guides 21 for providing the successive layers of fuses required for forming the workpiece 5 . The printing bed 8 comprises a surface capable of supporting such layer deposition to form the workpiece 5 .

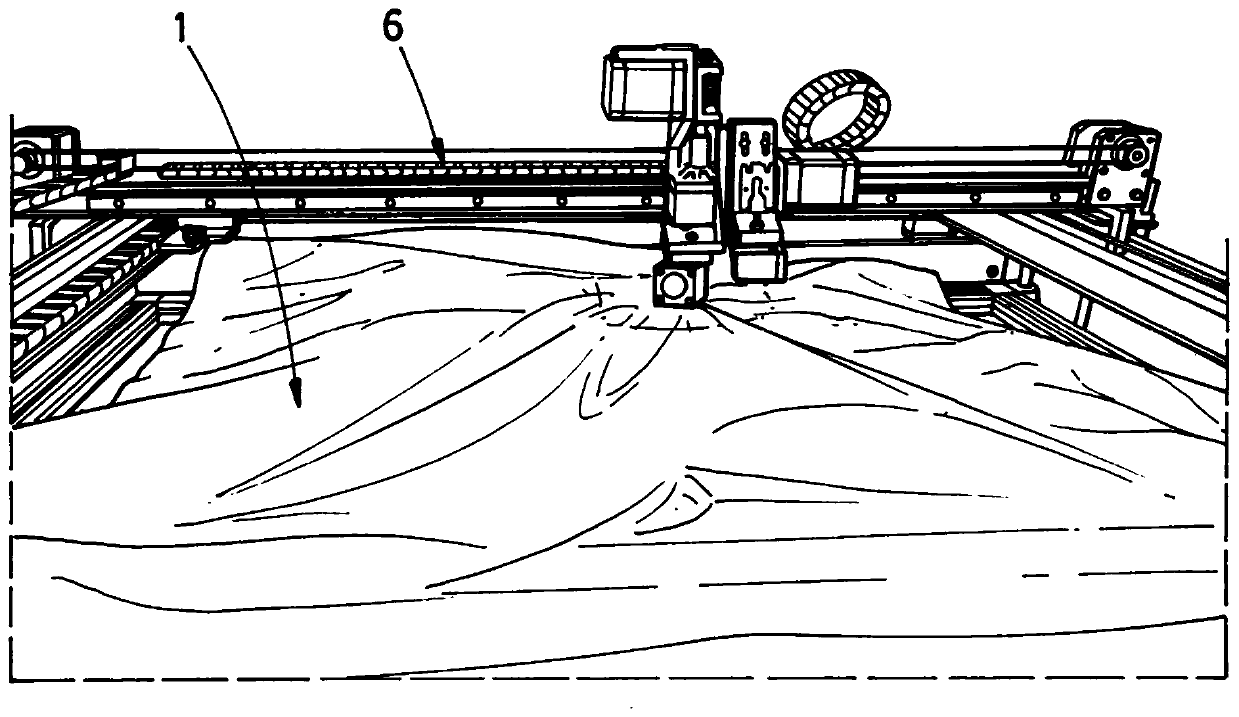

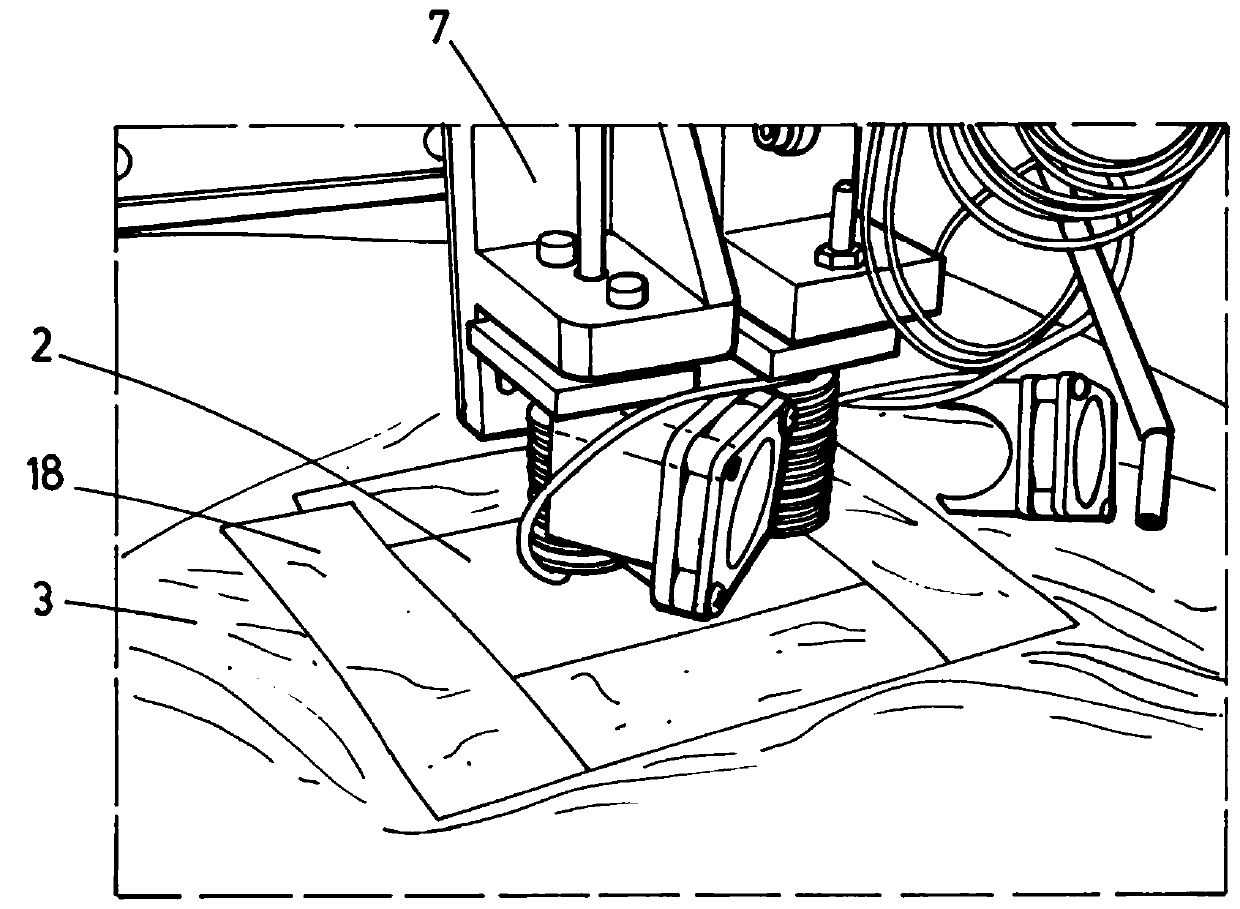

[0030] figure 2 and image 3 are shown for figure 1 A perspective and detailed view of the printing chamber 1 of the 3D printer 6 shown in . According to the invention, the printing chamber 1 comprises an insulating plate 2 for delimiting a closed printing space 20 in which a high-performance plastic workpiece 5 is to be printed and a first polyimide film 3 atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com