Exposed metal protection liquid and method in plasma enhanced chemical vapor deposition (PECVD) process

A technology for protecting liquid and metal, applied in metal material coating process, coating, gaseous chemical plating, etc., to achieve the effect of in place protection measures, ensure coating quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

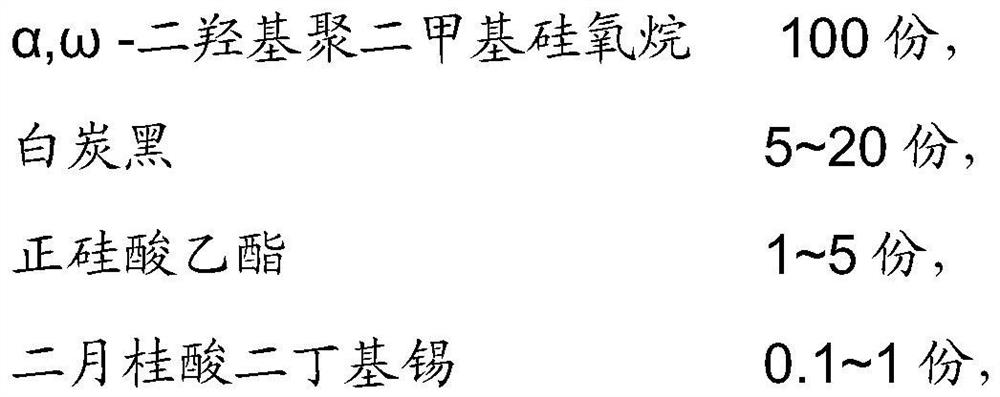

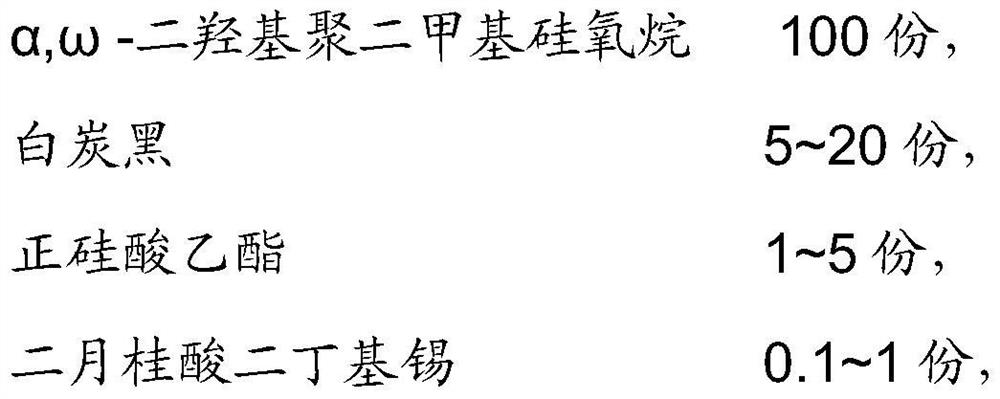

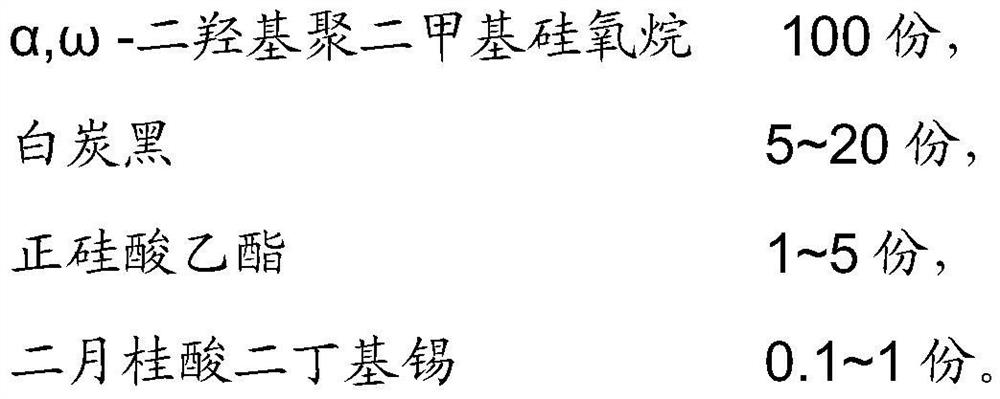

[0045] Step 1, prepare low-quality damage and easy-to-peel silicone rubber protection solution, wherein, α, ω-dihydroxy polydimethylsiloxane with molecular weight greater than or equal to 500g, 15g of white carbon black, 4g of tetraethyl orthosilicate, two Dibutyltin laurate 1g. First mix the masterbatch and white carbon black through a homogenizer, and then add dibutyltin dilaurate and ethyl orthosilicate in order after the mixing is complete; the last component needs to be fully stirred for 2 minutes after adding;

[0046] Step 2, apply the silicone rubber solution on the copper pad surface of the flat plate cable of the solar wing component to be coated with a fine brush, and apply it 1 or 2 times to ensure that the coating has no defects. After the coating is completed and cured at room temperature and pressure for 24 hours, the thickness of the protective film is measured to be 35 μm.

[0047] If there are water stains or hair debris on the surface of the cable (non-pad ...

Embodiment 2

[0052] Step 1, prepare a low-quality and easy-to-peel silicone rubber protection solution, including 100g of α,ω-dihydroxypolydimethylsiloxane with a molecular weight greater than or equal to 500, 20g of white carbon black, 3g of tetraethyl orthosilicate, and dilaurate Dibutyltin acid 1g. First mix the masterbatch and white carbon black through a homogenizer, and then add dibutyltin dilaurate and ethyl orthosilicate in sequence after the mixing is complete; after the last component is added, it needs to be fully stirred for 2 minutes.

[0053] Step 2, apply the silicone rubber solution on the copper pad surface of the flat plate cable of the solar wing component to be coated with a fine brush, and apply it 1 or 2 times to ensure that the coating has no defects. After the coating is completed and cured at room temperature and pressure for 24 hours, the thickness of the protective layer is measured to be 27 μm.

[0054] If there are water stains or hair debris on the surface of...

Embodiment 3

[0059] Step 1, preparing a low-quality and easy-to-peel silicone rubber protective solution, wherein, α, ω-dihydroxy polydimethylsiloxane with a molecular weight greater than or equal to 500g, 5g of white carbon black, 1g of tetraethyl orthosilicate, two Dibutyltin laurate 0.1g. First mix the masterbatch and white carbon black through a homogenizer, and then add dibutyltin dilaurate and ethyl orthosilicate in order after the mixing is complete; after the last component is added, it needs to be fully stirred for 5 minutes.

[0060] Step 2: Apply the silicone rubber solution on the surface of the copper foil of the solar wing furnace cable with a fine brush, and apply it 1 or 2 times to ensure that the coating has no defects. After the coating is completed and cured at room temperature and pressure for 24 hours, the workpiece is put into the PECVD equipment and vacuumed to 10 - 3 Pa hold the pressure for 24 hours before coating.

[0061] Step 3. After PECVD is completed, use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull value | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Pull value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com