All-rubber covered 3D hot bending glass protective sheet

A protective sheet and glass technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of easy breakage, inability to curl, poor softness of tempered film, etc., to achieve unbreakable, good flexibility, and protect mobile phones Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

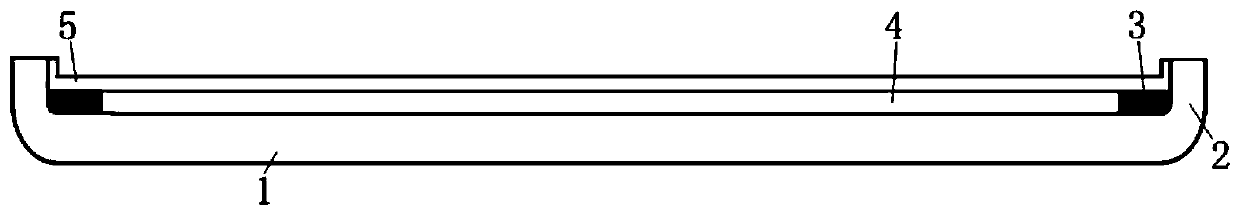

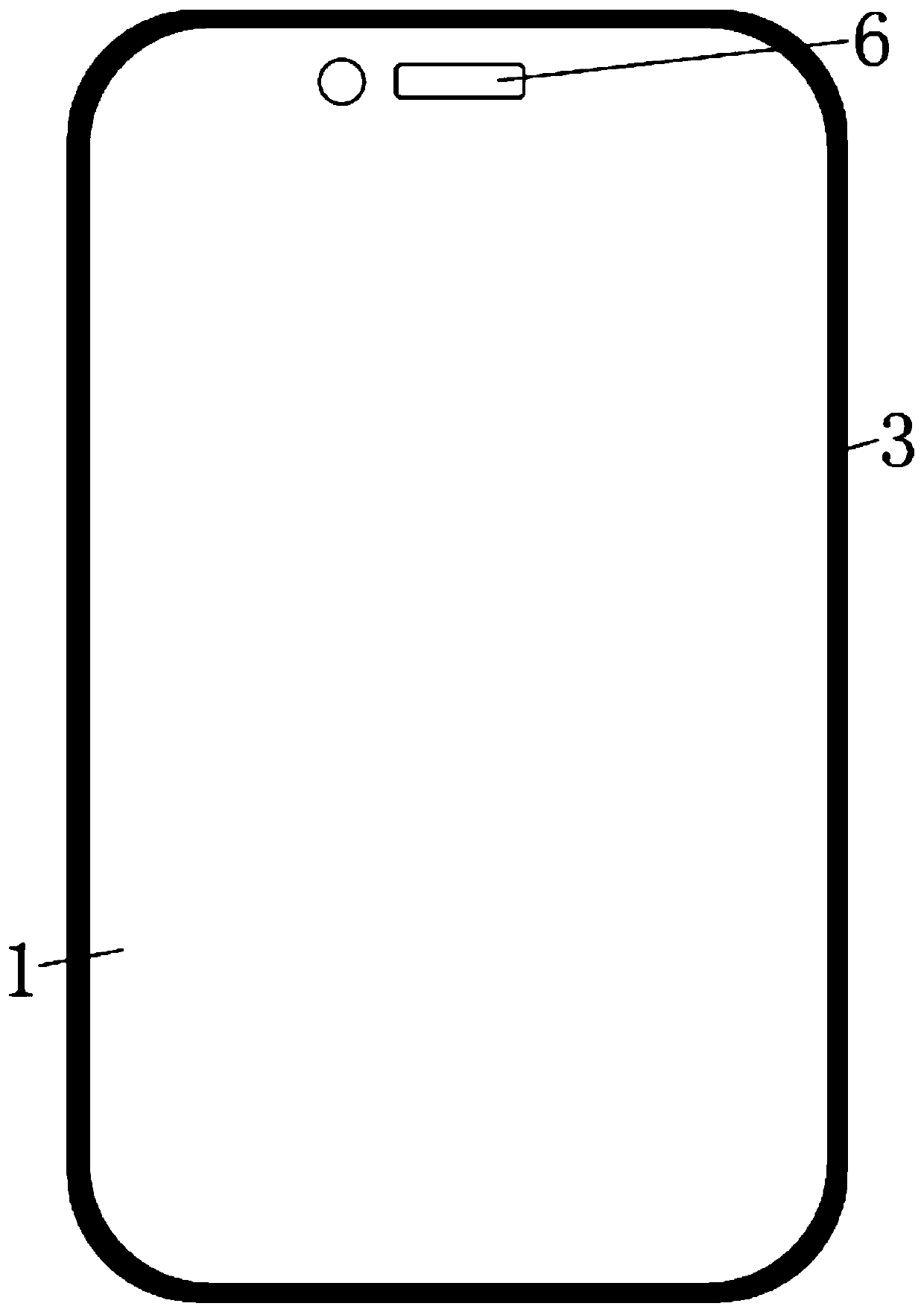

[0017] A full-glue covered 3D hot-bending glass protection sheet, comprising a glass protection sheet main body plane 1, an arc-shaped peripheral portion 2, an ink layer 3, a first adhesive layer 4, and a second adhesive layer 5, and the glass protection sheet main body plane 1 Formed integrally with the arc-shaped peripheral part 2, the thickness of the protective glass sheet is 0.2 mm, and the protective glass sheet of this thickness can be curled to 720°, which can not only ensure the hardness of the protective glass sheet itself, but also have good softness The glass protection sheet can be better attached to the screen of the mobile phone. The ink layer 3 surrounds the edge of the main plane 1 of the glass protection sheet and is attached to the inner side of the arc-shaped peripheral part 2. The first adhesive layer 4 is attached On the main plane 1 of the glass protection sheet, the second adhesive layer 5 is attached to the first adhesive layer 4 and the ink layer 3 at ...

specific Embodiment 2

[0024] A full-glue covered 3D hot-bending glass protection sheet, comprising a glass protection sheet main body plane 1, an arc-shaped peripheral portion 2, an ink layer 3, a first adhesive layer 4, and a second adhesive layer 5, and the glass protection sheet main body plane 1 Formed integrally with the arc-shaped peripheral part 2, the thickness of the protective glass sheet is 0.22 mm. The protective glass sheet of this thickness can be curled to 650°. While ensuring the hardness of the protective glass sheet itself, it can also have good softness. The glass protection sheet can be better attached to the screen of the mobile phone. The ink layer 3 surrounds the edge of the main plane 1 of the glass protection sheet and is attached to the inner side of the arc-shaped peripheral part 2. The first adhesive layer 4 is attached On the main plane 1 of the glass protection sheet, the second adhesive layer 5 is attached to the first adhesive layer 4 and the ink layer 3 at the same t...

specific Embodiment 3

[0031] A full-glue covered 3D hot-bending glass protection sheet, comprising a glass protection sheet main body plane 1, an arc-shaped peripheral portion 2, an ink layer 3, a first adhesive layer 4, and a second adhesive layer 5, and the glass protection sheet main body plane 1 Formed integrally with the arc-shaped peripheral part 2, the thickness of the protective glass sheet is 0.25 mm. The protective glass sheet of this thickness can be curled to 540°, which ensures the hardness of the protective glass sheet itself and also has good softness. The glass protection sheet can be better attached to the screen of the mobile phone. The ink layer 3 surrounds the edge of the main plane 1 of the glass protection sheet and is attached to the inner side of the arc-shaped peripheral part 2. The first adhesive layer 4 is attached On the main plane 1 of the glass protection sheet, the second adhesive layer 5 is attached to the first adhesive layer 4 and the ink layer 3 at the same time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com