Ultra-smooth basic structure as well as device for testing ultra-smooth friction coefficient of solid

A basic structure and super-slip technology, which is applied in the field of structural super-slip, can solve the problems of difficult non-destructive separation, difficult super-slip island-shaped objects, and increased test costs, so as to improve test speed, realize repeated use, and reduce test costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

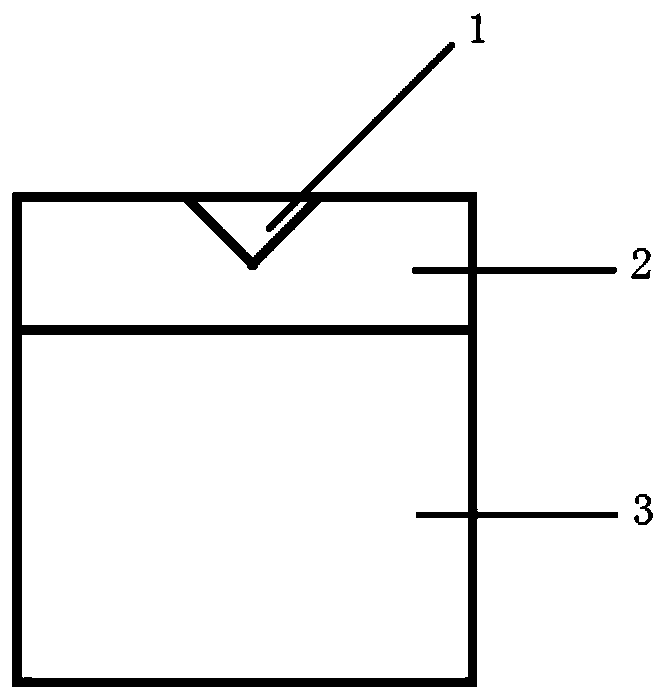

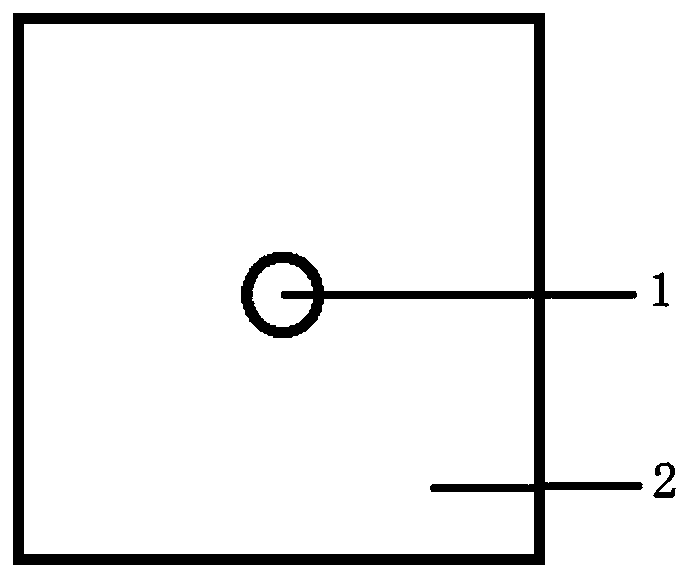

[0023] Embodiment one, such as Figure 1-2 As shown, a supersmooth basic structure is provided, including a substrate and a plurality of island structures located on the substrate, wherein each island structure includes an island cover 2 and an island body 3 with an atomically smooth surface, and the island The cover 2 is located on the upper surface of the island body 3 , and the upper surface of the island cover 2 is provided with the connecting unit 1 . The island body 3 has at least one super-slippery shear surface, and the upper and lower contact surfaces of the super-slippery shear surface are in a non-commensurate state.

[0024] The end of each island body 3 has an island cover 2, and the island cover 2 may be SiO 2 Protective layer, SiO deposited on the substrate by plasma chemical vapor deposition for patterning and etching of island structures during processing 2 The protective layer may have a thickness of 50nm-500nm.

[0025] Preferably, the substrate is graphi...

Embodiment 2

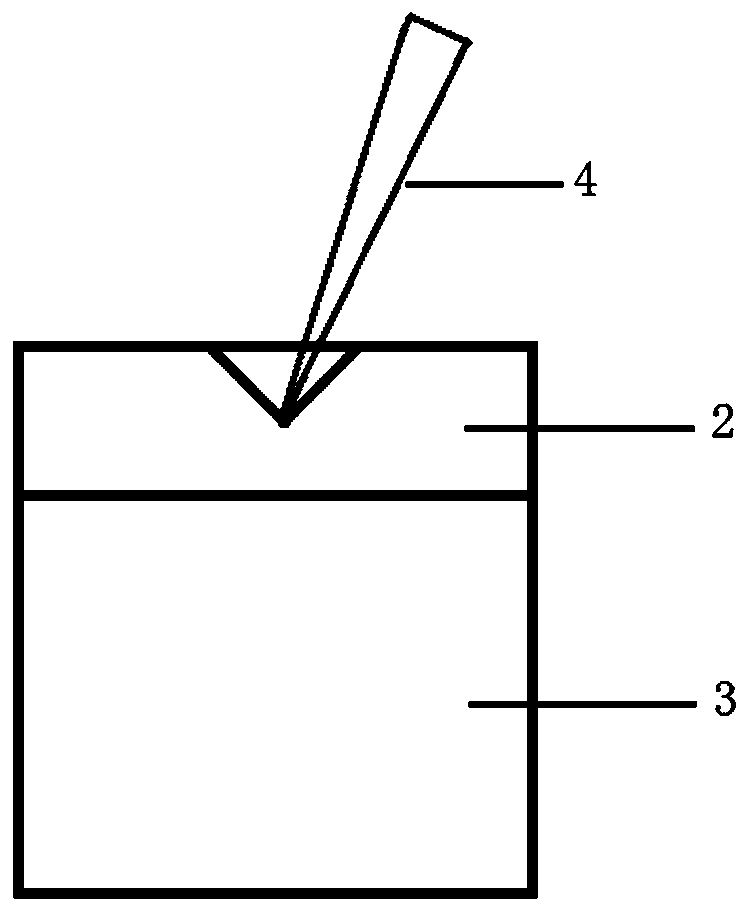

[0030] Embodiment two, such as image 3 As shown, a device for testing the coefficient of friction of solid superslip, which includes a pushing part 4 and the above-mentioned superslip basic structure, and the tip of the pushing part 4 is detachably connected with the connecting unit 2 . Using the device in the test of the solid superslip friction coefficient can better fix the superslip island body such as graphite island, and can control the movement of the island body more flexibly and accurately by pushing the parts, which improves the friction coefficient of the superslip device Test efficiency, in addition, after the test is completed, the needle tip and the super slippery island can be separated quickly and conveniently, which realizes the reuse of the super slippery island, simplifies the operation steps, improves the test speed, and greatly reduces the test time. cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com