An aero-engine high-pressure rotor assembly error prediction method

A technology for aero-engines and high-pressure rotors, applied in the field of mechanical assembly, can solve problems such as complexity, long calculation time of finite element method, low prediction accuracy of rigid body error transfer analysis method, etc., to improve assembly efficiency, fast calculation speed, and high prediction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

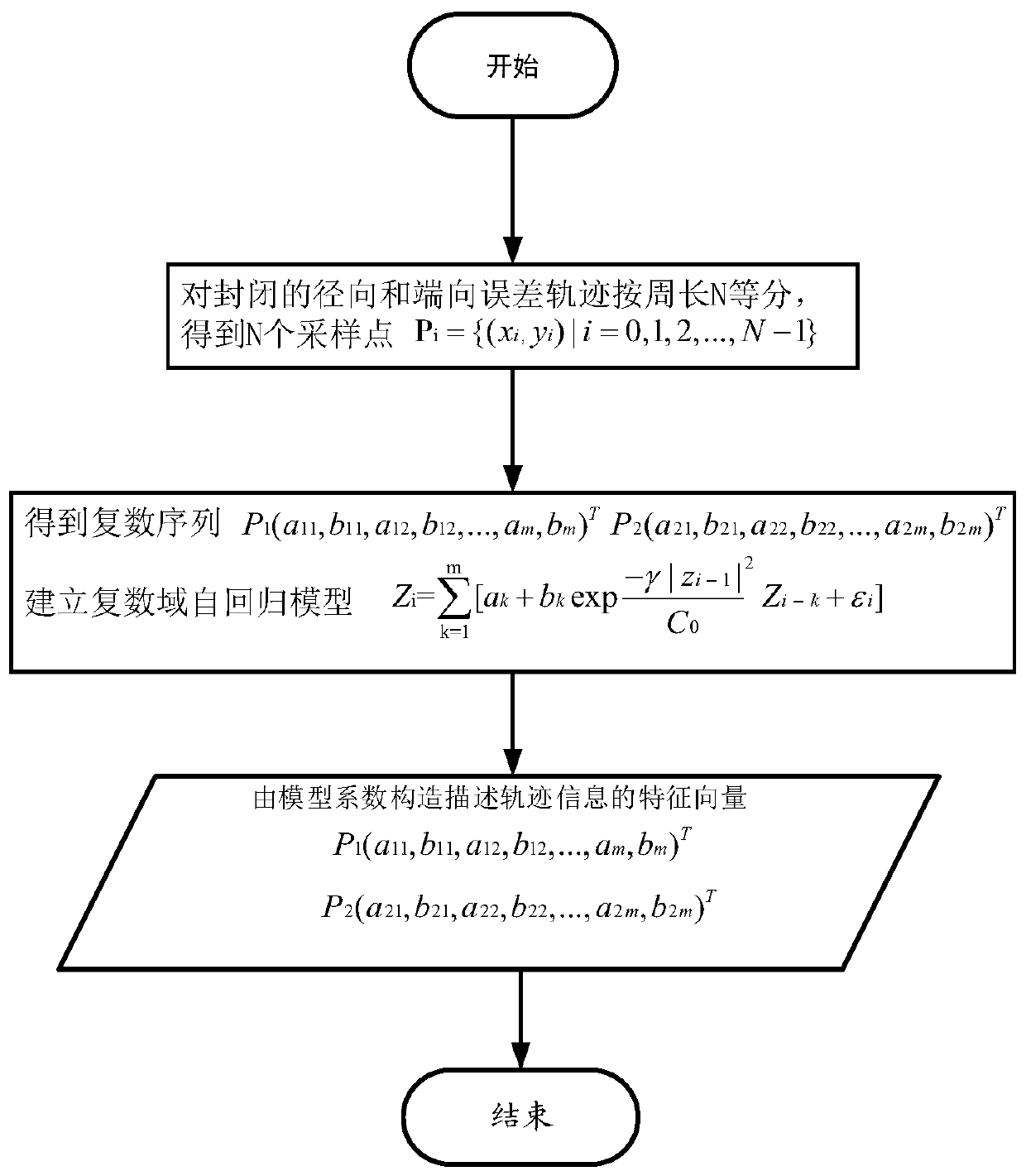

[0034] see figure 1 , the aero-engine high-pressure rotor assembly error prediction method provided by the present invention comprises the following steps:

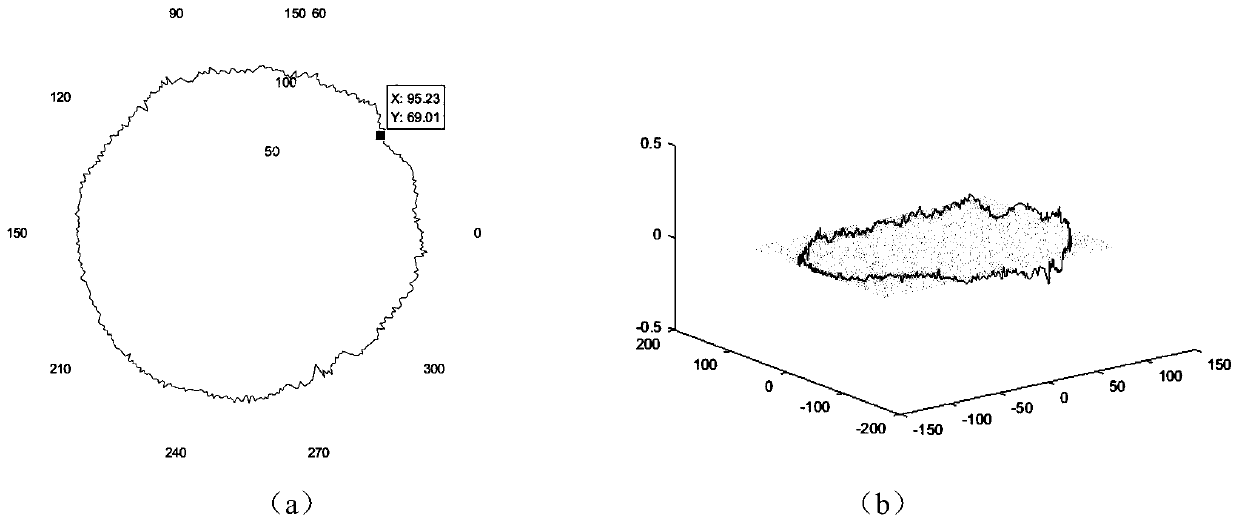

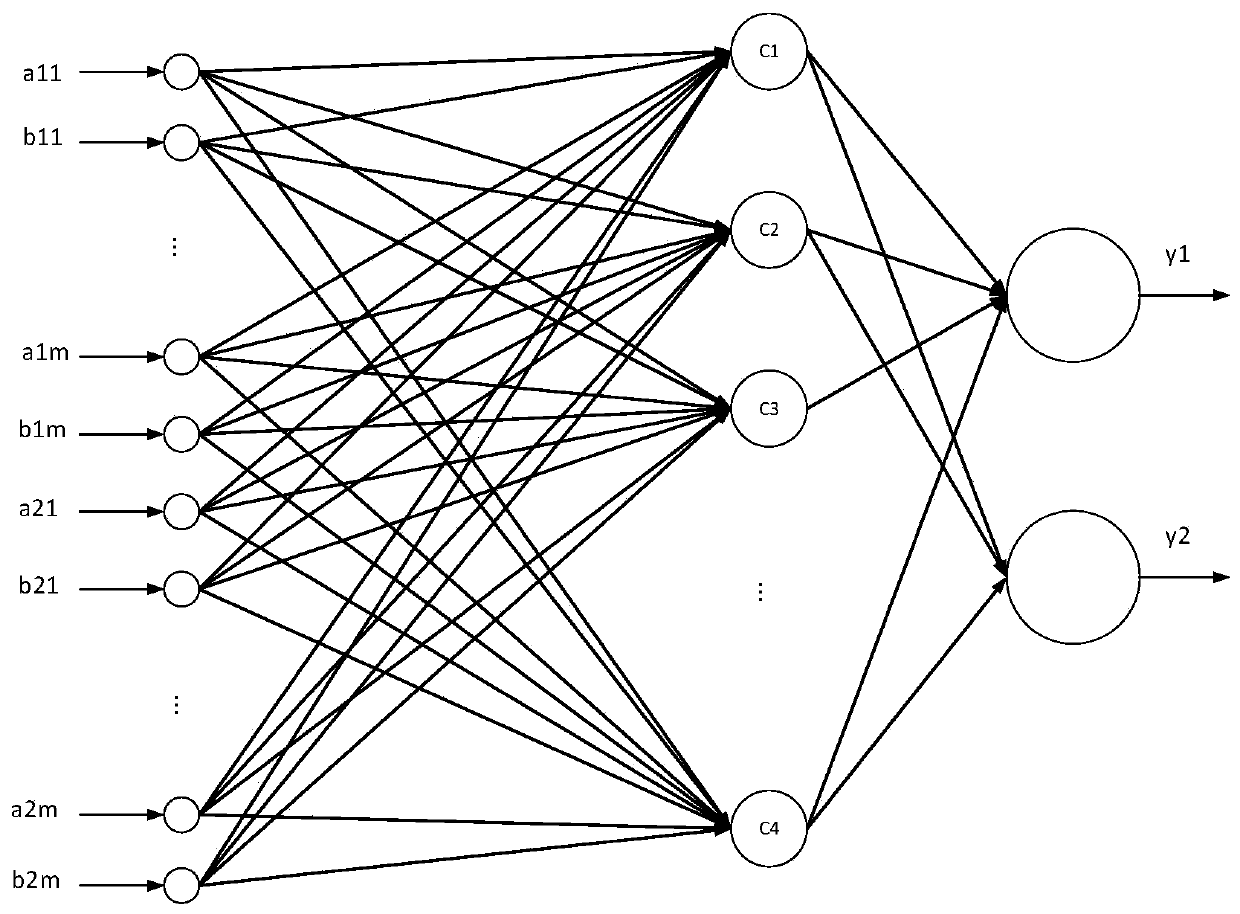

[0035] Step 1: Carry out image recognition on the measured radial and end error contour tracks of the spigot fitting surfaces of the rotor parts to establish a complex domain autoregressive model scheme. First measure the radial runout error and the end runout error of the mating surface to obtain the contour track of the error in the two directions (such as figure 2 ), after dividing the perimeter of the contour into N equal parts, N sampling points are obtained, and the sampling point P i ={(x i ,y i )|i=0, 1, 2, ..., N-1} If the coordinate sequence of the relative contour centroid is represented by a complex number, there will be a complex number sequence {z i =x i +jy i |i=0, 1, 2, ..., N-1}, (the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com