Industrial intelligent optimized energy saving system based on diagnosis and analysis of key energy consumption equipment model

A diagnostic analysis and equipment model technology, applied in the direction of registering/indicating machine work, instruments, registering/indicating, etc., can solve the lack of human-machine communication, the inability of users to know the specific components of the fault and the method of troubleshooting, and affect the production and operation of enterprises Benefits and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

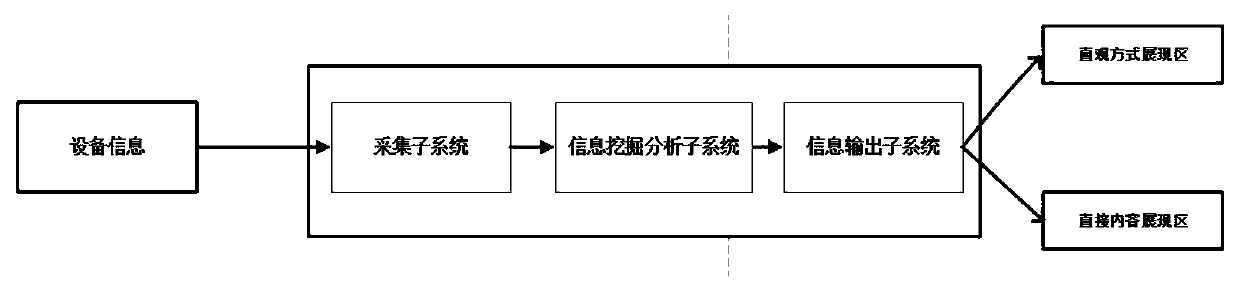

[0019] Such as figure 1 shown. An industrial intelligent optimized energy-saving system based on the diagnosis and analysis of key energy-consuming equipment models in the present invention takes knowledge management as the core, and is supported by application systems such as state monitoring, equipment inspection, intelligent diagnosis reasoning, and intelligent maintenance decision support. The operation status is coordinated to carry out equipment diagnosis and maintenance work, including the fault information collection subsystem, fault information analysis subsystem, and fault information output subsystem.

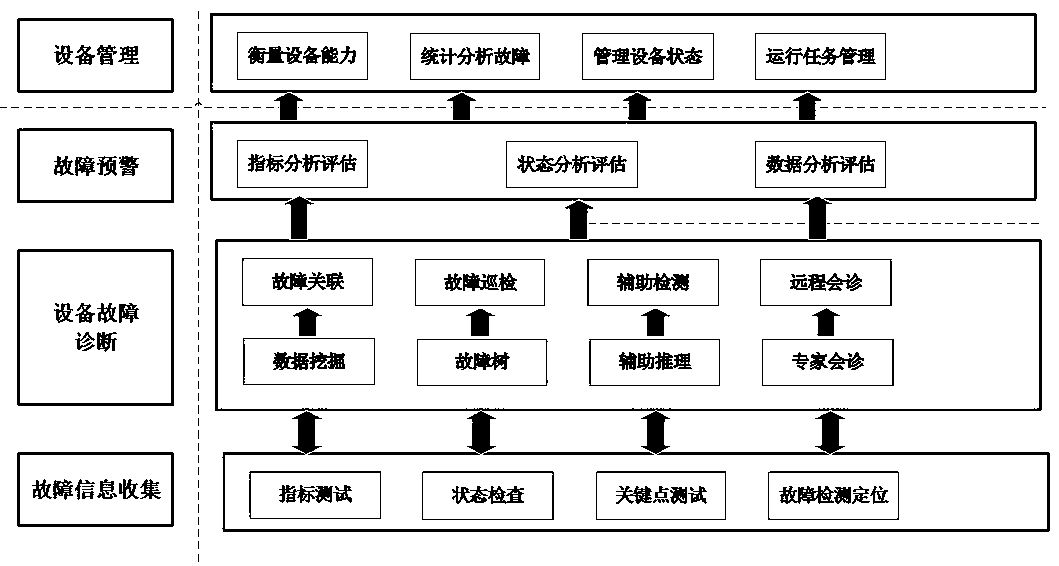

[0020] Such as figure 2 shown. The fault information collection subsystem is to collect and organize various information, and at the same time do a good job in information reading, storage of recorded content, and addition of new content, including automatic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com