A solar panel with nano-self-cleaning coating can improve the power generation of photovoltaic modules

A photovoltaic module and solar panel technology, applied in the field of solar panels, can solve the problems of reducing the solar energy conversion efficiency of photovoltaic solar panels, reducing the light-receiving area of photovoltaic solar panels, affecting the conversion efficiency of photovoltaic solar panels, etc. Conversion efficiency, the effect of reducing the amount of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

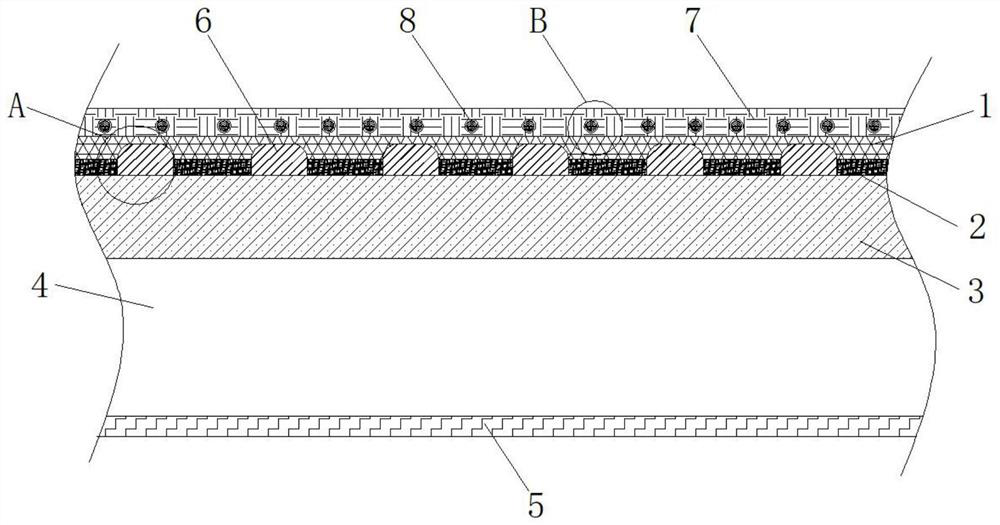

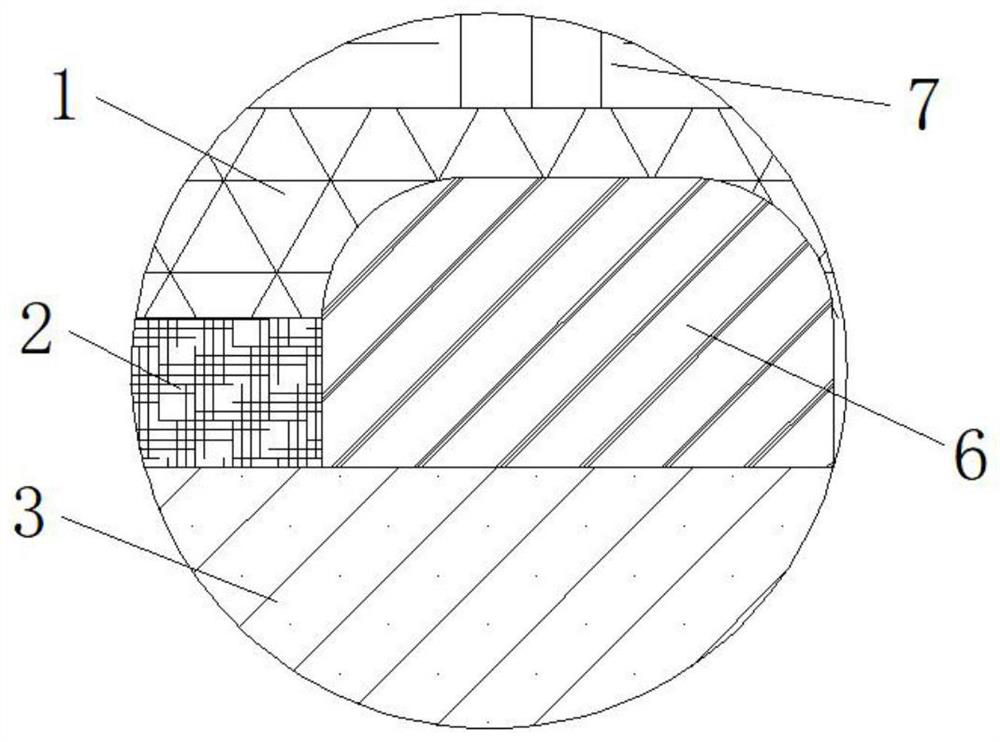

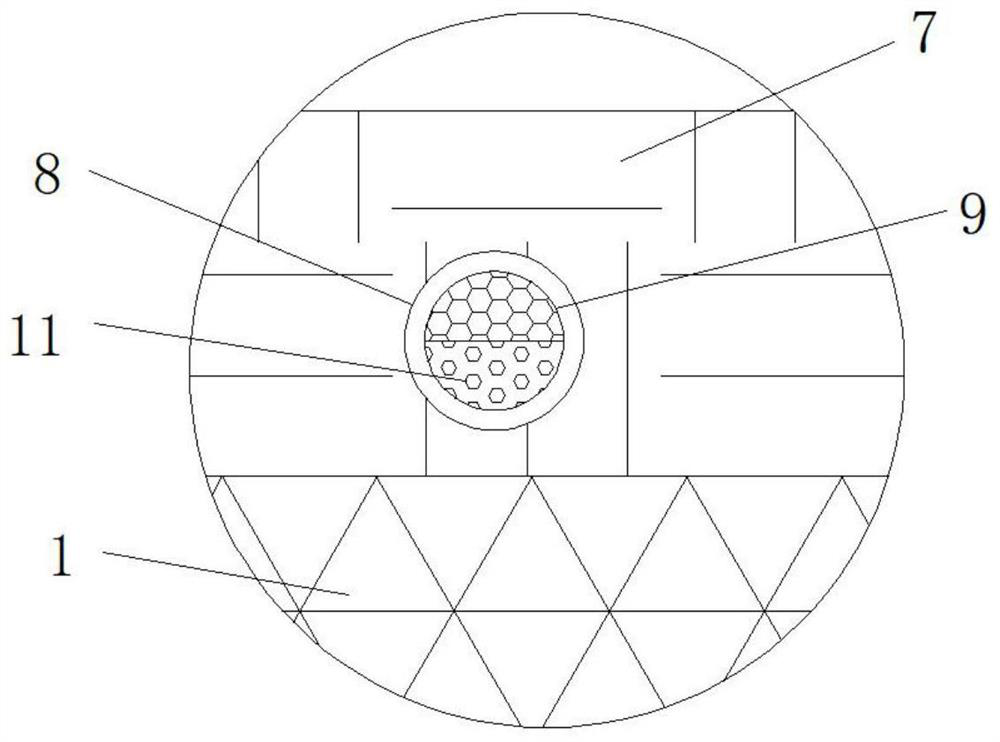

[0038] see Figure 1-4 , a solar panel with a nano self-cleaning coating that can increase the power generation of photovoltaic modules, comprising a front screen white glass plate 1, a rear electrode substrate 5 is provided on the lower side of the front screen white glass plate 1, a front screen white glass plate 1 and An electrode N-type silicon plate 3 and an electrode P-type silicon plate 4 are sequentially arranged between the rear electrode electric substrates 5, and the lower end of the electrode N-type silicon plate 3 is closely attached to the upper end of the electrode P-type silicon plate 4. A plurality of front electrode circuit wires 6 are arranged between the screen white glass plate 1 and the electrode N-type silicon plate 3, and the upper and lower ends of the front electrode circuit wire 6 are respectively closely attached to the front screen white glass plate 1 and the electrode N-type silicon plate 3 The upper side of the electrode N-type silicon plate 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com