Passenger car tire burst emergency safety device

A technology for safety devices and passenger cars, which is applied to vehicle parts, tire parts, transportation and packaging, etc., and can solve the problems that are difficult to meet the requirements of large-scale assembly and maintenance markets of OEMs, poor product versatility, and heavy product weight. and other problems, to achieve the effect of quick disassembly and assembly process, economical fuel consumption and reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

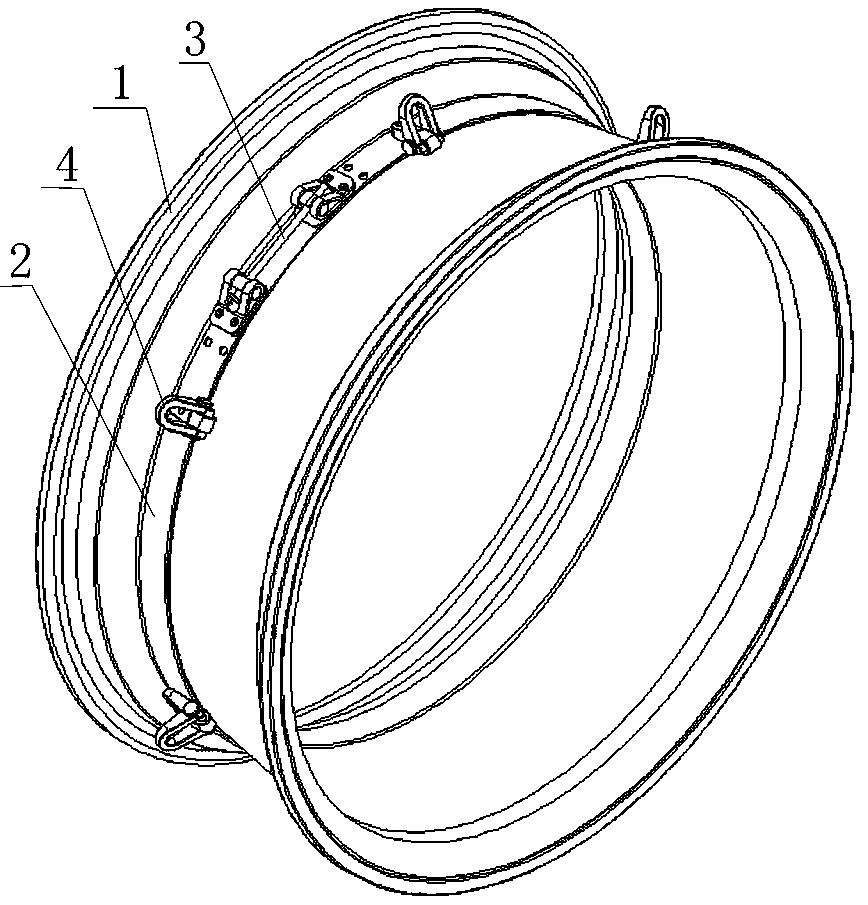

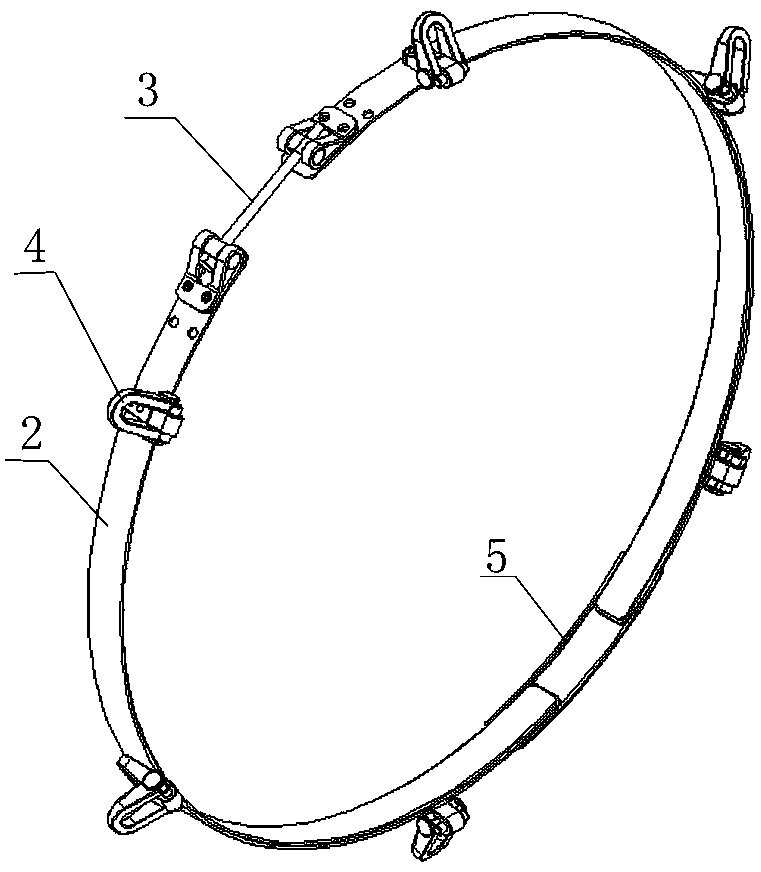

[0032] The present invention as Figure 1-9 shown.

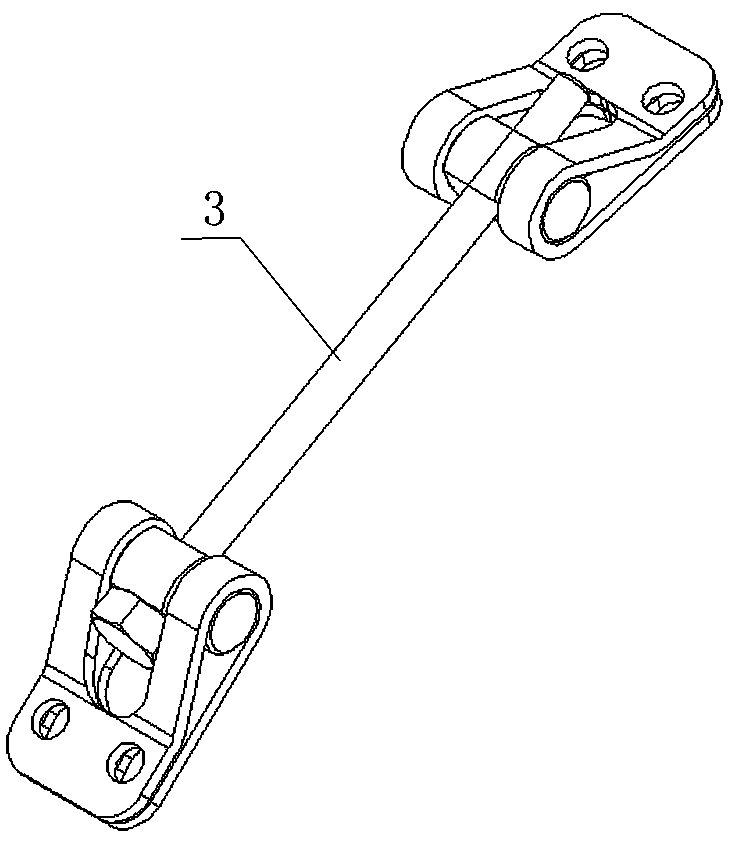

[0033] The tire blowout emergency safety device for passenger cars includes a multi-section steel belt 2 that is assembled in the groove of the rim 1, and the multi-section steel belt 2 is connected in series through a fixed locking block 5 and connected in series. The two ends of the rear steel strip are connected by an adjustment locking mechanism 3 to form an endless belt;

[0034] A plurality of anti-retraction unit assemblies 4 are arranged on the endless belt. The anti-retraction unit assembly 4 includes a fixed block 41. The fixed block 41 is fixed on the surface of the endless belt. Cooperating anti-retraction ring 42, one end of fixed block 41 is provided with waist-shaped hole 48, and is integrated with anti-retraction ring 42 by hinged structure, makes anti-retraction ring 42 can form the opening and closing by the hinge of fixed block sports relationship;

[0035] The outer side of the waist-shaped hole 48 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com