Cloth placing frame

A technology for placing racks and fabrics, which is applied in thin material processing, winding strips, transportation and packaging, etc. It can solve the problems of inconvenient operation and inability to realize height adjustment, and achieves convenient loading and unloading maintenance, simple structure and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

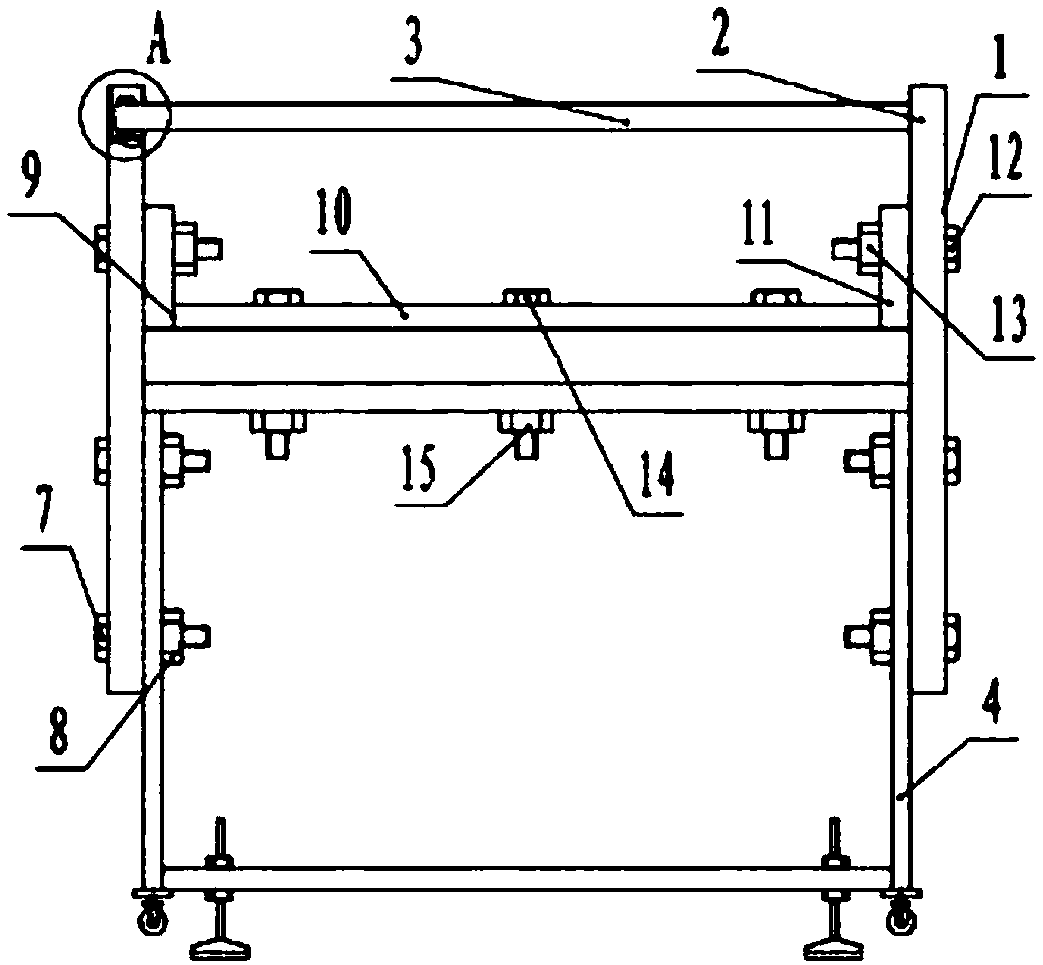

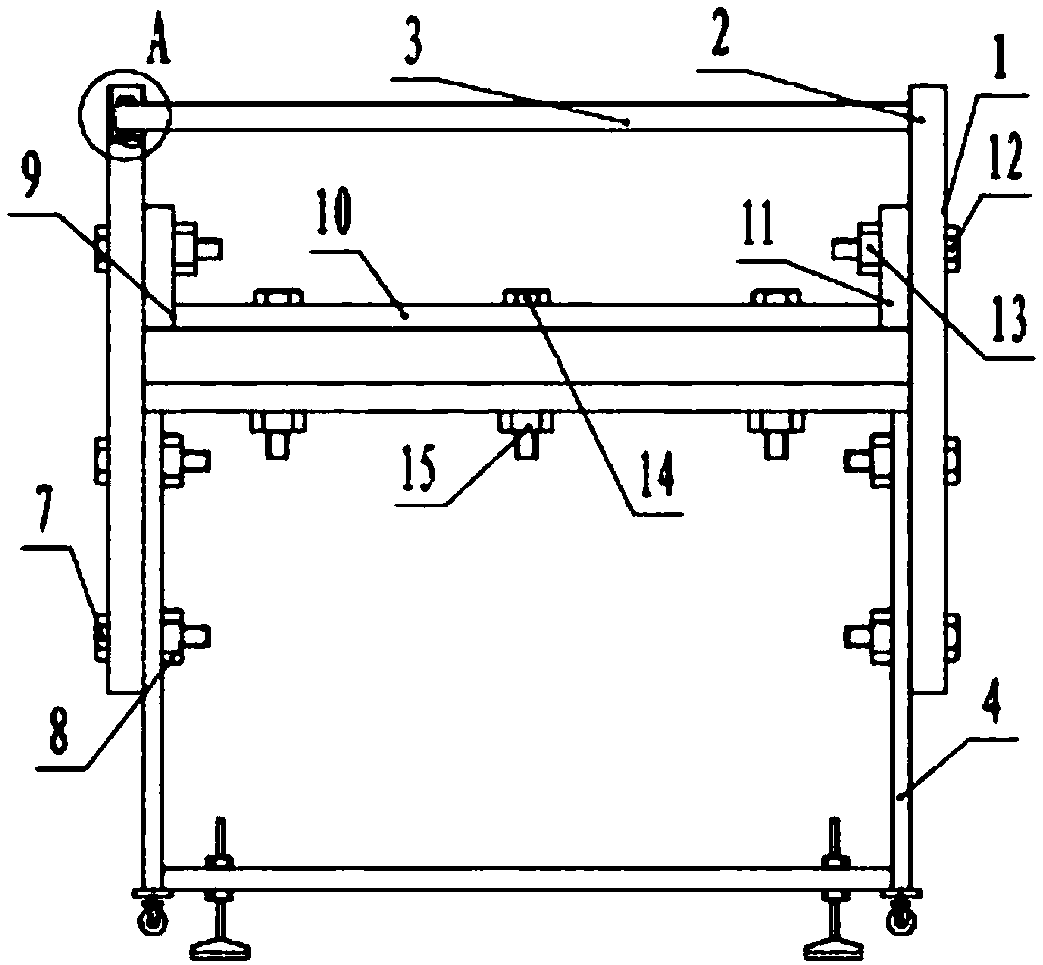

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0013] Such as figure 1 As shown, a cloth placing frame includes two vertically placed support rods 1, and the two support rods 1 are fixedly connected to the right end support leg 4 of the cloth cutting platform 2 symmetrically front and back, and placed on the top of the two support rods 1 There is a detachable rotating shaft 3 for winding cloth, and a plurality of installation adjustment holes 16 are arranged on the outside evenly distributed vertically. The rotating shaft 3 can rotate around the axis. The distance between the adjustment holes 16 is the existing two rows of screws-7 and nuts. One-half of the installation distance of 8. The two support rods are fixedly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap