Edge-twisting epicyclic wheel

A technology of star wheel and hemming, applied in textile, textile and papermaking, looms, etc., can solve the problems of different star wheel spacing, loom stoppage, affecting the production efficiency of loom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

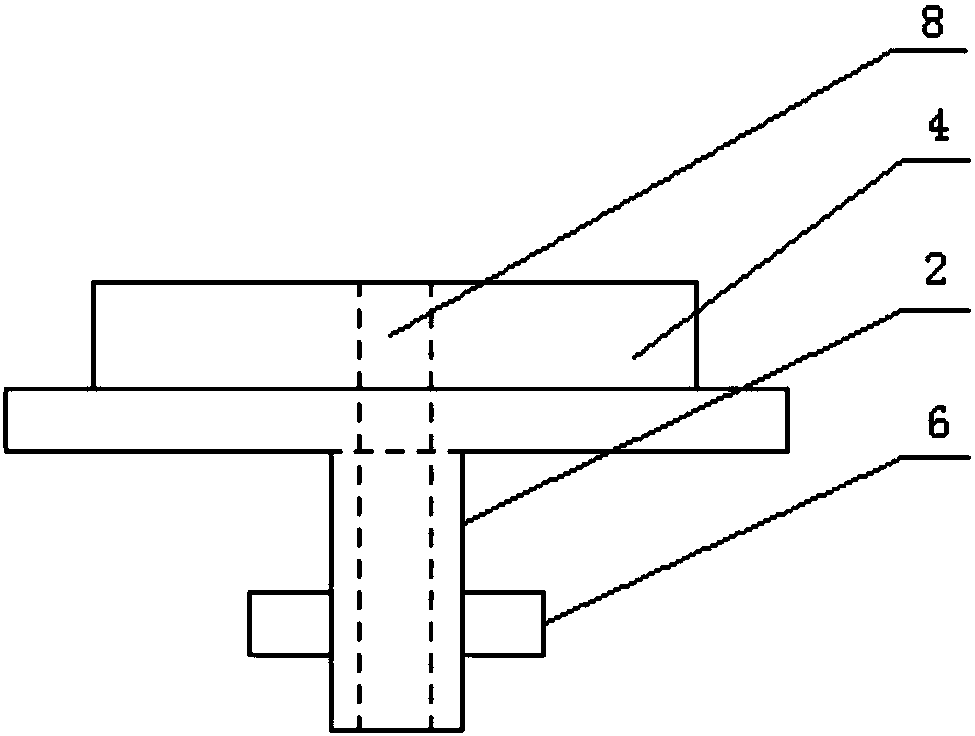

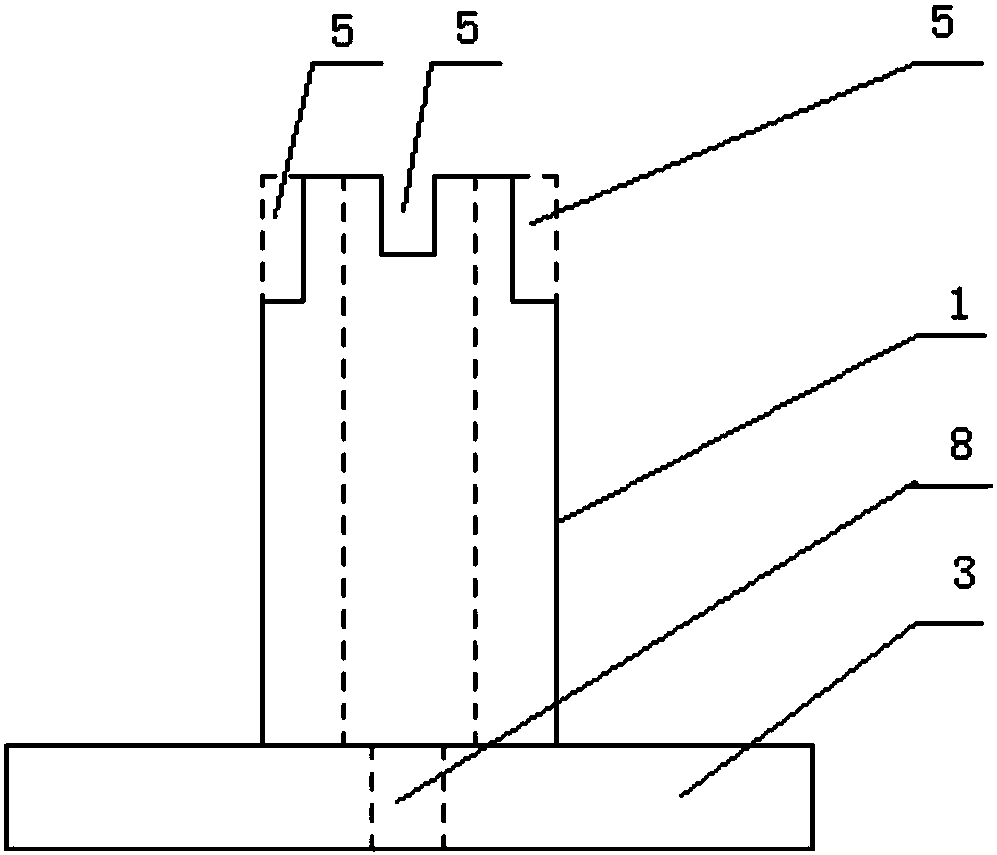

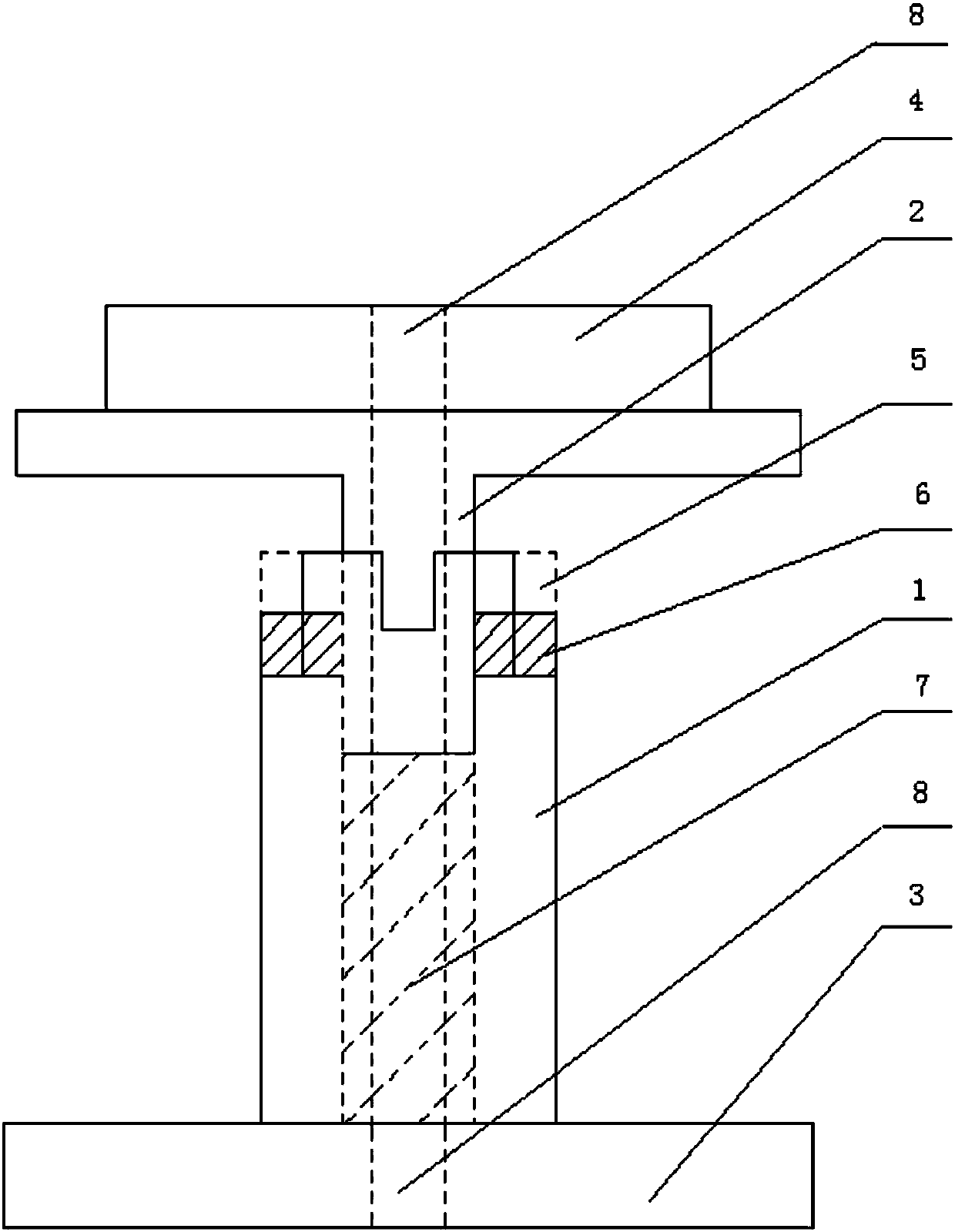

[0020] Such as Figure 1-3 As shown, the hemming planetary wheel of the present invention includes a yarn winding tube 1, an inner tube 2, a first planetary wheel 3, and a second planetary wheel 4, and the second planetary wheel is fixed at one end of the yarn winding tube 1 Wheel 4, two groups of penetrating grooves 5 are arranged symmetrically on the cylinder wall at the other end of the winding cylinder 1, and the lengths of the two groups of penetrating grooves 5 are not the same, and two retaining rods 6 are symmetrically fixed on the cylinder wall of the inner cylinder 2, and the inner cylinder 2 One end is fixed to the first planetary wheel 3, the other end is inserted into the winding bobbin 1, the retaining rod 6 is inserted into the longer through groove 5, the outer diameter of the inner cylinder 2 corresponds to the inner diameter of the winding bobbin 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com