Non-contact three-dimensional measuring system

A three-dimensional measurement and non-contact technology, applied in the field of three-dimensional measurement, can solve the problems that the three-dimensional measurement system cannot meet the measurement requirements and the three-dimensional measurement data is inaccurate, so as to improve the accuracy and solve the effect of inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

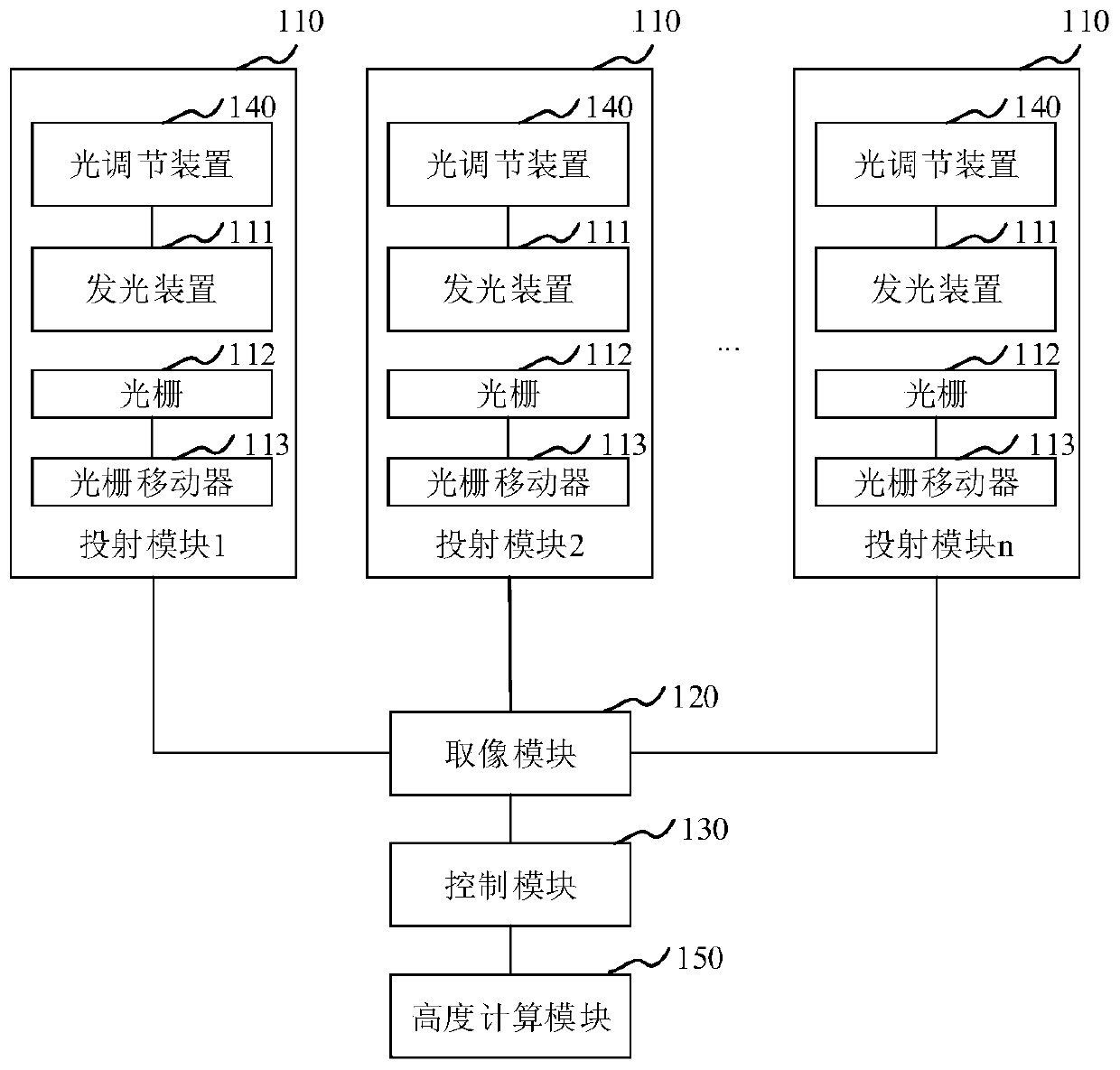

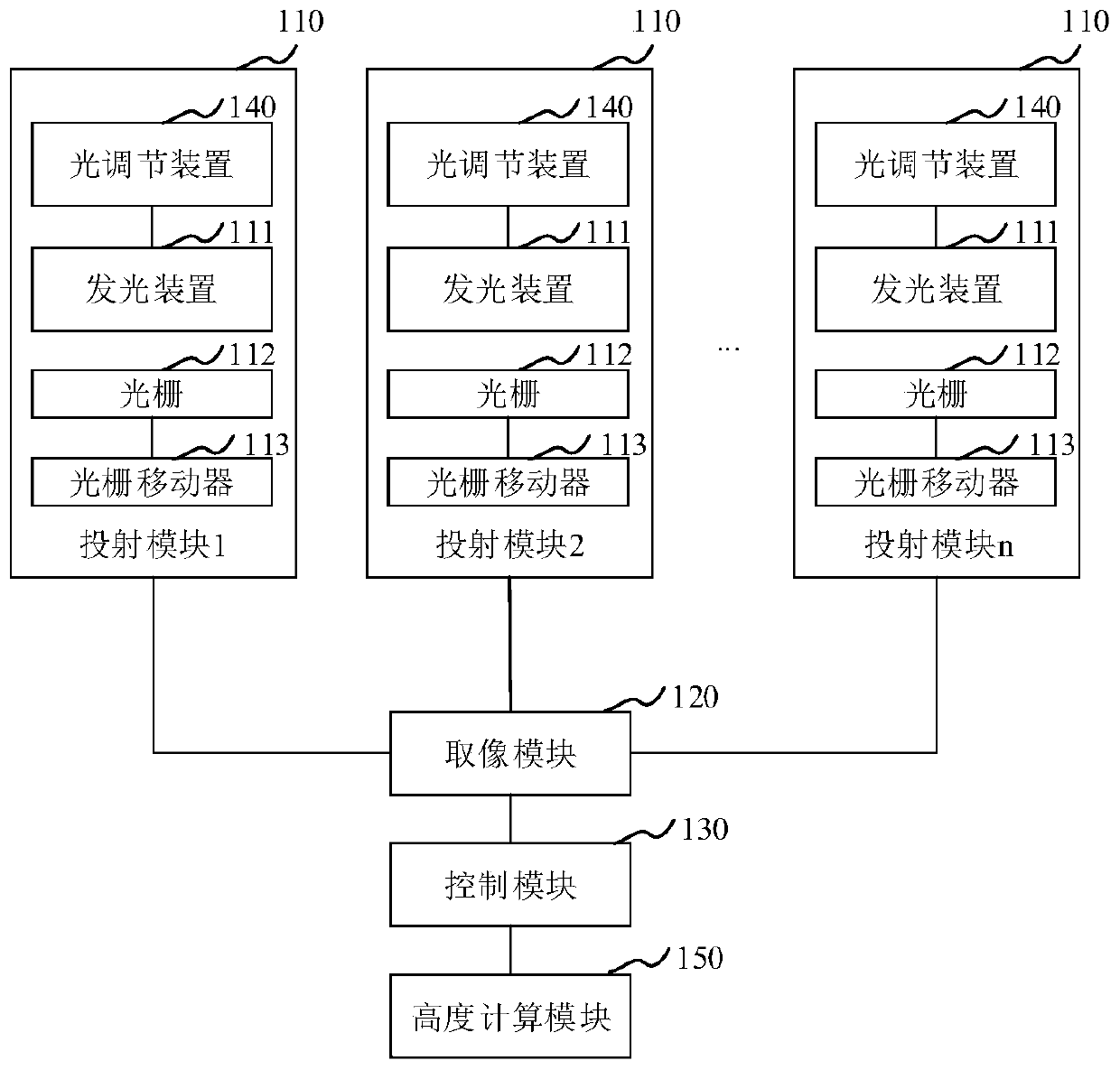

[0023] figure 1 is a schematic structural diagram of a non-contact three-dimensional measurement system provided by an embodiment of the present application, such as figure 1 As shown, the system includes at least:

[0024] n projection modules 110 irradiate striped light toward the object to be measured along the corresponding optical axis, and the incident angles of the optical axes of different projection modules relative to the measurement plane are different; n is an integer greater than or equal to 2; each projection module includes a light adjustment device 140. The light adjusting device 140 changes the phase of the fringes projected onto the object to be measure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap