A method for ultrasonic and microwave-assisted extraction of total flavonoids from passionflower seed oil and meal

A technology of passion flower seed oil and auxiliary extraction, which is applied in the direction of pharmaceutical formulations, ketone active ingredients, medical preparations containing active ingredients, etc., and can solve the problem of low flavonoid extraction content, low mass transfer driving force, and poor flavonoid concentration Too small and other problems, to achieve the effect of high flavonoid extraction content, simple extraction process, and increased extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 A kind of method that adopts ultrasonic wave, microwave double auxiliary extraction total flavonoids of passion fruit seed oil meal

[0046] (1) pulverizing: the passionflower seed is dried to constant weight at 55 DEG C, the dried passionflower seed is pulverized with a pulverizer, crosses a 0.250mm sieve, and obtains the seed powder;

[0047] (2) Degreasing: Weigh 6.0 g of seed powder and put it into a filter paper tube, add 42 mL of petroleum ether into a quartz cup, reflux at 95°C for 70 minutes to degrease, recover petroleum ether by rotary evaporation, and collect the degreased seed oil meal;

[0048](3) Ultrasonic extraction: Weigh 1.0g of the above-mentioned seed oil meal, add ethanol-water solution with a volume fraction of ethanol of 50% according to the ratio of material to liquid 1:20g / mL, set the ultrasonic power to 200w, and extract in a constant temperature water bath at 80°C for 60min , to obtain a mixture;

[0049] (4) Microwave extraction...

Embodiment 2

[0050] Embodiment 2 A kind of method that adopts ultrasonic wave, microwave double auxiliary extraction total flavonoids of passionflower seed oil meal

[0051] (1) pulverizing: the passionflower seed is dried to constant weight at 70 DEG C, the dried passionflower seed is pulverized with a pulverizer, and crosses a 0.425mm sieve to obtain the seed powder;

[0052] (2) Degreasing: Weigh 6.0 g of seed powder and put it into a filter paper tube, add 58 mL of petroleum ether into a quartz cup, reflux at 85°C for 85 minutes to degrease, recover petroleum ether by rotary evaporation, and collect the degreased seed oil meal;

[0053] (3) Ultrasonic extraction: Weigh 1.0 g of the above-mentioned seed oil meal, add an ethanol solution with an ethanol volume fraction of 90% according to a material-to-liquid ratio of 1:60 g / mL, set the ultrasonic power to 500w, and extract in a constant temperature water bath at 80°C for 10 minutes. get mixed solution;

[0054] (4) Microwave extraction...

Embodiment 3

[0055] Embodiment 3 A kind of method that adopts ultrasonic wave, microwave double auxiliary extraction total flavonoids of passionflower seed oil meal

[0056] (1) pulverizing: the passionflower seed is dried to constant weight at 60 DEG C, the dried passionflower seed oil meal is pulverized with a pulverizer, and crosses a 0.300mm sieve to obtain the seed powder;

[0057] (2) Degreasing: Weigh 6.0 g of seed powder and put it into a filter paper tube, add 50 mL of petroleum ether into a quartz cup, condense and reflux at 85°C for 70 minutes to degrease, recover petroleum ether by rotary evaporation, and collect the degreased seed oil meal;

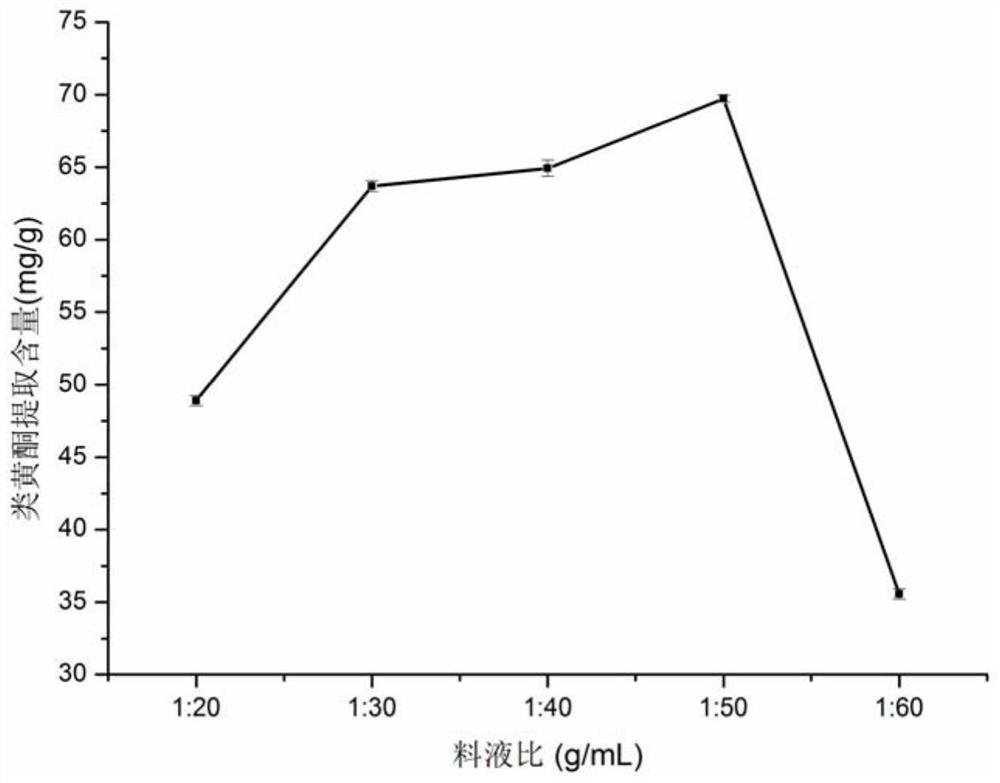

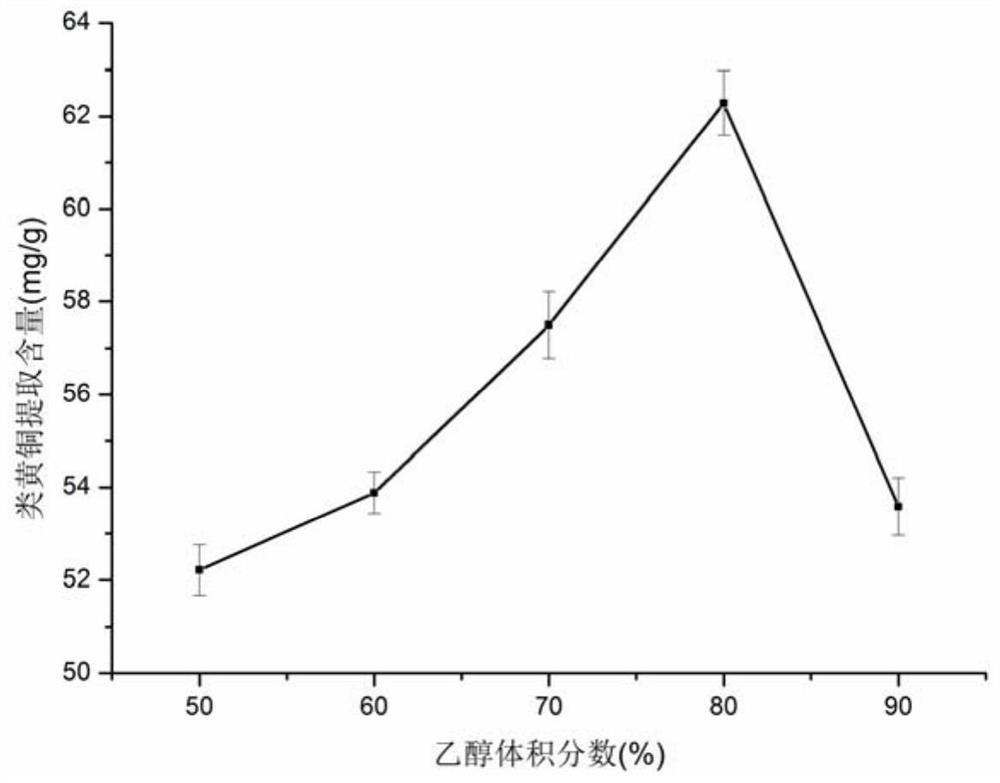

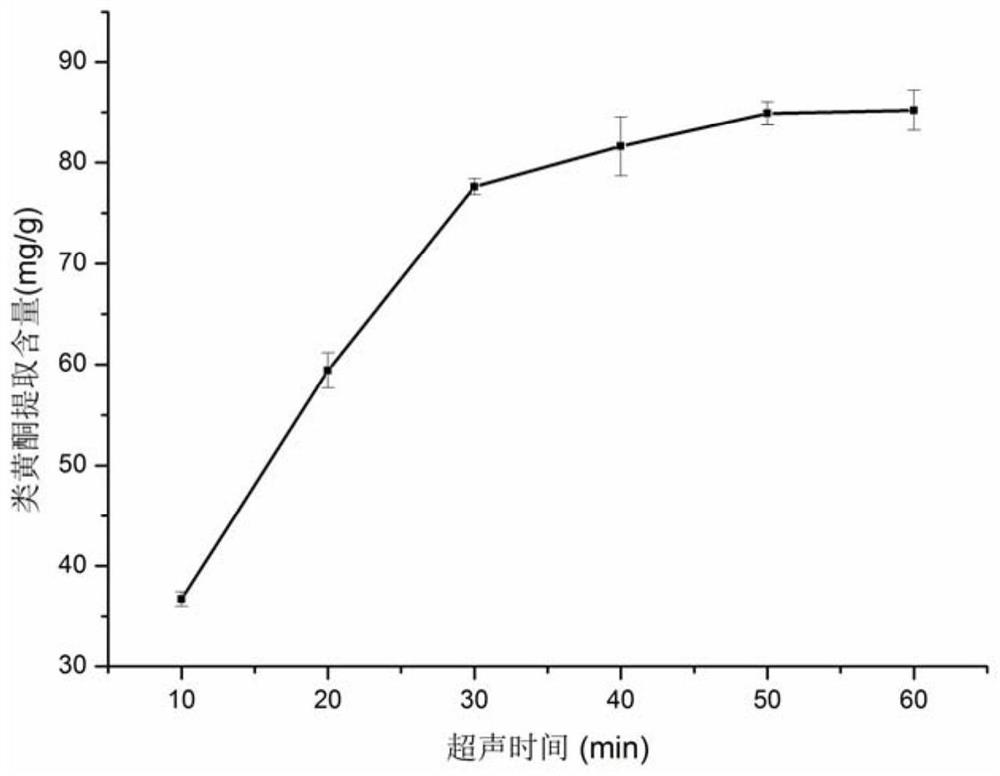

[0058] (3) Ultrasonic extraction: Weigh 1.0 g of the above-mentioned seed oil meal, add an ethanol solution with an ethanol volume fraction of 80% according to a material-to-liquid ratio of 1:50 g / mL, set the ultrasonic power to 300w, and extract in a constant temperature water bath at 80°C for 30 minutes. The number of times of ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com