Cloth bag deduster for waste gas treatment

A bag filter and waste gas treatment technology, applied in chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve problems affecting the normal production and operation of enterprises, economic losses of enterprises, etc., and achieve the effect of reducing losses and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

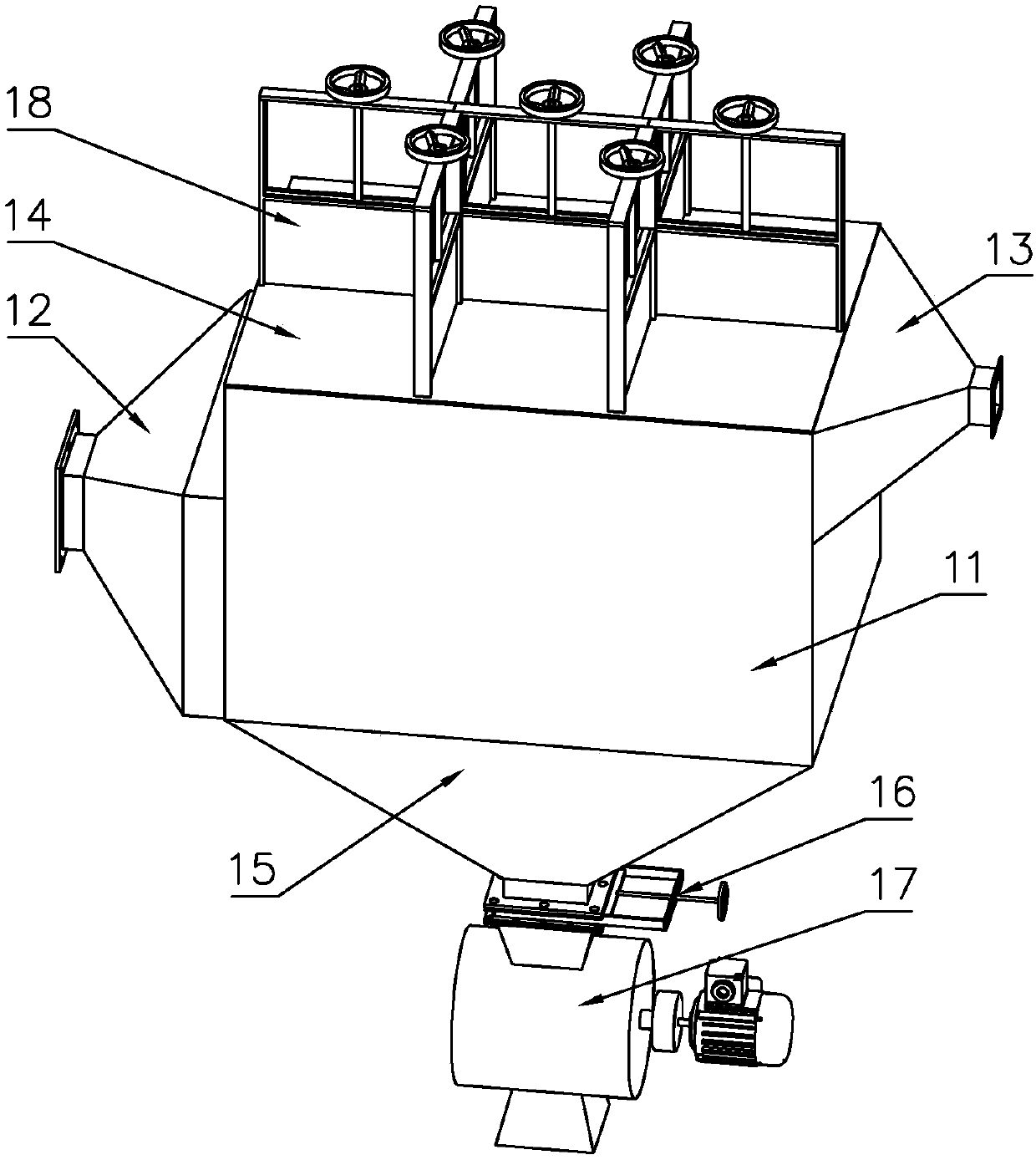

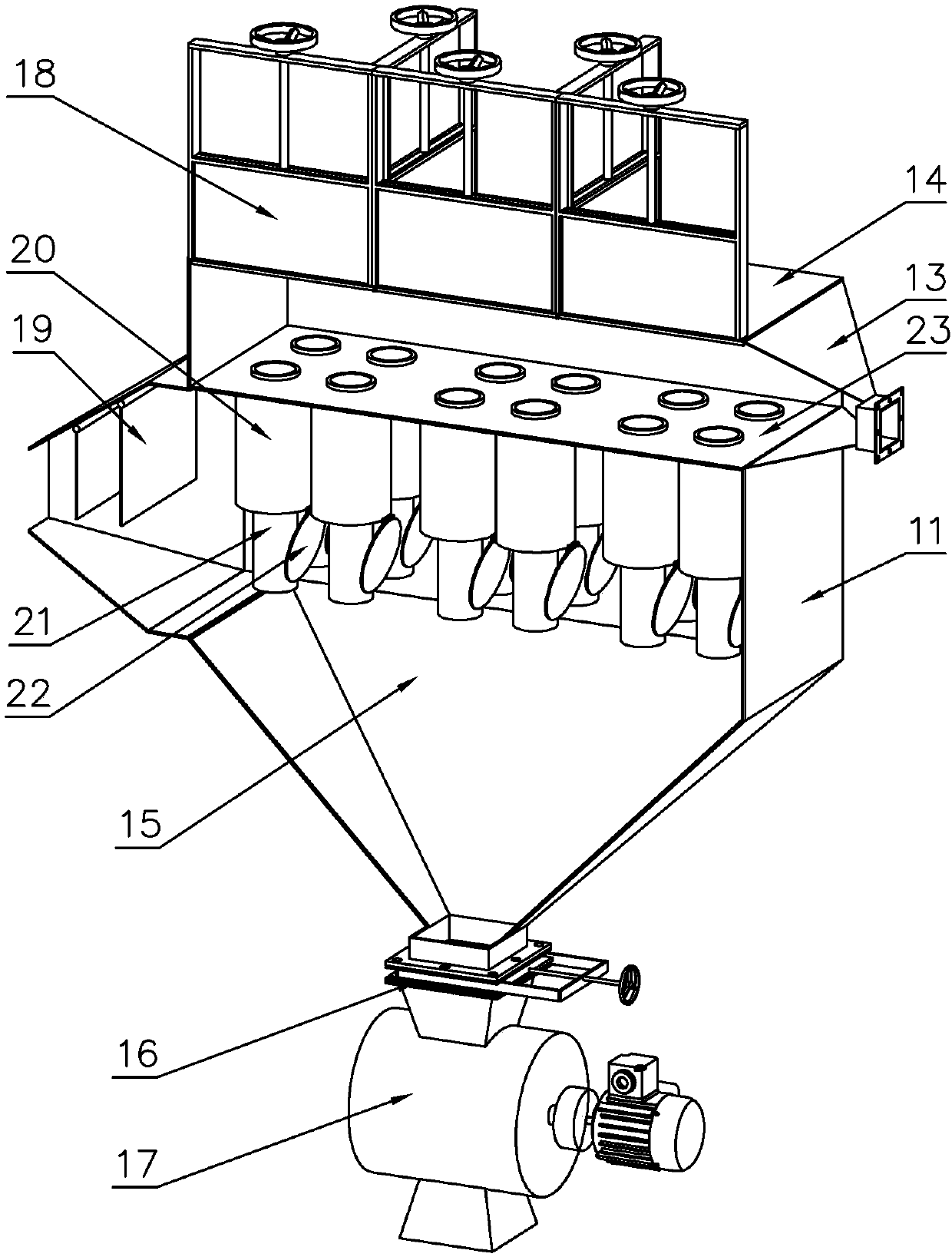

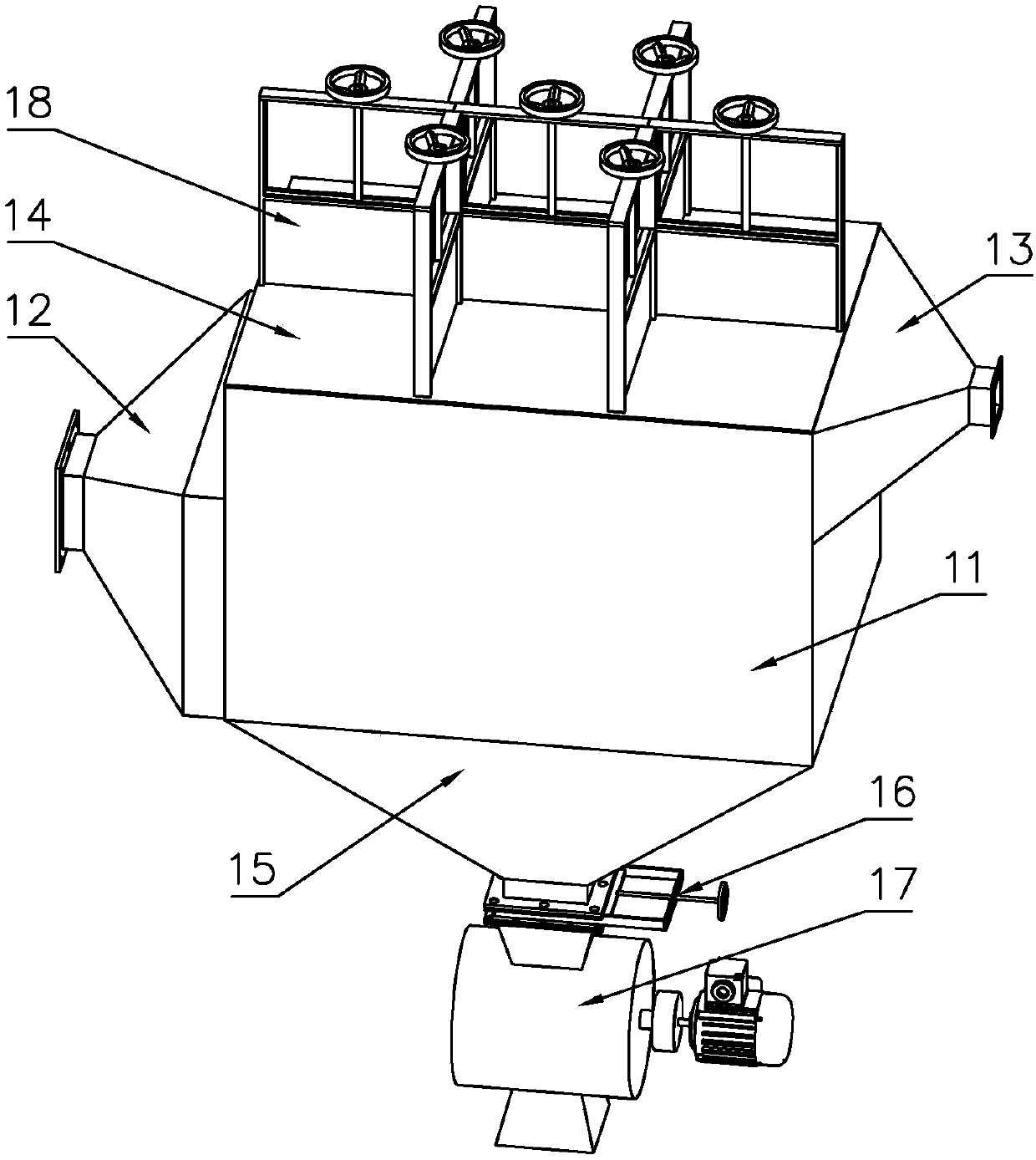

[0017] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-2 , to further specifically describe the technical solution of the present invention.

[0018] A cloth bag dust collector for waste gas treatment, comprising a housing 11, an air inlet 12, an air outlet 13, a cover plate 14, a dust collecting bucket 15, an ash unloading valve 17, a flapper valve II 18, a cloth bag 21, and a flower plate 23. There is an air inlet 12 on one side of the housing 11, the air inlet 12 is in the shape of a cone, the large end of the air inlet 12 is fixedly connected with the housing 11, the cone-shaped air inlet 12 is conducive to the uniformity of exhaust gas inside the housing 11 Distribution; the other side of the housing 11 is provided with an air outlet 13, the air outlet 13 is cone-shaped, the large end of the air outlet 13 is fixedly connected with the housing 11, and the cone-shaped air outlet 13 is conducive to dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com