Medium-speed coal mill outlet air temperature adjusting method

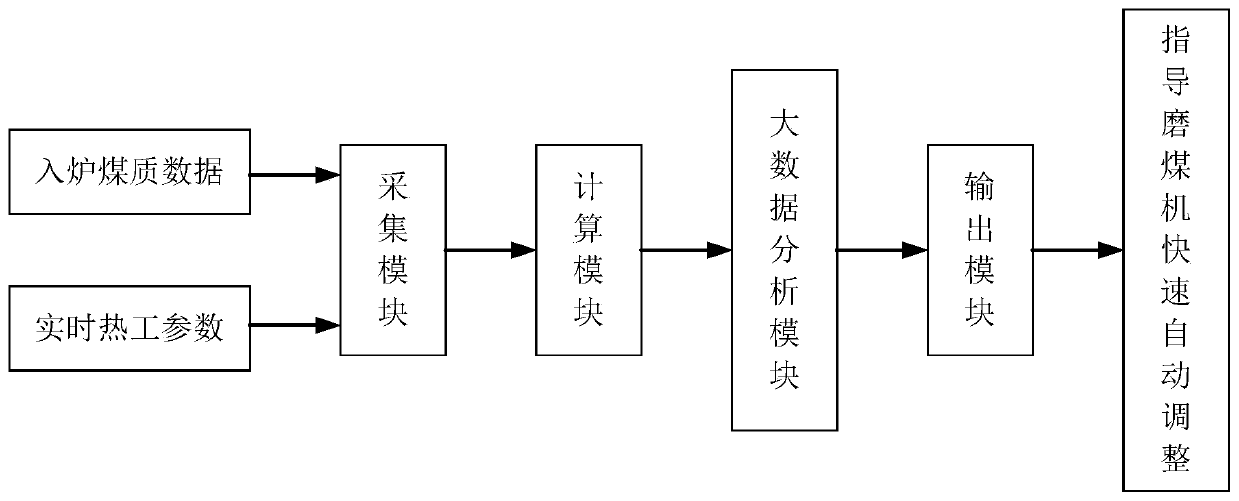

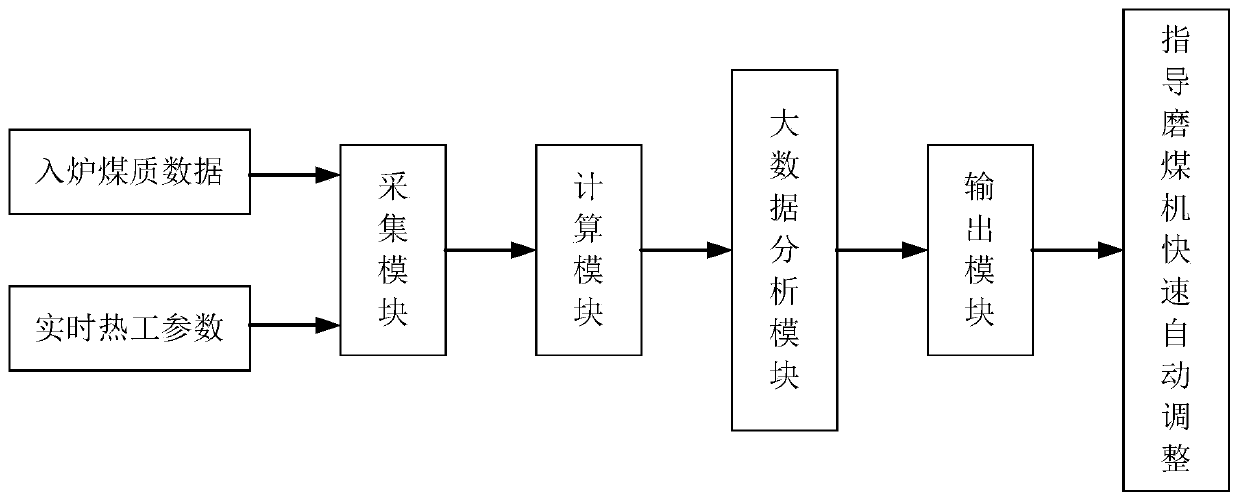

A coal mill and temperature adjustment technology, applied in grain processing, etc., can solve problems such as inconvenient operation, slow air temperature adjustment speed, and excessive air temperature adjustment, and achieve the effect of improving rapid response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

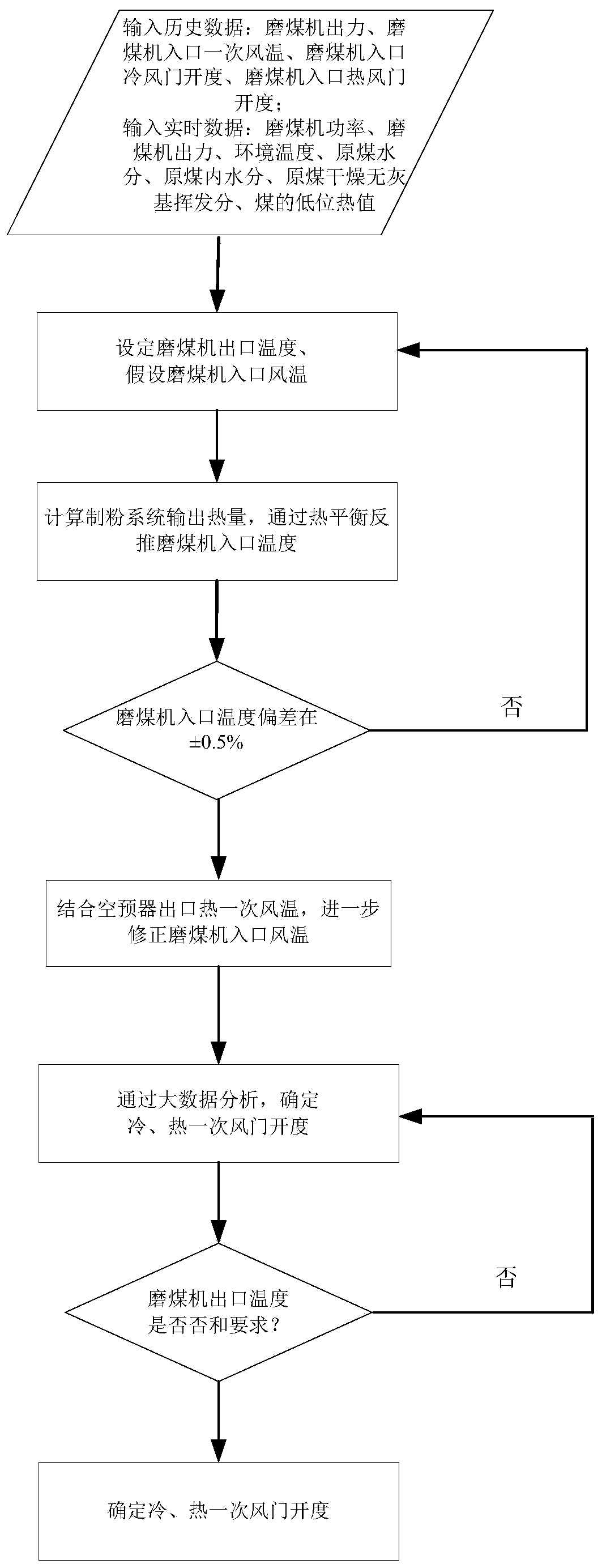

Embodiment 1

[0050] The outlet temperature setting of the coal mill is determined according to the type of coal. When the coal is dry and ash-free, the volatile V daf ≤40%, coal mill outlet temperature t M2 Controlled at 75°C, when coal-fired dry ash-free base volatile V daf When >40%, the coal mill outlet temperature t M2 It is controlled at 60-70°C, and the inlet temperature of the coal mill is set, which is calculated by heat balance.

[0051] In heat balance calculation, first determine the total input heat q of the milling system in

[0052] q in =q ag1 +q le +q s +q mac

[0053] q ag1 Physical heat of desiccant, kJ / kg; q le Physical heat leaked into the cold air, take 0, kJ / kg; q s Physical heat of sealing air, kJ / kg; q max The mechanical heat generated by the coal mill, kJ / kg.

[0054] q ag1 =C ag1 t 1 g 1

[0055] Drying dose entering the coal mill, kg / kg; Q v Primary air volume at the coal mill inlet, t / h; B M Output for coal mill, t / h; c ag1 for t 1 Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com