A protective device for a sand washing gun

A technology of protection device and blasting gun, applied in explosion generating device, used abrasive treatment device, spray gun, etc., can solve problems affecting construction quality and efficiency, operator influence, coating damage, etc., and achieve novel structure , The effect of stable installation and not easy to fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

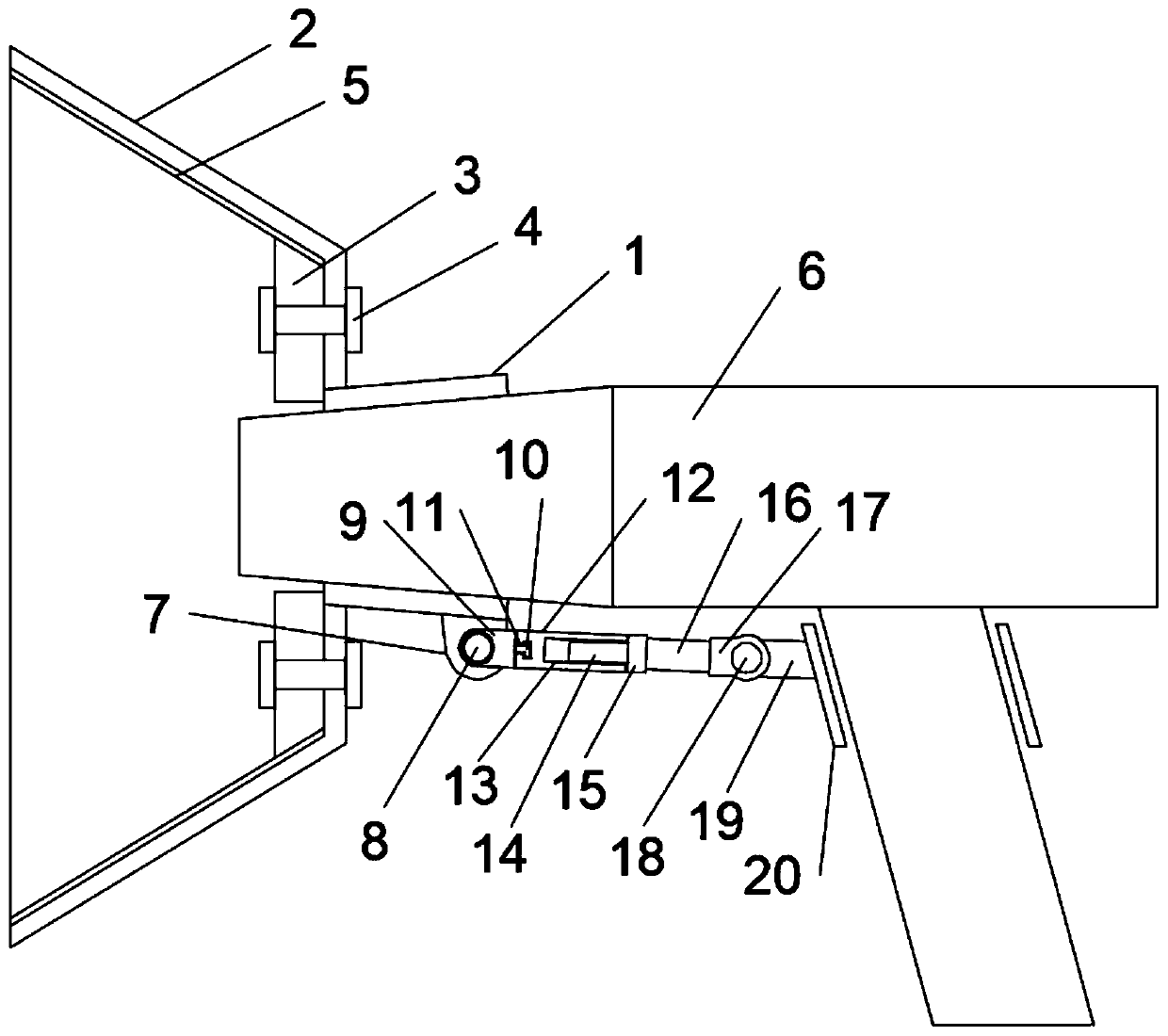

[0015] The present invention will be further described below in conjunction with accompanying drawing.

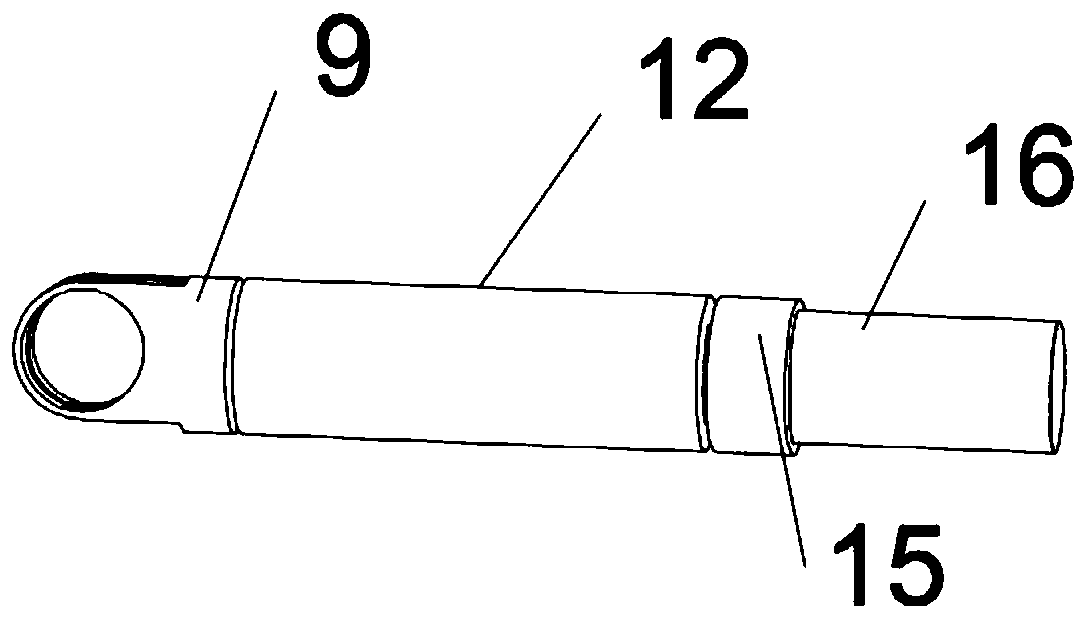

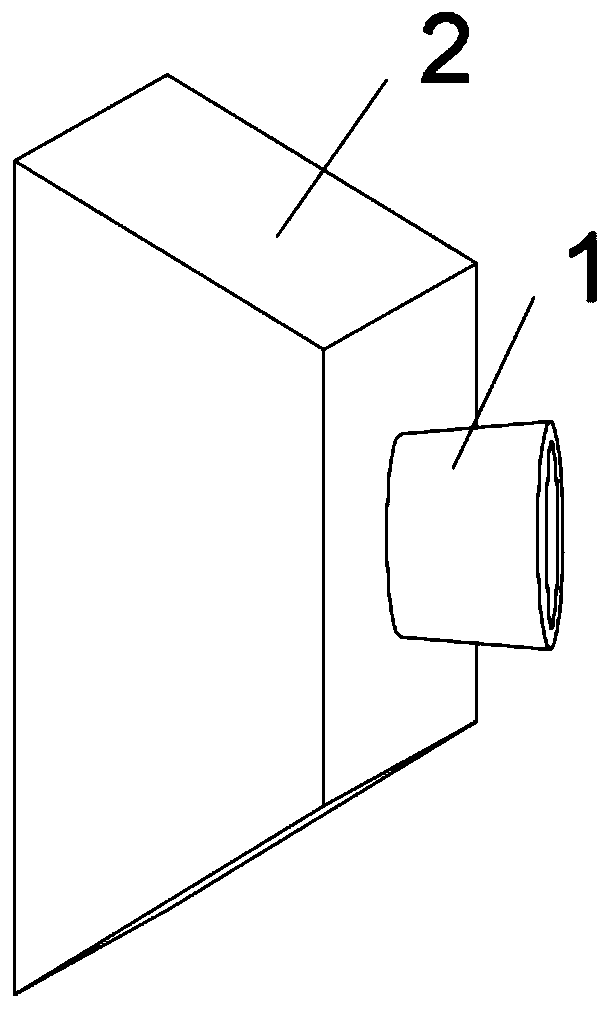

[0016] Such as Figure 1-3 The shown protective device for a sand washing gun includes a gun head cover 1, which is in the shape of a cylinder with a narrow top and a wide bottom. A transparent cover 2 is welded on the outer side of the narrow end of the gun head cover 1, and the transparent cover 2 is close to the gun head cover 1. The inner side of one end of the inner cover is connected to the inner cover connecting plate 3 through several fixing bolts 4, and the inner cover connecting plate 3 is bonded with a quartz inner cover 5. On the ejection end of the gun head body 6, the handle end of the gun head body 6 is sleeved with a handle glove 20, and the outside of the wide end of the gun head cover 1 is welded with a pull rod connector 7, and the pull rod connector 7 passes through the No. 1 hinge 8 A movable head 9 is connected.

[0017] An insert 10 is welded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com