Automatic grout distributing device and grout distributing method for the bottom of ceramic tile adobe

A technology for ceramic bricks and bottom slurry, applied in the field of ceramic tile production, can solve the problems of easy deviation of the hollow soft rubber tube, damage to the performance and concentration of the bottom slurry, uneven bottom of the tile, etc., to control the thickness and uniformity of the slurry, The effect of high bottom slurry utilization and consistent bottom slurry performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with accompanying drawing:

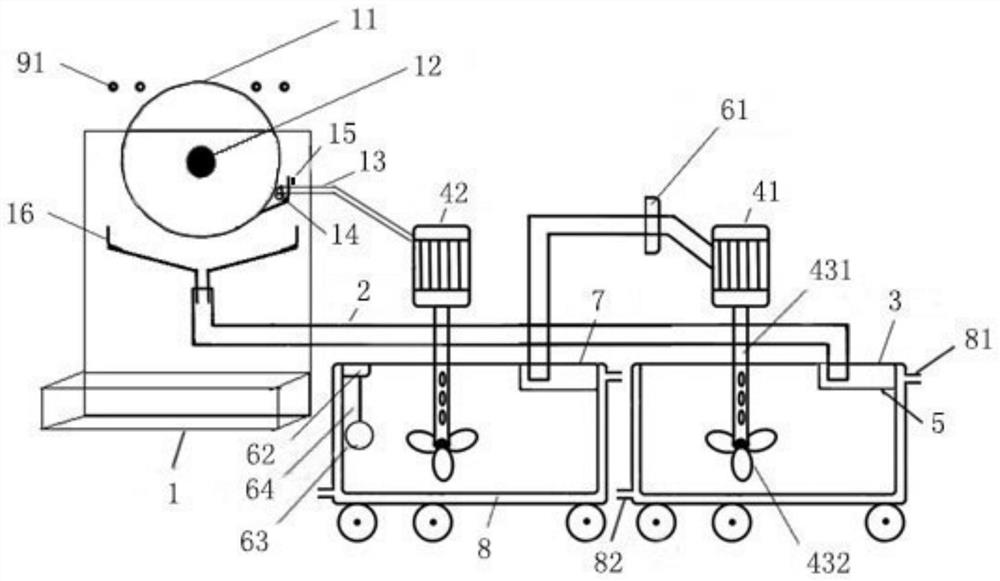

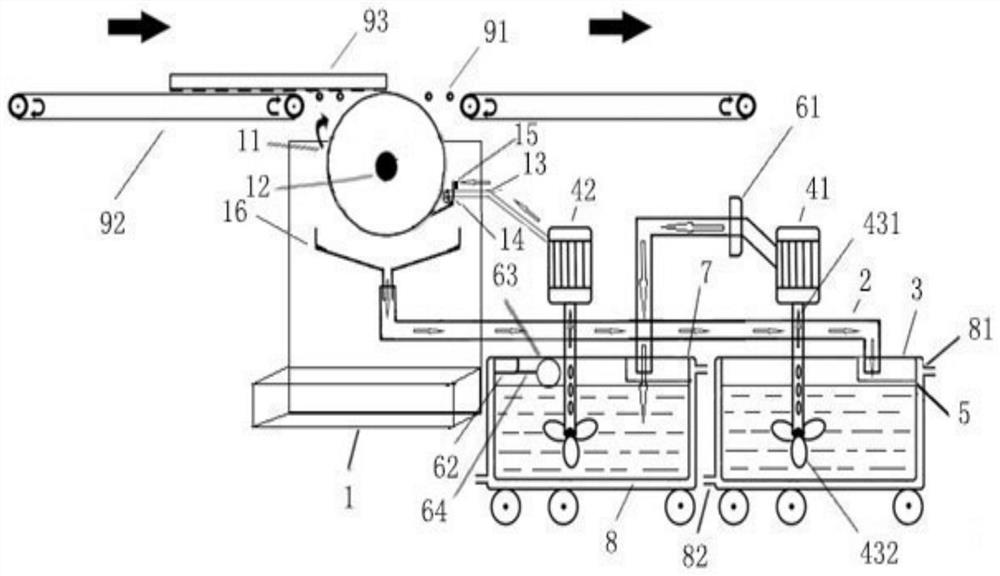

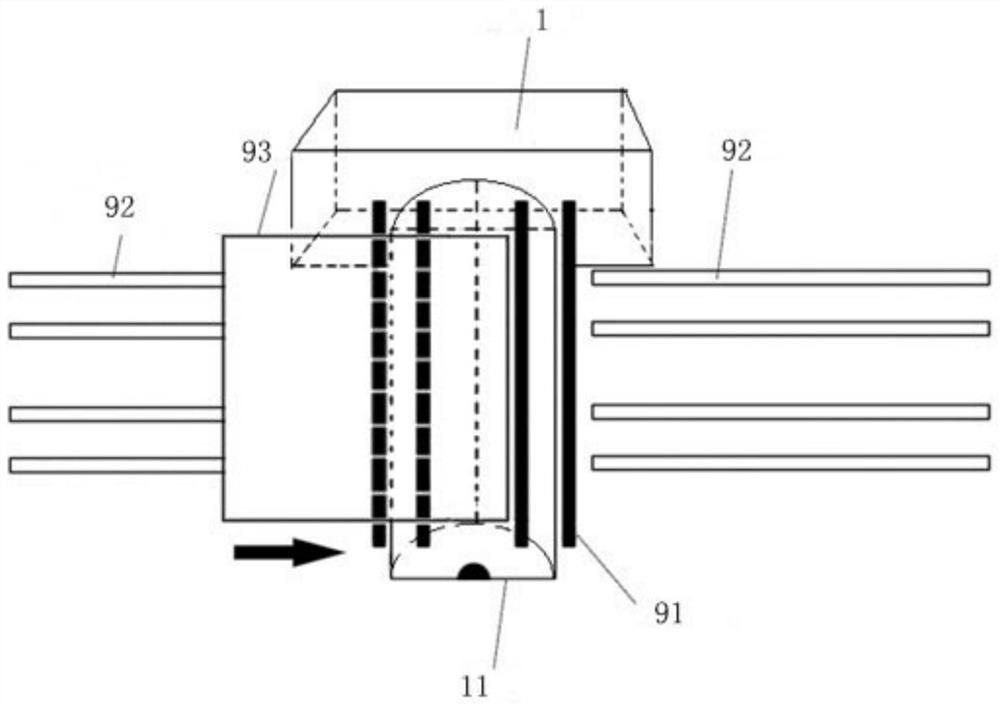

[0048] see figure 1 , image 3 As shown, the slurry distributing device is mainly composed of a transfer bottom slurry tank 3, a bottom slurry tank 7, a slurry return pipe 2, an automatic induction glazing device 71 (composed of an automatic induction valve 61, an inductor 62, and a suspension ball 63), a cooling Circulation system, rubber roller flower machine 1, rubber roller cylinder 11, support roller shaft 91, scraper 14 and primer tank 16 are composed.

[0049] The glaze of the transfer base tank 3 and the base tank 7 is made of stainless steel in the shape of a barrel. In particular, a set of cooling circulation system is installed on the outer wall of the transfer base tank 3 and base tank 7, and the temperature of the glaze slurry is controlled by cooling water circulation. Ensure the bottom slurry performance; the first bottom slurry pump 41 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com