Prefabricated box girder prestress advanced positioning device and implementation method thereof

A positioning device and prestressing technology, used in manufacturing tools, ceramic molding machines, etc., can solve the problems of low machining accuracy and slow installation speed, and achieve the effect of improving installation efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

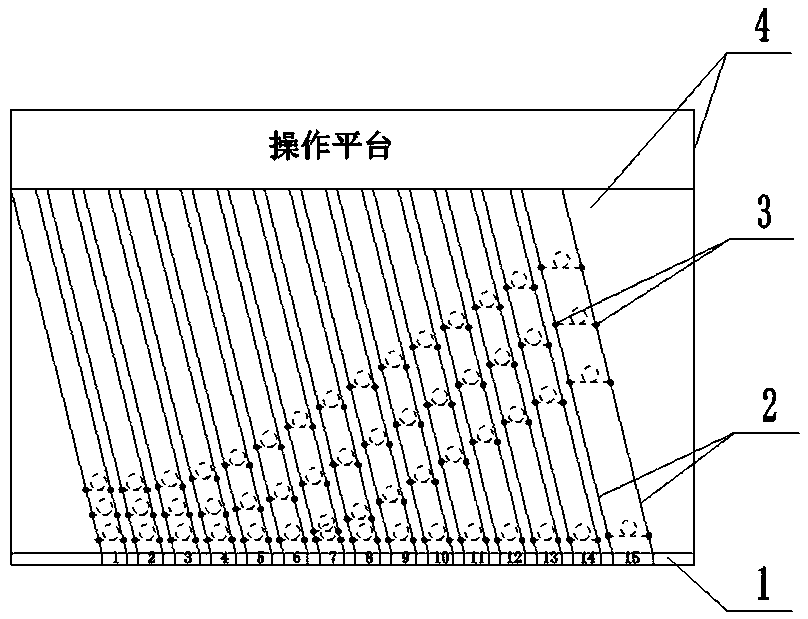

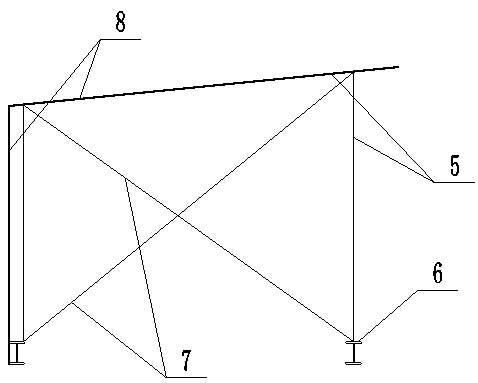

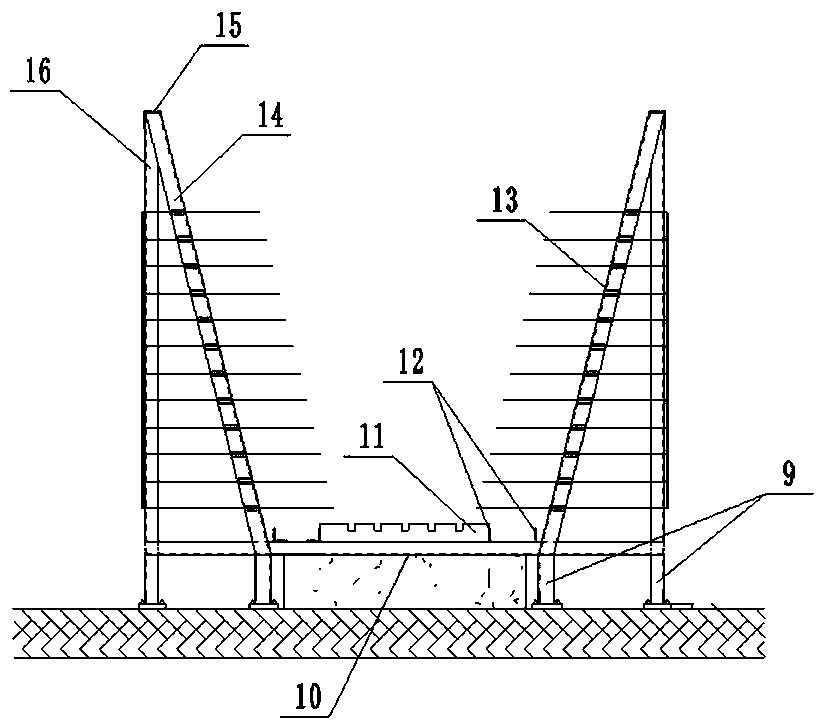

[0021] A schematic diagram of the overall structure of a prefabricated box girder prestressed advance positioning device according to the present invention, which includes a corrugated tube positioning rib welded tire frame, a web stirrup classification storage bracket and a bottom web steel bar binding tire frame.

[0022] like figure 1 As shown, it is a structural schematic diagram of the welded tire frame of the bellows positioning ribs according to the present invention. The welded tire frame of the bellows positioning ribs is composed of a stirrup positioning channel steel 1, a stirrup positioning marking line 2, a bellows positioning rib 3 and a steel plate tire frame The base 4 is composed of the steel plate frame base 4, which is made of a steel plate with a length of 3000 mm, a width of 2000 mm, and a thickness of 10 mm, and is arranged on the stirrup positioning channel steel 1. Stirrup positioning mark line 2.

[0023] like figure 2 As shown, it is a structural s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com