A cloth device for wine production

A technology of a cloth device and a feeding tray, which is applied in the field of winemaking, can solve problems such as uneven cloth, and achieve the effect of high cloth efficiency and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

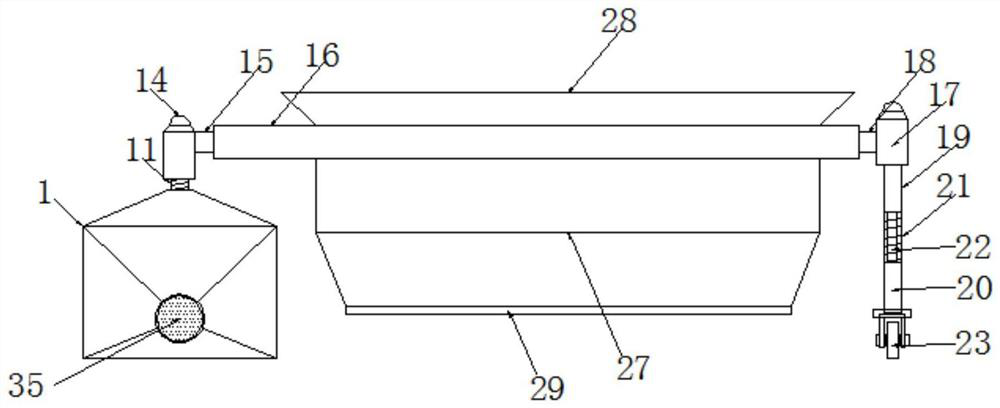

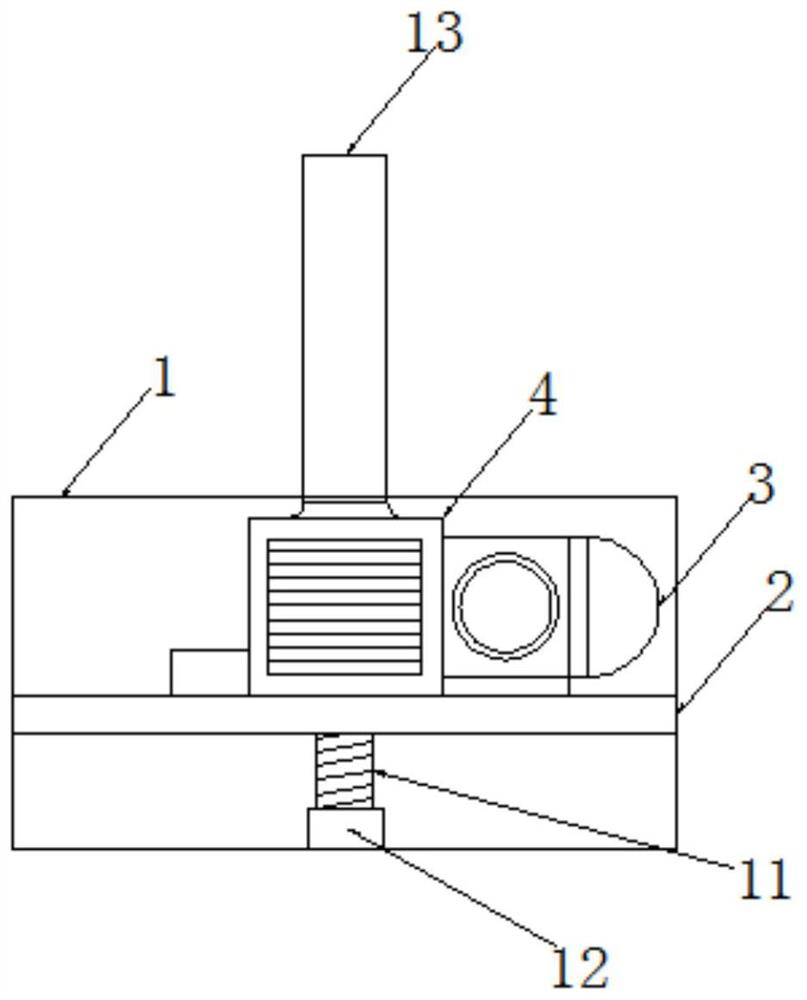

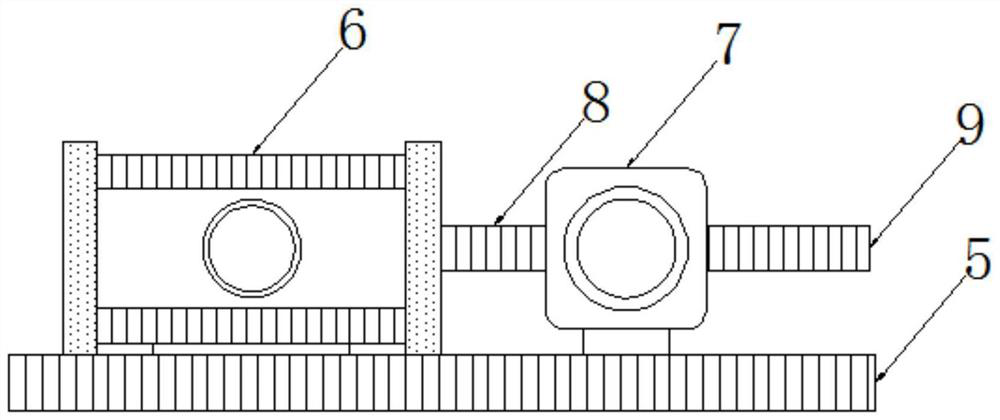

[0022] Such as Figure 1-7 As shown, this specific embodiment adopts the following technical solutions: a cloth distribution device for brewing production, including a power box 1, the interior of the power box 1 is hollow, and a substrate 2 is fixedly installed in the inner cavity of the power box 1. A motor housing 3 and a worm gear housing 4 are fixedly installed on the upper end surface of the base plate 2, and the inside of the motor housing 3 and the worm gear housing 4 are both hollow, and a motor mounting plate 5 is fixedly installed on the bottom plate of the inner cavity of the motor housing 3. A motor 6 and a shaft coupling 7 are fixedly installed on the upper end surface of the motor mounting plate 5, and the output end of the motor 6 is fixedly connected with the input end of the shaft coupling 7 through a drive shaft 8, and the output end of the shaft coupling 7 is fixedly connected with Drive shaft 9, worm wheel 10 is installed in rotation inside the worm wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com