reforming corrosion inhibitor

A technology of corrosion inhibitor and slow release part, applied in the field of reforming corrosion inhibitor, can solve the problems of insensitive monitoring, corrosion of reforming device, etc., and achieve the effect of shortening filling frequency, good corrosion and inhibiting corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

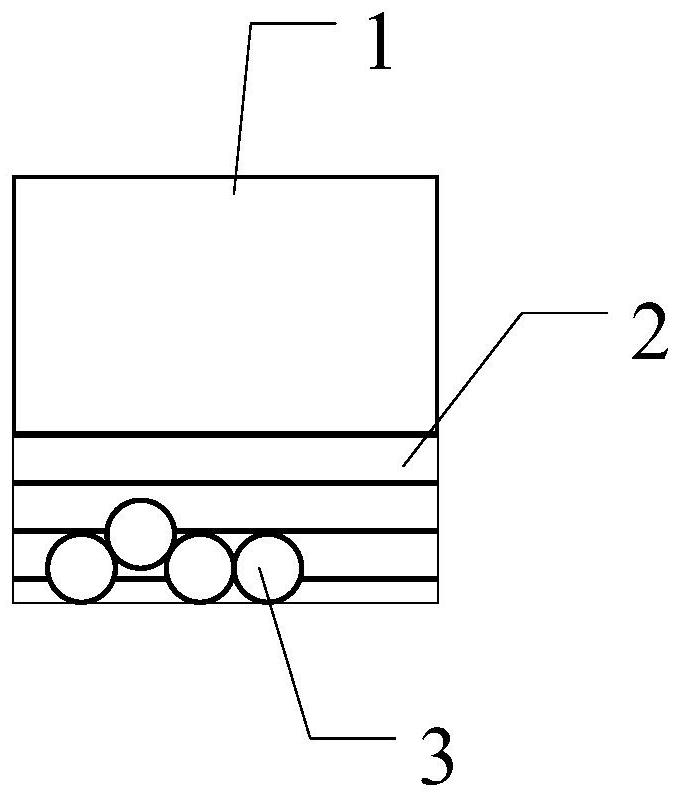

[0029] A closed metal casing is processed by welding, and an injection hole is reserved on the metal casing. The metal particles are filled into the metal shell, and then the second liquid component is injected into the metal shell. Use a metal stopper of the same material to insert into the injection hole, and make sure that the metal stopper is firmly on the injection hole.

[0030] Both the first liquid component and the second liquid component are mixed by 5 parts of imidazoline derivatives, 80 parts of oleic acid aminoamide, 2 parts of butyl phosphate, and 2 parts of dodecyl primary amine. The product is 1-hydroxyethyl-2-oleyl imidazoline. The mass ratio of the first liquid part to the second liquid part contained in the entire slow-release part is 1:1.

[0031] The corrosion inhibition effect of the corrosion inhibitor was tested by weight loss method. Add the reforming slow-release agent to the oil product evaluation system of the reforming unit, the addition amount ...

Embodiment 2

[0033] A closed metal casing is processed by welding, and an injection hole is reserved on the metal casing. The metal particles are filled into the metal shell, and then the second liquid component is injected into the metal shell. Use a metal stopper of the same material to insert into the injection hole, and make sure that the metal stopper is firmly on the injection hole.

[0034]Both the first liquid component and the second liquid component consist of 10 parts of imidazoline derivatives, 50 parts of oleic acid aminoamide, 2 parts of butyl phosphate, 2 parts of dodecyl primary amine, and 1 part of imidazoline derivatives. -Hydroxyethyl-2-oleyl imidazoline. The mass ratio of the first liquid part to the second liquid part contained in the entire slow-release part is 1:1.

[0035] The corrosion inhibition effect of the corrosion inhibitor was tested by weight loss method. Add the reforming slow-release agent to the oil product evaluation system of the reforming unit, the...

Embodiment 3

[0037] A closed metal casing is processed by welding, and an injection hole is reserved on the metal casing. The metal particles are filled into the metal shell, and then the second liquid component is injected into the metal shell. Use a metal stopper of the same material to insert into the injection hole, and make sure that the metal stopper is firmly on the injection hole.

[0038] Both the first liquid component and the second liquid component are mixed by 10 parts of imidazoline derivatives, 80 parts of oleic acid aminoamide, 1 part of butyl phosphate, and 2 parts of dodecyl primary amine. The product is 1-hydroxyethyl-2-oleyl imidazoline. The mass ratio of the first liquid part to the second liquid part contained in the entire slow-release part is 1:1.

[0039] The corrosion inhibition effect of the corrosion inhibitor was tested by the weight loss method, and steel sheets were used as coupons. Add the reforming slow-release agent to the oil product evaluation system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com