Nano antibacterial anticorrosion hydrosol coating composition

A coating composition, anti-bacterial and anti-corrosion technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as inability to meet anti-corrosion requirements, and achieve excellent anti-corrosion ability and good anti-bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment relates to a nano antibacterial anticorrosion hydrosol coating composition, and its composition and dosage are as follows in Table 1:

[0059] Table 1

[0060]

[0061]

[0062] Remark: 1 Huifu Silicon Material Co., Ltd. nano-silica sol, the content of elemental silicon is 5%, the particle size D50 is 500nm,

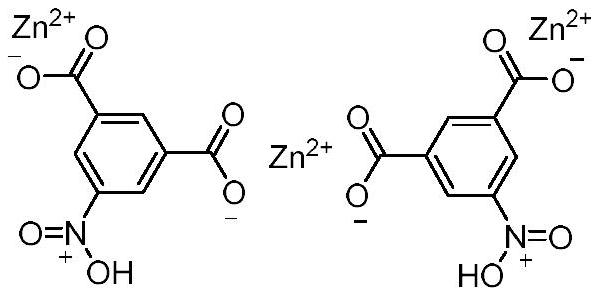

[0063] 2 Nitro m-xylene zinc purchased from Bailingwei Company, particle size D50 is 5um,

[0064] 3 The flaky metal zinc powder of Aika company, the particle size D50 is 13um,

[0065] 4 Aika's flake metal aluminum powder, the particle size D50 is 15um,

[0066] 5 The zinc phosphate powder of Haibo Chemical has a particle size D50 of 6um.

[0067] The performance test results are shown in Table 2:

[0068] Table 2

[0069] project Remark Composition 1 Composition 2 Composition 3 baking temperature 100℃ 40min 40min 40min Dry film thickness Dry film thickness meter test 7-10μm 7-10μm 7-10μm ...

Embodiment 2

[0071] This embodiment relates to a nano antibacterial anticorrosion hydrosol coating composition, and its composition and dosage are as follows in Table 3:

[0072] table 3

[0073]

[0074]

[0075] The performance test results are shown in Table 4:

[0076] Table 4

[0077] project Remark Composition 4 Composition 5 Composition 6 baking temperature 100℃ 40min 40min 40min Dry film thickness Dry film thickness meter test 5-7μm 5-7μm 5-7μm Bag adhesion GB / T9286-1998 level 0 level 0 level 0 Antibacterial ability How long does it take to grow bacteria after storage >12 months >12 months >12 months Neutral salt spray test GB / T1771-2007 1416h 1080h 1104h

Embodiment 3

[0079] This embodiment relates to a nano antibacterial anticorrosion hydrosol coating composition, and its composition and dosage are as follows in Table 5:

[0080] table 5

[0081]

[0082]

[0083] The test results are shown in Table 6

[0084] Table 6

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com