Design and construction method of large-segment hoisting self-anchorage cable suspension bridge with hinges between segments

A self-anchored suspension bridge and construction method technology, applied in the direction of suspension bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increased jacking amount and insufficient jack stroke, and achieve the effect of improving competitiveness and concise design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

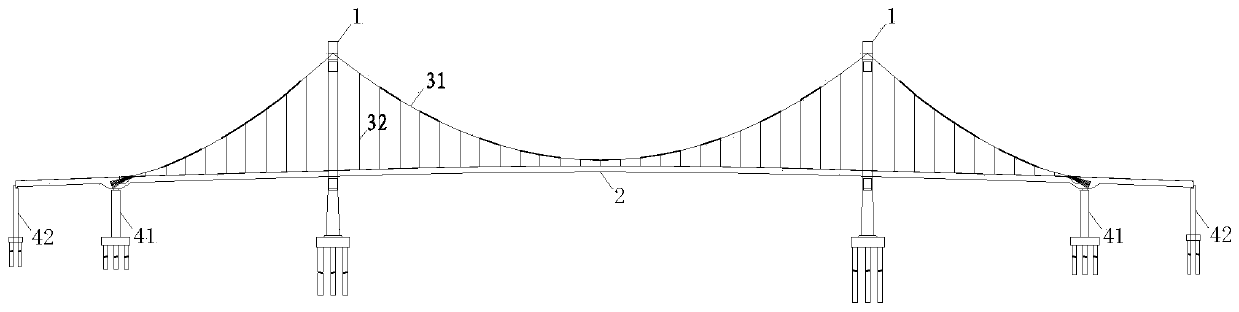

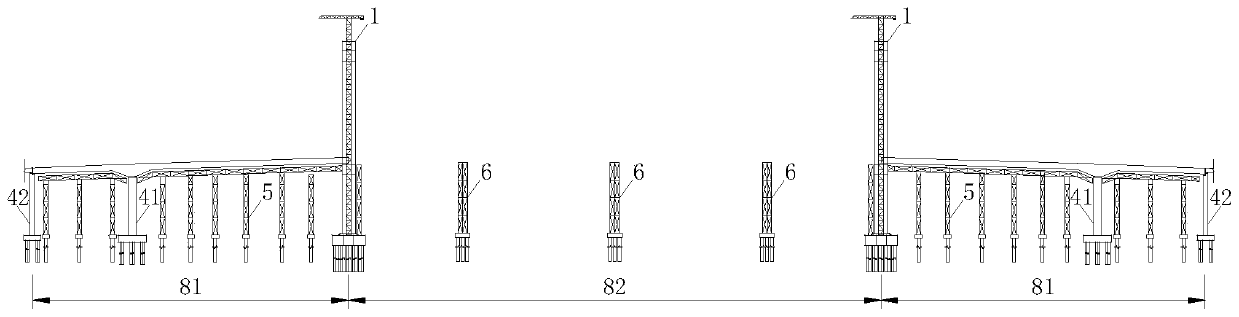

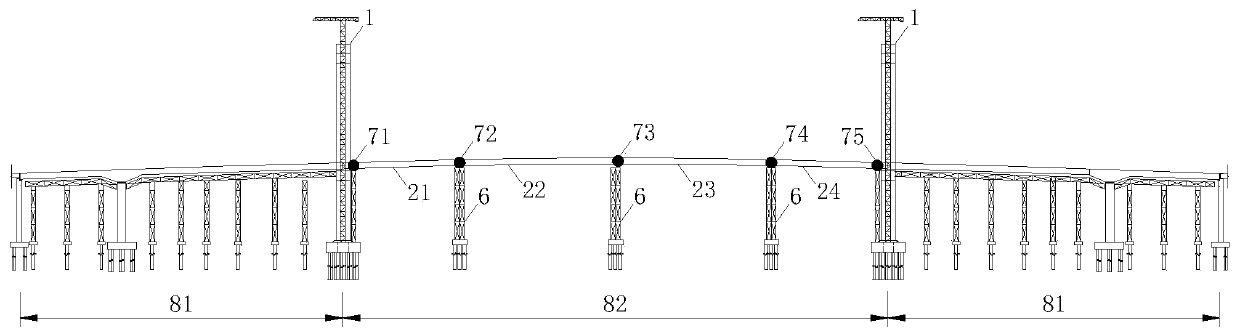

[0039] figure 1 It is a reasonable completed state of a two-tower five-span self-anchored suspension bridge, which specifies a series of states of each component after construction, such as: the internal force of the boom 32, the alignment of the main cable 31, and the alignment of the main girder 2 Wait. According to the theory of unstressed state, for a self-anchored suspension bridge, as long as the unstressed state of each component is determined, a reasonable bridge state can be obtained; the unstressed state of each component mainly includes: the unstressed cable length of the cable suspension system, the main girder 2, the initial elevation of main tower 1, etc. For the cable crane system, since it is only affected by the axial force, its unstres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com