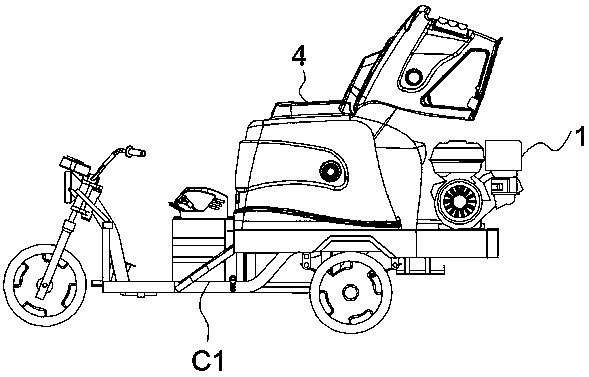

Electric three-wheel high-pressure washing vehicle with long-distance continuation of journey

A high-pressure flushing and electric three-wheel technology, which is applied to electric vehicles, electric vehicle charging technology, motor vehicles, etc., can solve the problems of short cruising range and small battery pack capacity, and achieve low cost, low cost, and easy operation. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

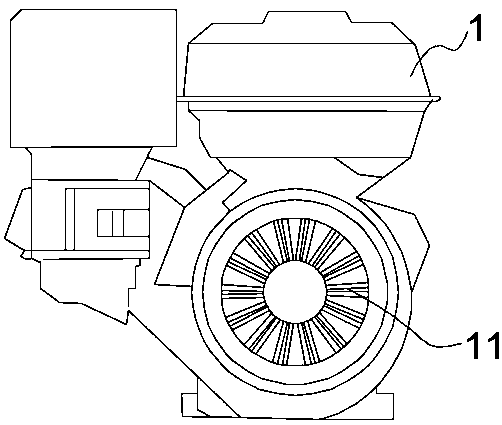

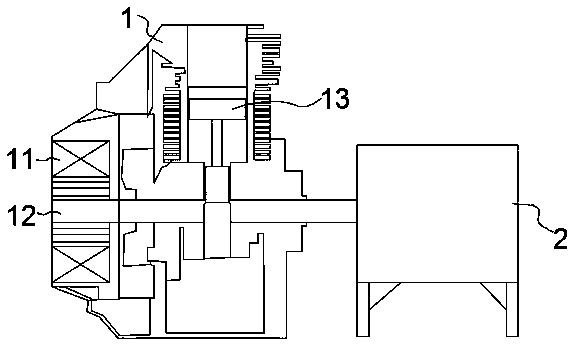

[0048] like Figure 5 , which shows another connection method of the connection structure of the long-range endurance electric three-wheel high-pressure washing vehicle, which is basically the same as the first embodiment, the difference is that the generator is connected to the power supply and also connected to the tricycle motor. The characteristics of this connection method are The generator can not only charge the power supply, but also directly drive the motor of the tricycle to run, and then drive. The first control switch a and the second control switch b are set on the corresponding circuit. Flushing can be realized by using this connection method instead of consuming the power in the power supply 5, and controlling the flow direction through the first control switch a and the second control switch b, usually the first control switch a and the second control switch b Only one can be turned on, because the gasoline engine usually cannot operate the water pump, charge t...

Embodiment 3

[0050] like Image 6 , which shows another connection method of the connection structure of the long-range endurance electric three-wheel high-pressure washing vehicle, which is basically the same as the first embodiment, the difference is that the generator is not connected to the power supply, but directly connected to the motor of the tricycle. The feature is that if the power supply is out of electricity, the tricycle cannot be driven. At this time, the gasoline engine is started, and the gasoline engine 1 drives the generator 11 to generate electricity. After the current passes through the controller, the tricycle motor is driven to run, and then the tricycle is driven. This can effectively increase the battery life.

Embodiment 4

[0052] like Figure 7 , which shows another connection method of the connection structure of the long-range endurance electric three-wheel high-pressure washing vehicle, which is basically the same as the third embodiment. It saves the cost of the vehicle, but the disadvantage is that the gasoline engine is relatively activated when driving, so it will cause unnecessary noise, and it mainly consumes energy gasoline, making it a fuel-consuming electric vehicle.

[0053] like Figure 8 , which is a common connection method, the power supply is connected to the tricycle motor, and the washing system is independent. The cruising range of the tricycle is determined by the power supply, so its cruising range is usually limited. If the capacity of the power supply is made large, the cost is relatively high.

[0054] The purpose of setting relay K1 and relay K2 is to achieve effective control. At the same time, relay K2 is a high-current relay, and relay K1 is a small-current relay, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com