Environment-friendly fabricated energy-saving plate wall system

A prefabricated, panel wall technology, applied to walls, building components, buildings, etc., can solve the problems of poor heat insulation effect, inconvenient disassembly, insufficient energy saving, etc., and achieve the effect of preventing expansion, compact structure, and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

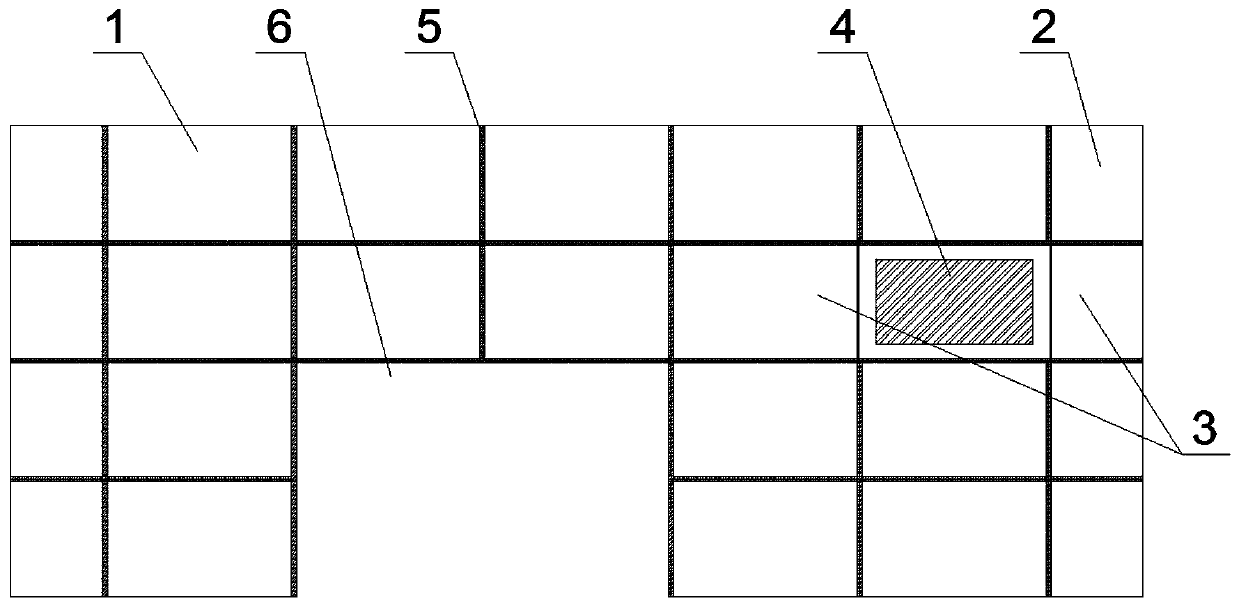

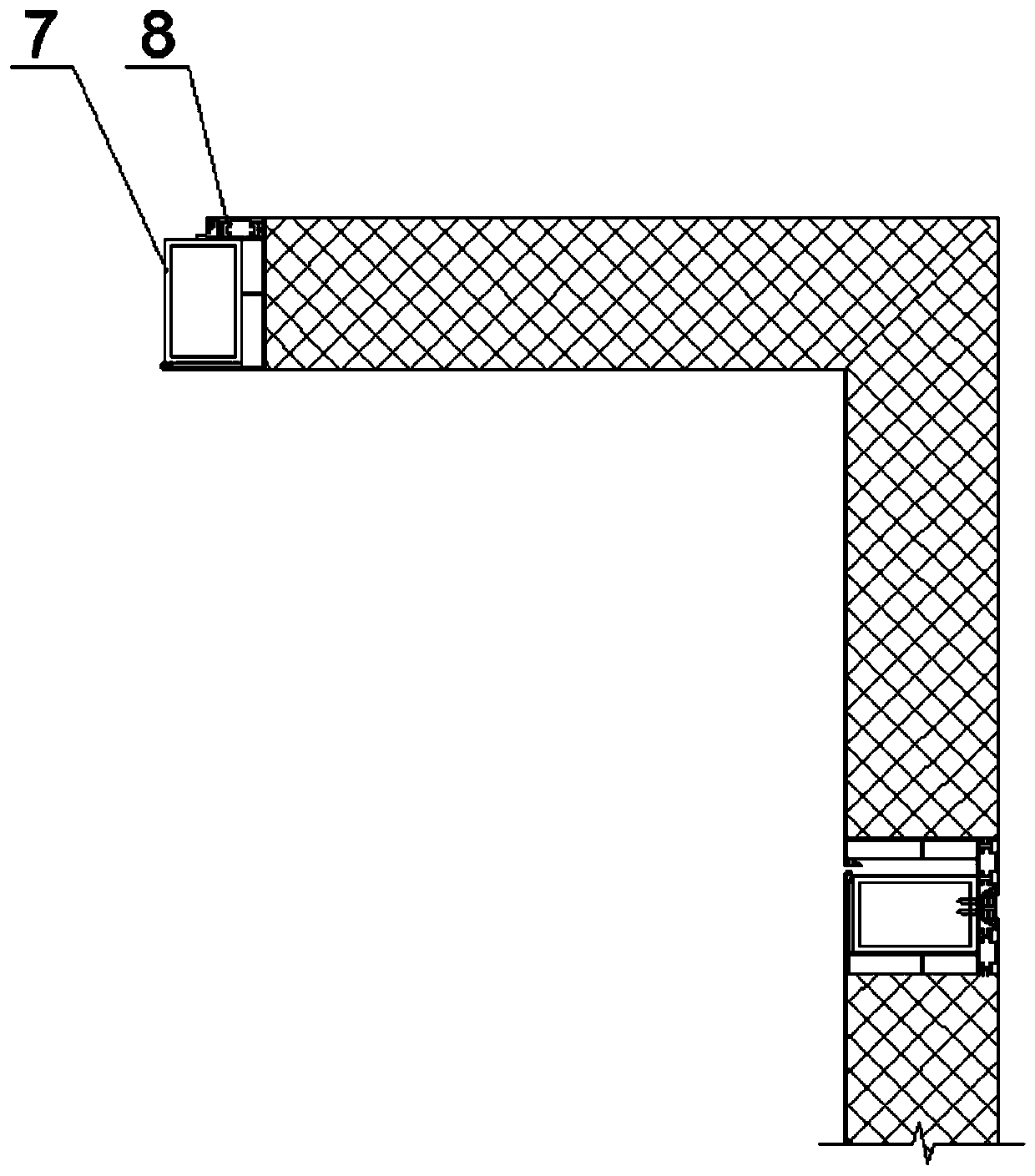

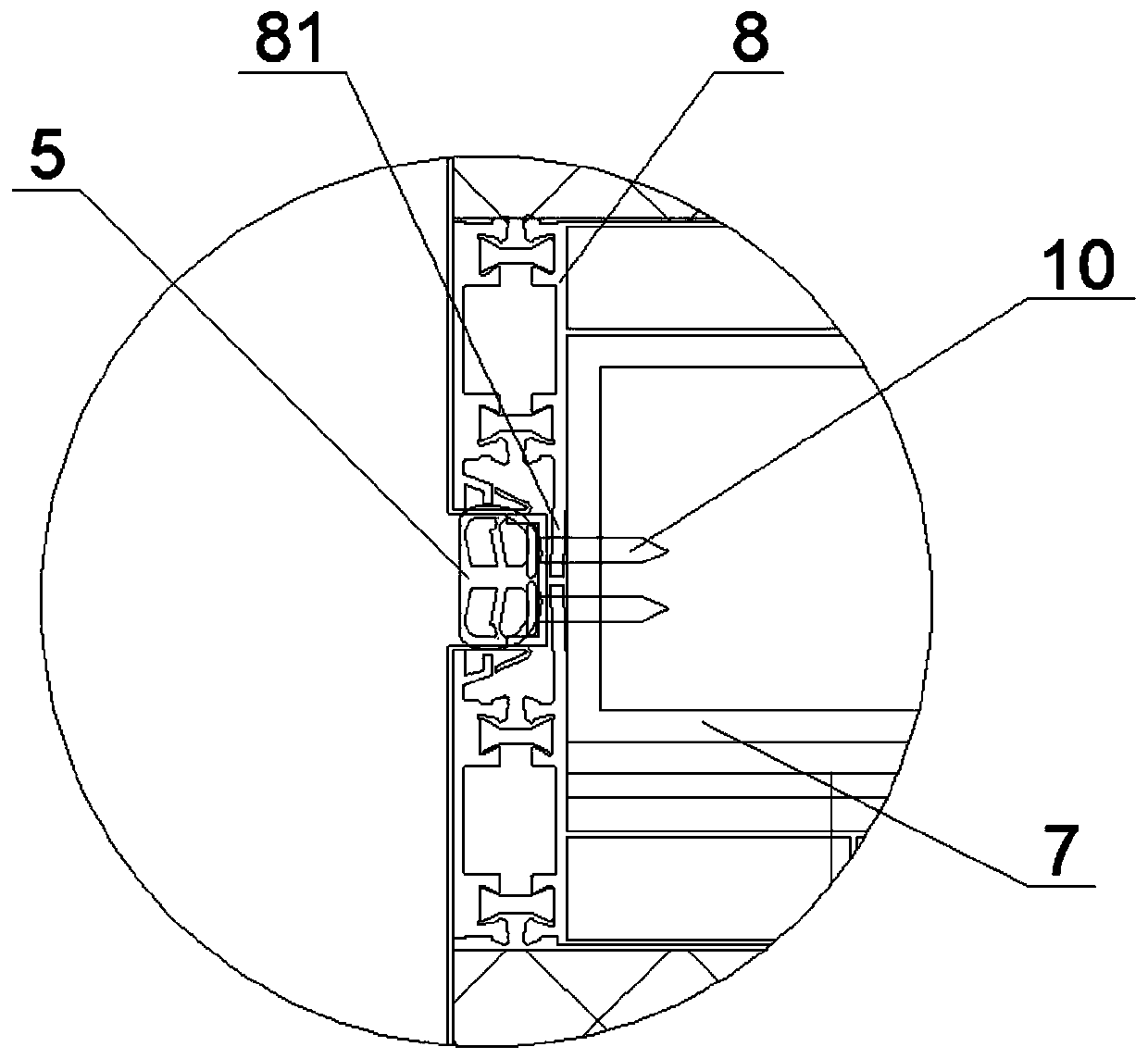

[0025] Such as Figure 1 to Figure 5 As shown, the green prefabricated energy-saving panel wall system provided in this embodiment includes a building curtain wall assembled from a plurality of wall panels and a plurality of metal keels 7 for supporting the building curtain wall. In this embodiment, in order to form a complete In the wall system, a plurality of metal keels 7 are connected in the form of a grid frame connected horizontally and vertically, and the wall panels adopt various forms, which mainly include corner panels 2 for wall corner connections, and panels for installing windows 4. The window sill plate 3 and the connecting plate 1 used for wall composition, the corner plate 2 is an L-shaped metal composite integrated plate, similar to the structure of angle steel, and the metal composite integrated plate adopts the structure of inner and outer metal panels and insulation material sandwich form.

[0026] Both the connection plate 1 and the window sill plate 3 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com