A mobile end face chisel machine

A chiseling machine and mobile technology, which are applied in the processing of roads, building materials, construction, etc., can solve the problems of difficult adjustment of height, great difficulty, and narrow application range, and achieve the effect of improving chiseling effect and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

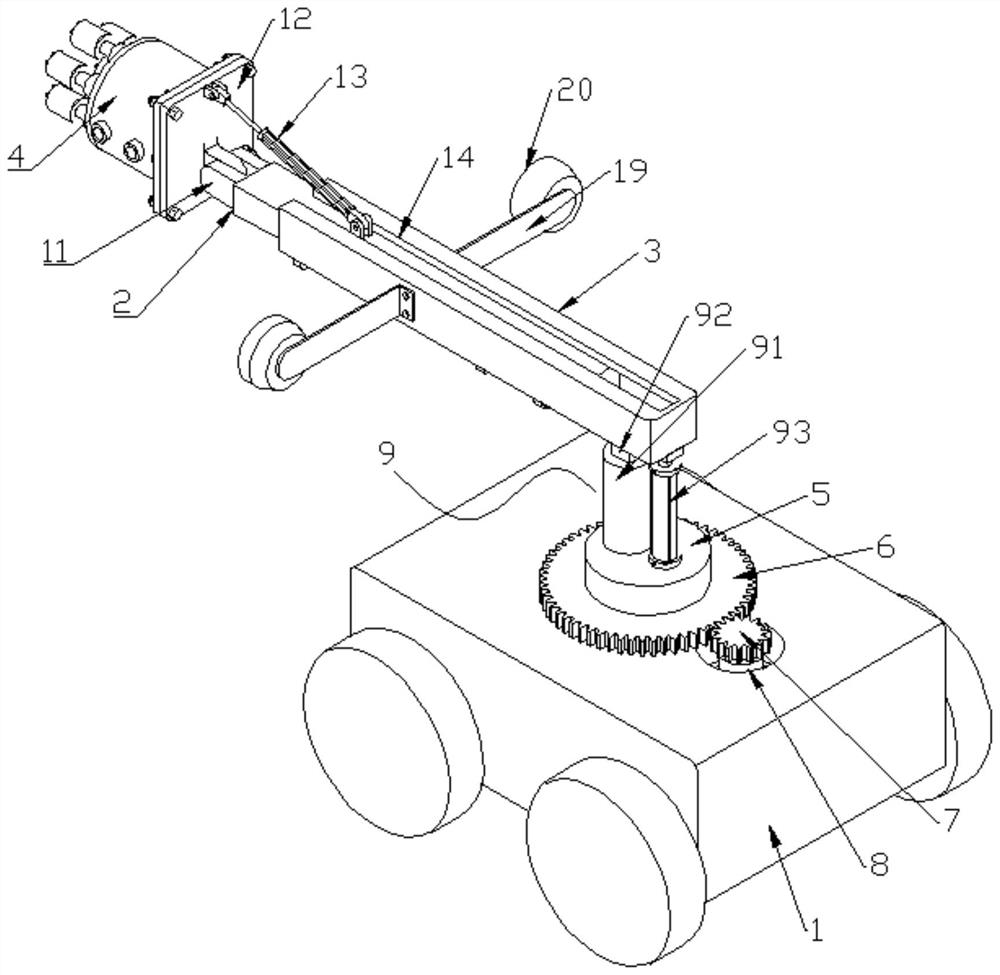

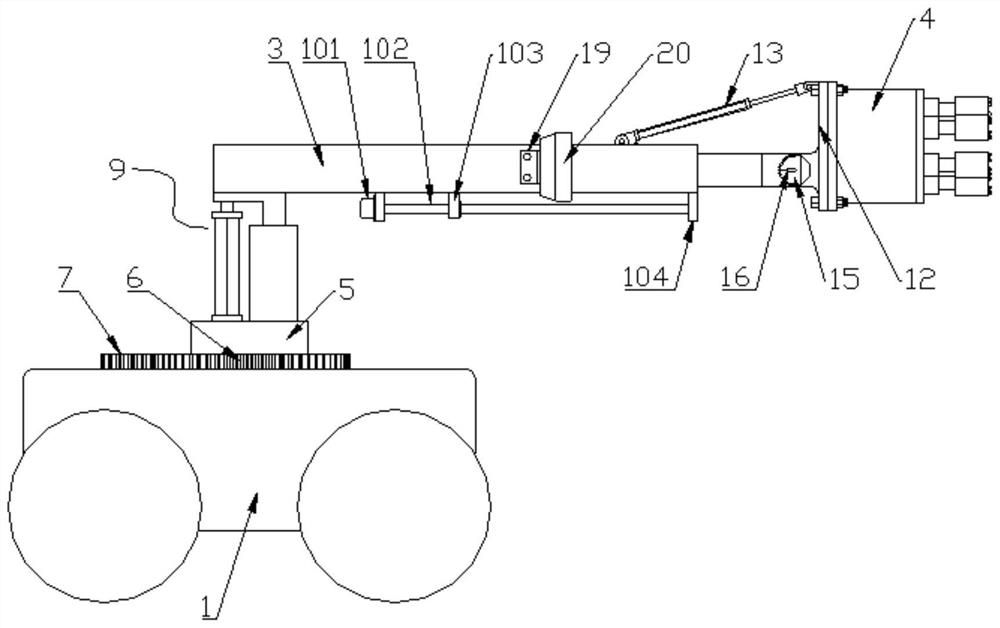

[0031] like Figure 1 to Figure 7 As shown, a mobile end face chisel machine includes a mobile trolley 1, a beam 2, a transverse bracket 3 and a chisel machine body 4. The top of the mobile trolley 1 is rotatably connected to a support seat 5 through a slewing bearing, and the support seat 5 Also be provided with driven gear 6, driven gear 6 meshes with driving gear 7, and driving gear 7 is connected to the output shaft of driving motor 8, and support base 5 is connected with described transverse bracket 3 through lifting mechanism 9, and described The horizontal support 3 is provided with a guide groove, and the crossbeam 2 is slidably connected in the guide groove. The lower end of the crossbeam 2 is connected with a telescopic mechanism that drives the crossbeam 2 to move back and forth. There is an organic base 12, the chisel body 4 is installed on the base 12, an angle adjustment device 13 is also connected between the base 12 and the beam 2, and the two ends of the angle...

Embodiment 2

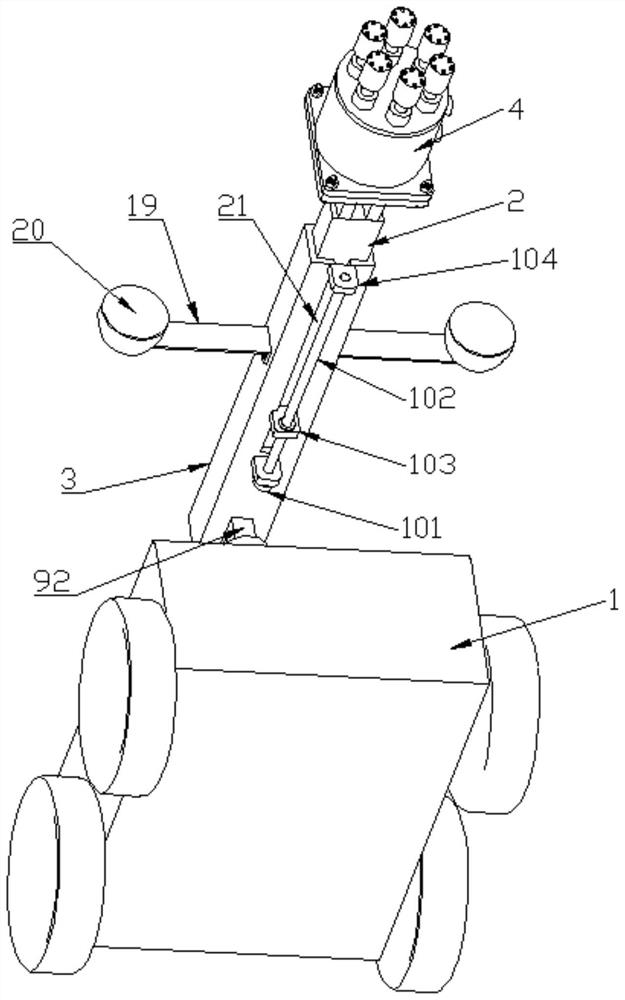

[0039] like Figure 8As shown, a mobile end face chipping machine includes a mobile trolley 1, a beam 2, a transverse support 3 and a chipping machine body 4. The top of the mobile trolley 1 is rotatably connected with a support seat 5 through a slewing bearing. The support seat 5 There is also a driven gear 6 on it, the driven gear 6 is meshed with a driving gear 7, the driving gear 7 is connected to the output shaft of the driving motor one 8, the support base 5 is connected with the horizontal support 3 through the lifting mechanism 9, and the The transverse support 3 is provided with a guide groove, the transverse beam 2 is slidably connected in the guide groove, the lower end of the transverse beam 2 is connected with a telescopic mechanism that drives the transverse beam 2 to move back and forth, and the front end of the transverse beam 2 is connected with a hinge seat 11, which is hinged on the hinge seat 11 There is a machine base 12 on which the chisel body 4 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com