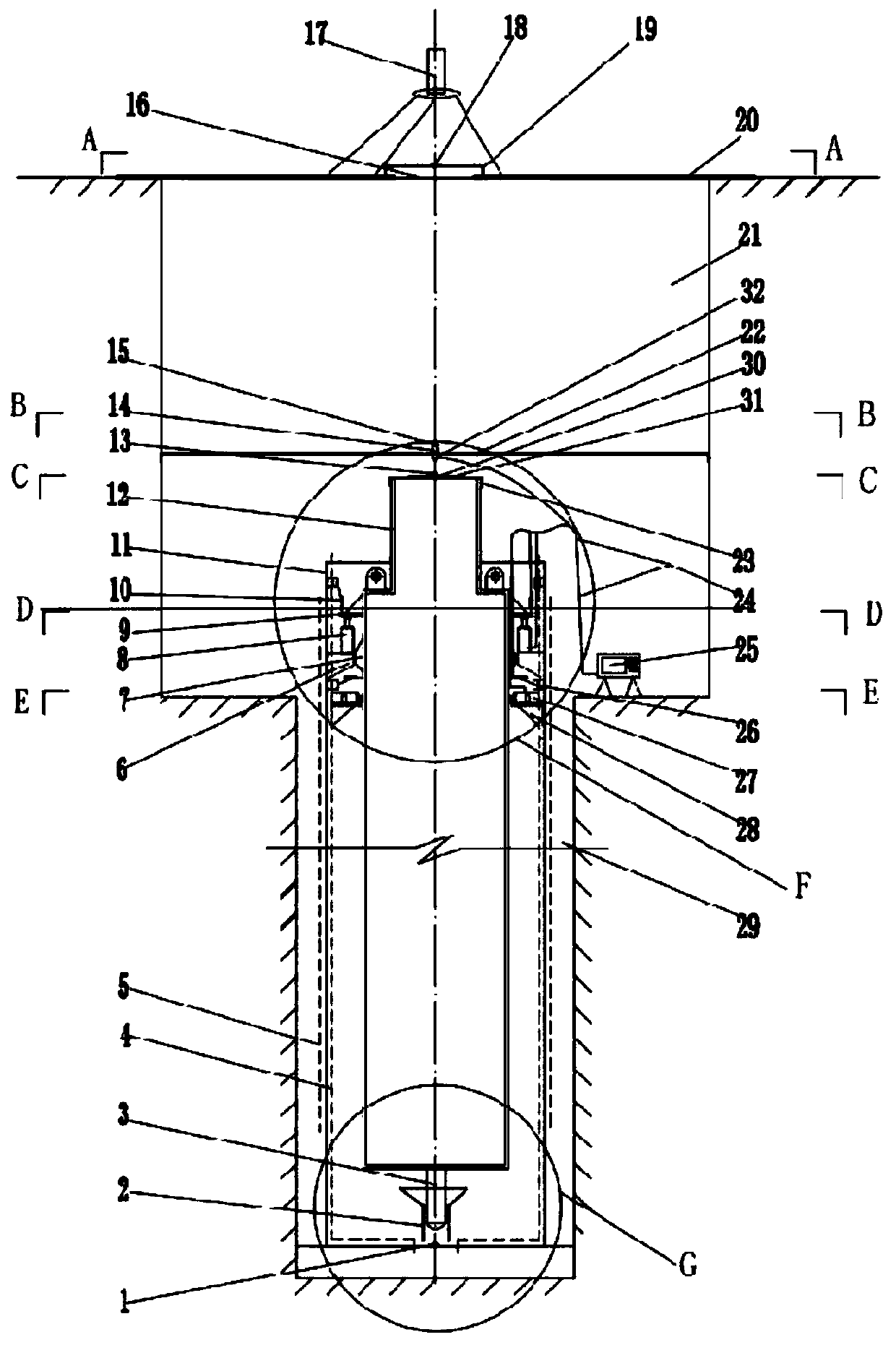

Positioning construction device for deep-buried oil cylinder sleeve

A technology of construction device and cylinder liner, applied in wellbore/well components, earthwork drilling and other directions, can solve problems such as rework, deviation of cylinder sleeve verticality, difficult control of precision, etc., to improve construction efficiency, reduce labor intensity, The effect of convenient underground installation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

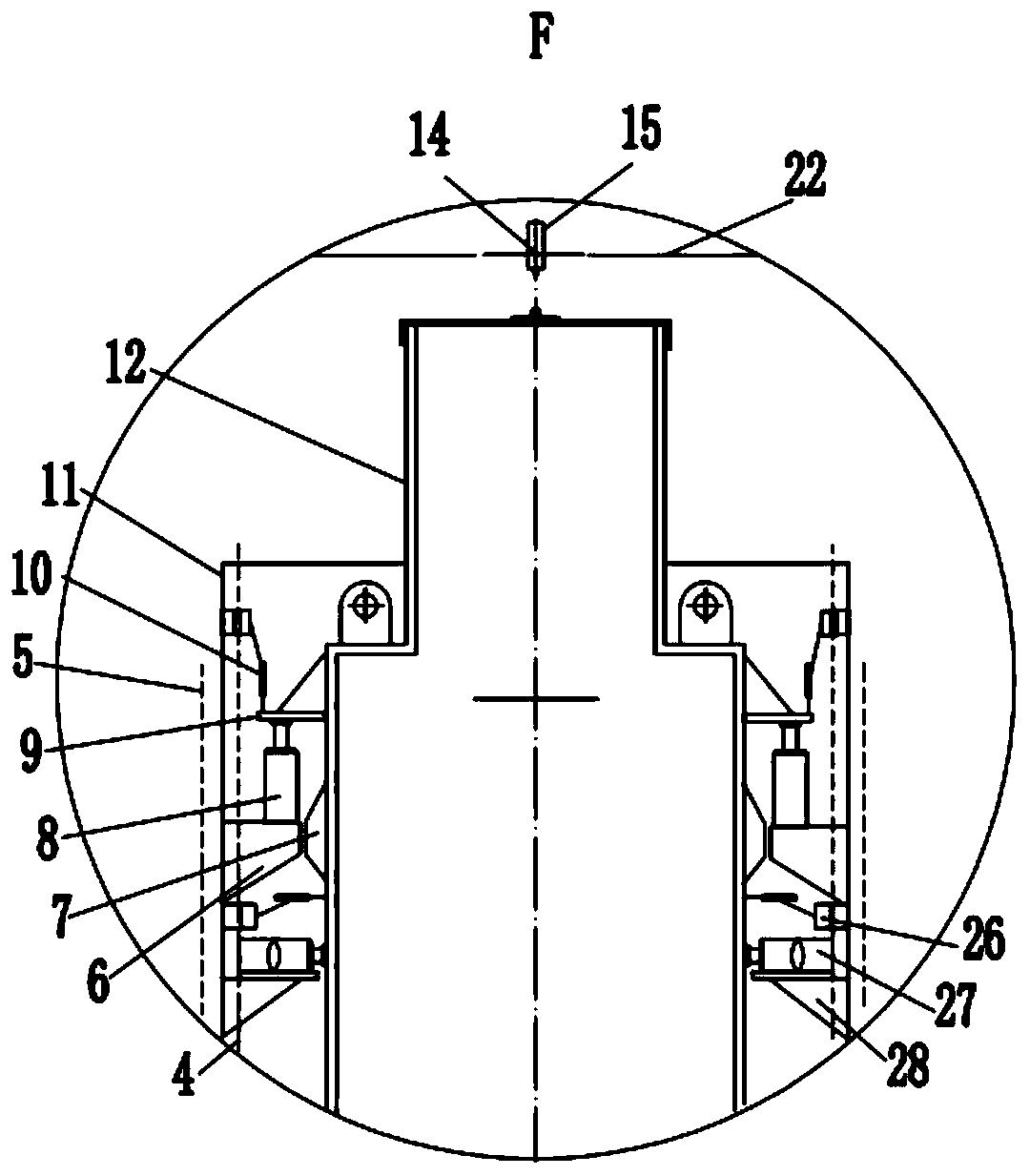

[0026] Construction steps of a positioning construction device for a deep-buried oil cylinder sleeve provided by the present invention:

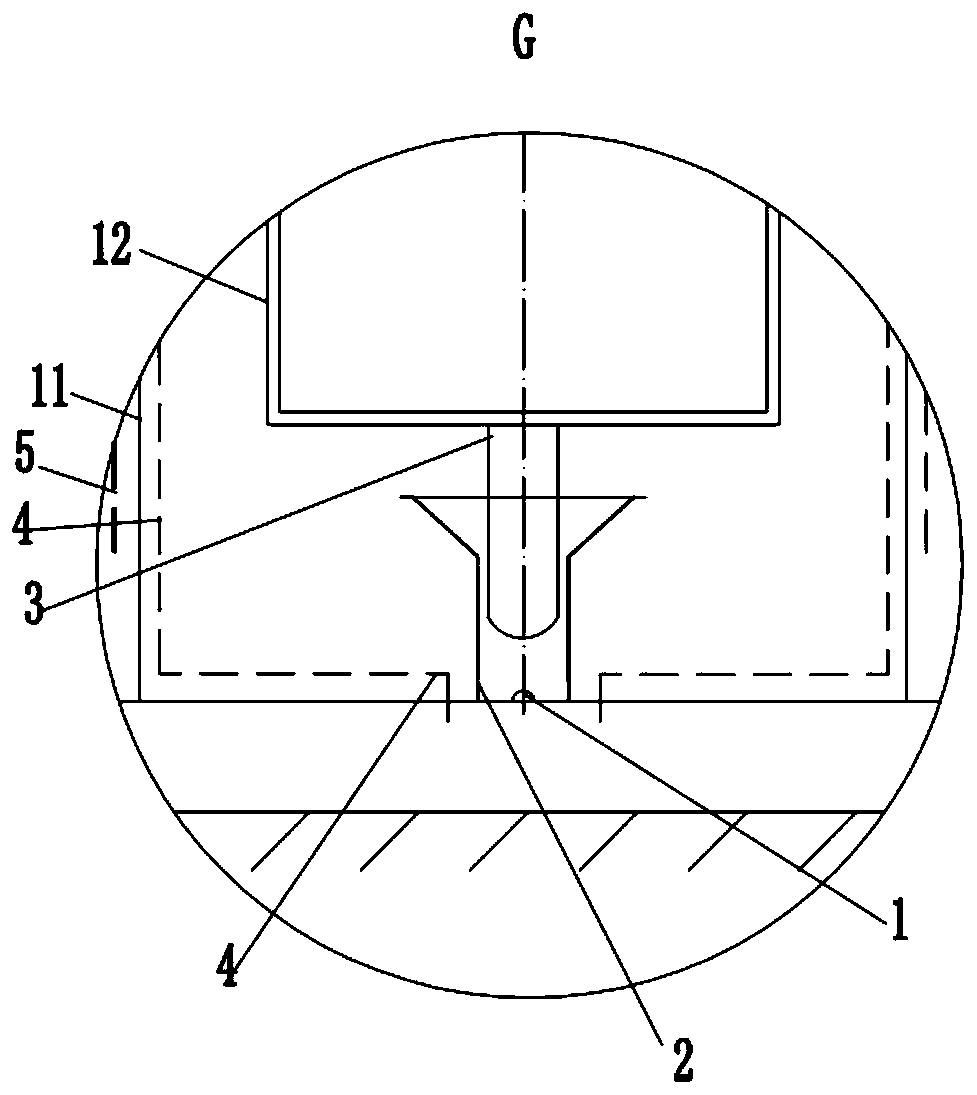

[0027] A, excavate the rectangular trench 21 on the ground, drill the trench well hole 29 downward at the designed hole position on the bottom surface of the trench, hang the outer sleeve 11 into the well hole 29 of the trench, and make the top surface of the outer sleeve 11 high 300-500 mm from the bottom surface of the rectangular ground trough 21, the space between the outer sleeve 11 and the caisson 29 at the bottom of the trough is fixed by grouting.

[0028] , set up the plummet 17, so that the plummet 17 is projected vertically downward along the center of the preset oil cylinder sleeve 12 to the positioning center point 1 of the outer sleeve base, and the positioning seat cover 2 is vertically welded in the outer sleeve 11 on the bottom. Make the positioning center point 1 of the base of the outer sleeve coincide with the preset cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com