Axis trace simulation test bench

A technology for simulating testing and axis trajectory, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. It can solve problems such as project lag and inability to collect test information, and achieve a wide application range and simulation range. broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

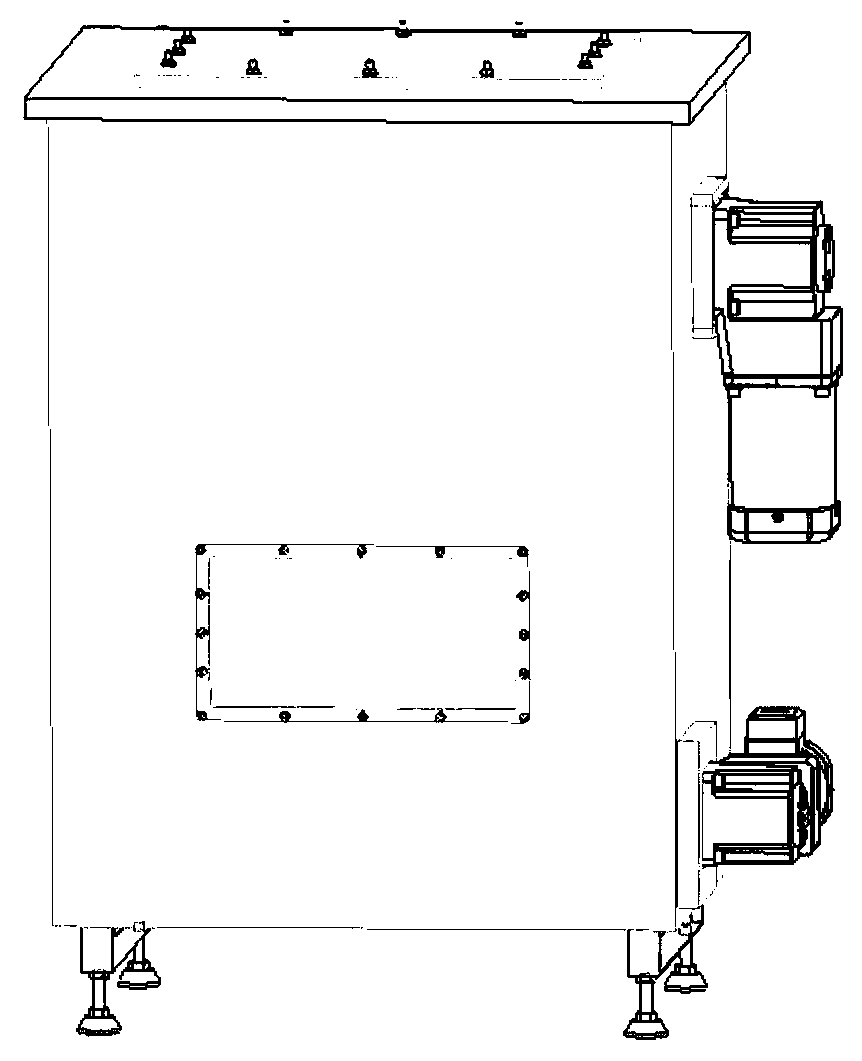

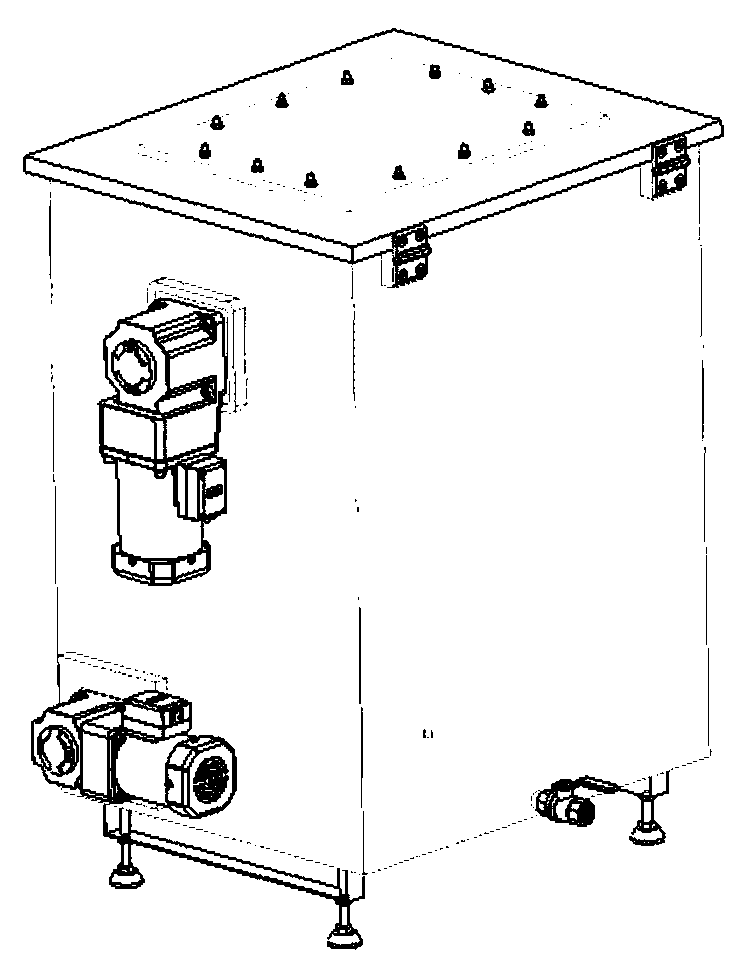

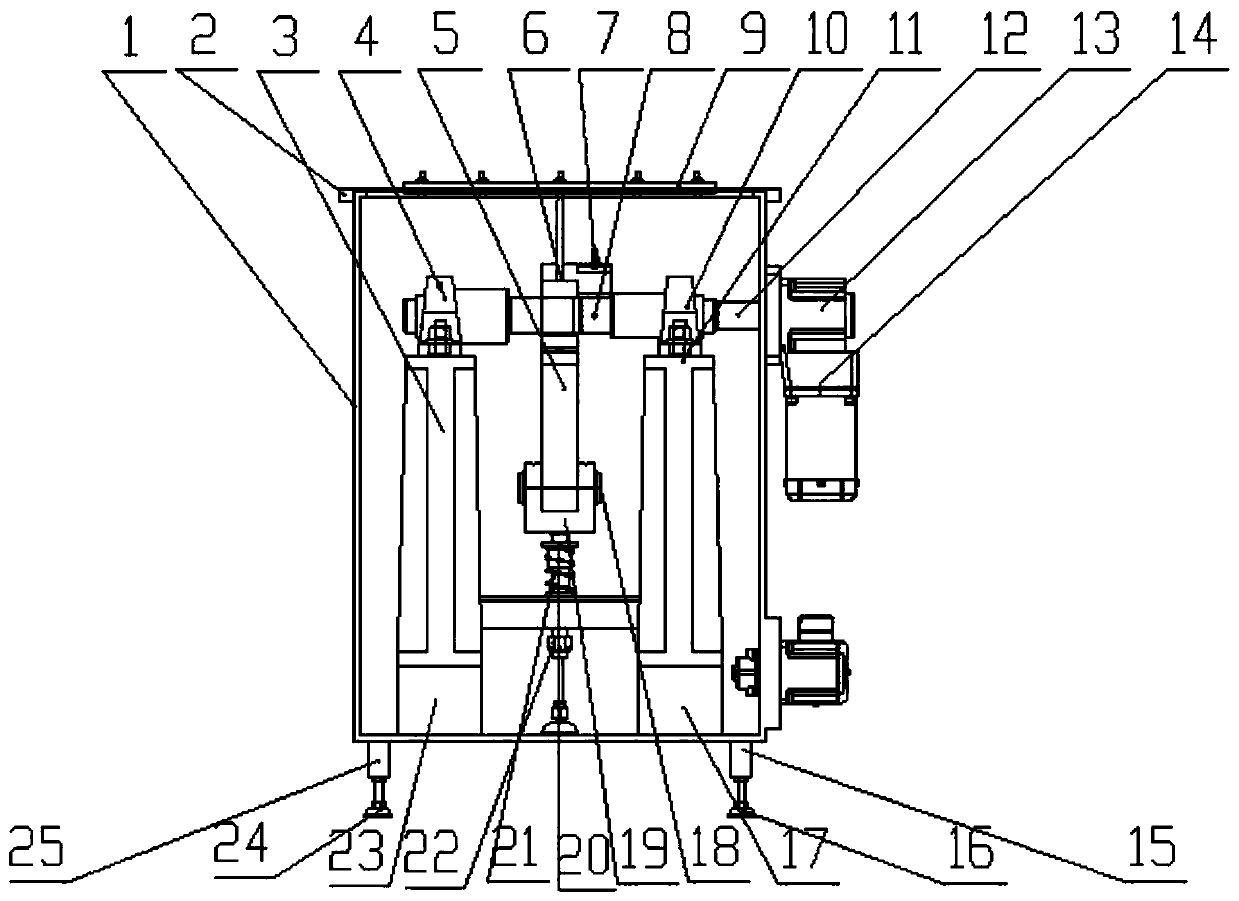

[0019] Combined with Fig. 1-2, a test bench for axis trajectory simulation test mainly includes a sealed box body 1, a test bench top cover 2, a support seat A3, a self-aligning bearing with a seat A4, a connecting rod 5, an oil injection hole 6, and a Y axis Eddy current sensor 7, X-axis eddy current sensor 8, observation port 9, self-aligning bearing with seat B10, support seat 11B, transmission shaft 12, reducer 13, speed regulating motor 14, base mounting beam A15, leveling feet B16, Base B17, shaft pin 18, fork 19, adjustment nut 20, spring 21, safety nut 22, base A23, leveling feet A24, base mounting beam B25.

[0020] The speed regulating motor 14 drives the speed reducer 13 to rotate, the speed reducer 13 drives the transmission shaft 12 to rotate, the transmission shaft drives the connecting rod 5 to rotate, and the connecting rod 58 drives the fork 19 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com