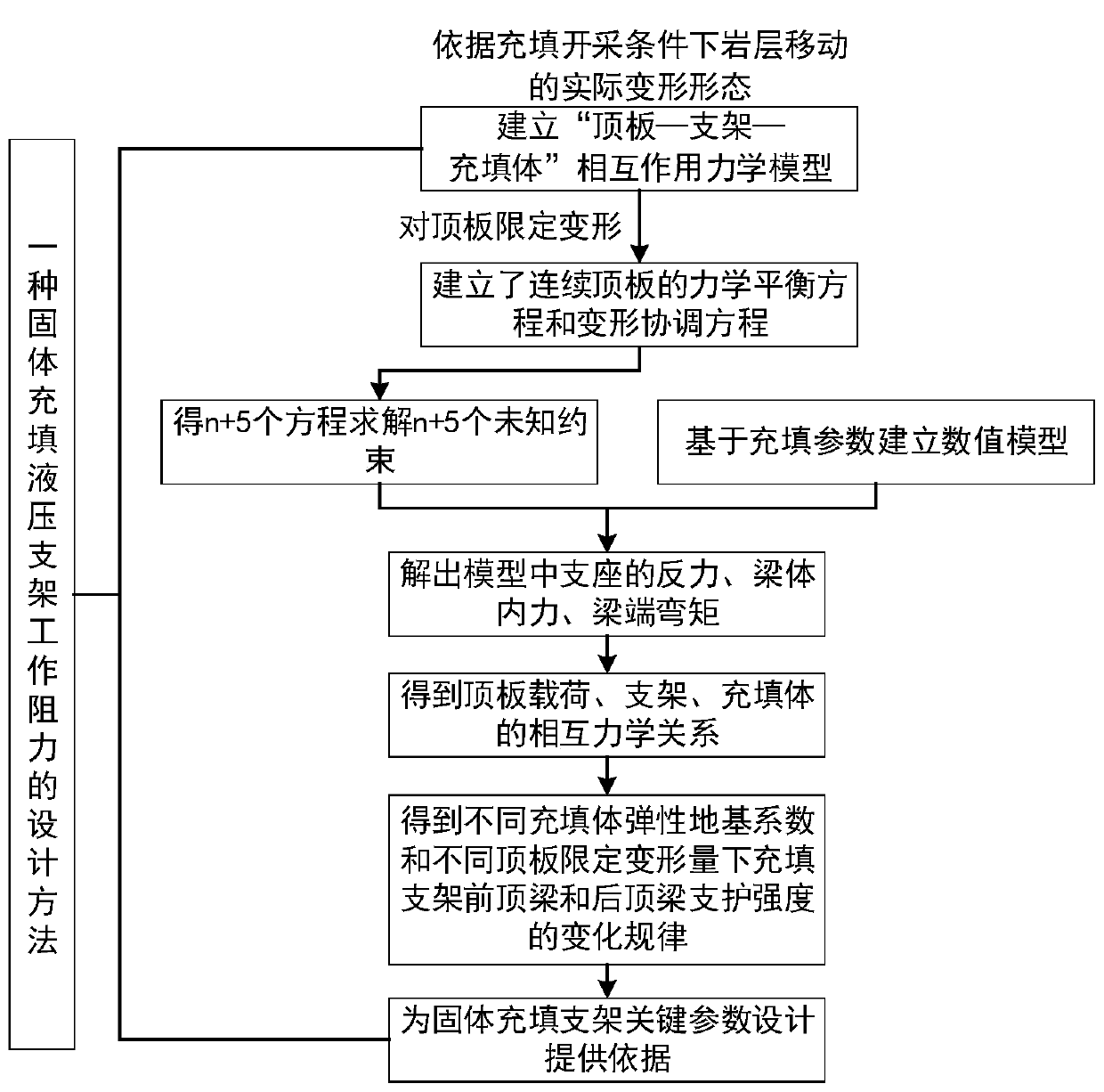

Method for designing working resistance of solid filling hydraulic support

A technology of hydraulic support and working resistance, which is applied in calculation, instrumentation, electrical and digital data processing, etc., can solve the problem of difficulty in determining the changing law of hydraulic support working resistance, and achieve the effect of precise mechanical relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

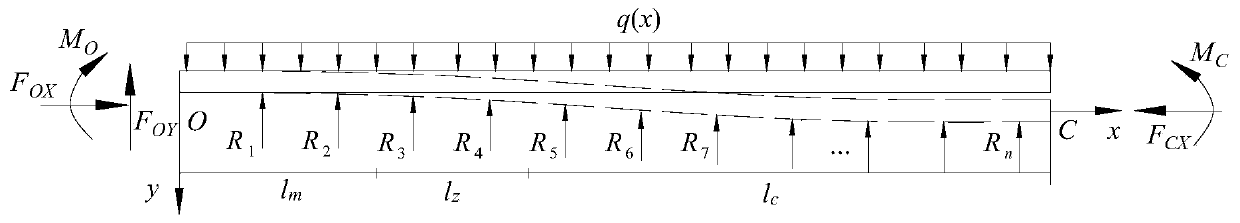

[0049]In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

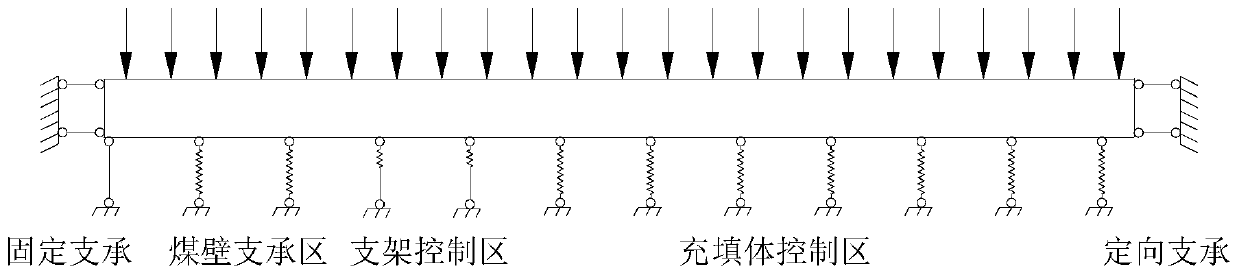

[0050] The "continuous curved beam" structural model expounds the formation process of the continuous curved beam and its geometric and mechanical characteristics. Due to the continuity of the structure, the transmission of force is maintained, thereby reducing the disturbance to the stress field of the original rock, and revealing in essence The form of rock formation movement in filling mining.

[0051] As for the movement of rock formations mined by the caving method, long-term practical observation and research have shown that with the advancement of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com