Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, and no separate inflatable cushions, etc., which can solve the problem of reducing the joint rubber layer of the full joint rubber layer, maintaining air permeability prevention and handling stability, Problems such as the impact on tire manufacturing performance, to achieve the effect of taking into account air permeability, excellent air permeability and handling stability, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

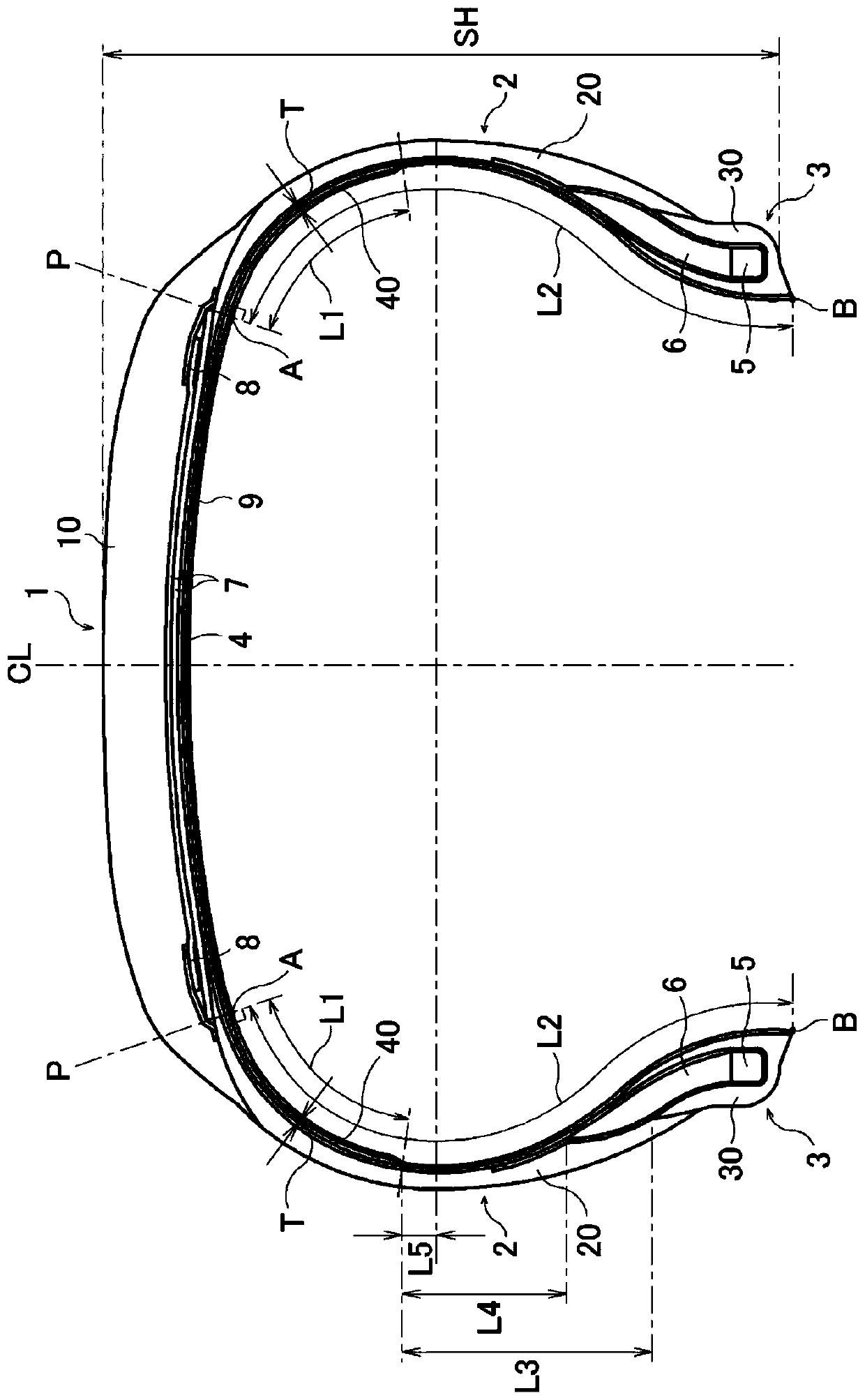

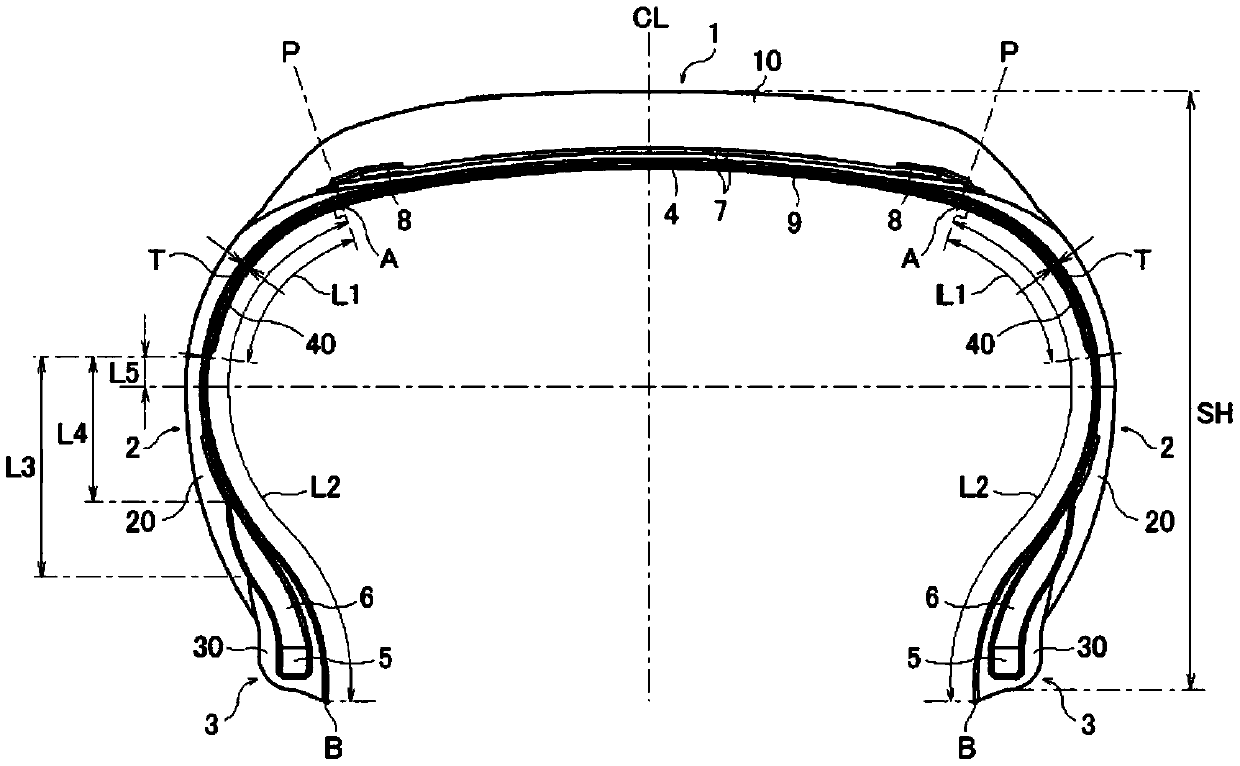

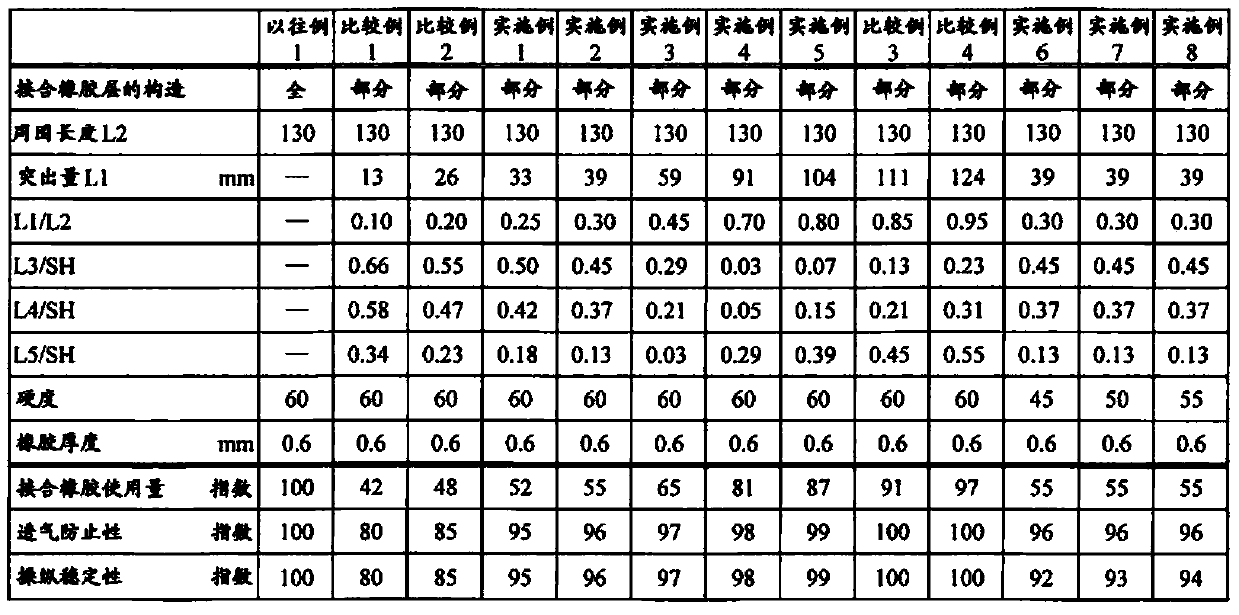

[0033] The tire size is 195 / 65R15, with figure 1 The basic structure shown, and the structure of the joint rubber layer, and the protrusion amount L1 of a part of the joint rubber layer to the bead portion side with respect to the perpendicular line P drawn from the outermost end portion of the belt layer in the tire width direction toward the inner liner , the length L2 around the inner surface of the tire from the intersection point A of the vertical line P and the inner surface of the tire to the head end point B of the bead toe, and the distance between the end of the partially bonded rubber layer and the radially outer end of the rim cushion rubber The ratio of L3 to the tire section height SH (L3 / SH), the ratio of the distance L4 between the end of the partially bonded rubber layer and the tire radially outer end of the bead filler to the tire section height SH (L4 / SH ), the ratio of the distance L5 between the end of the partially bonded rubber layer and the tire maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com