Cable lifting device for maintenance

A lifting device and cable technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of uncompact cable laying, reduced power supply reliability, insufficient lifting height, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

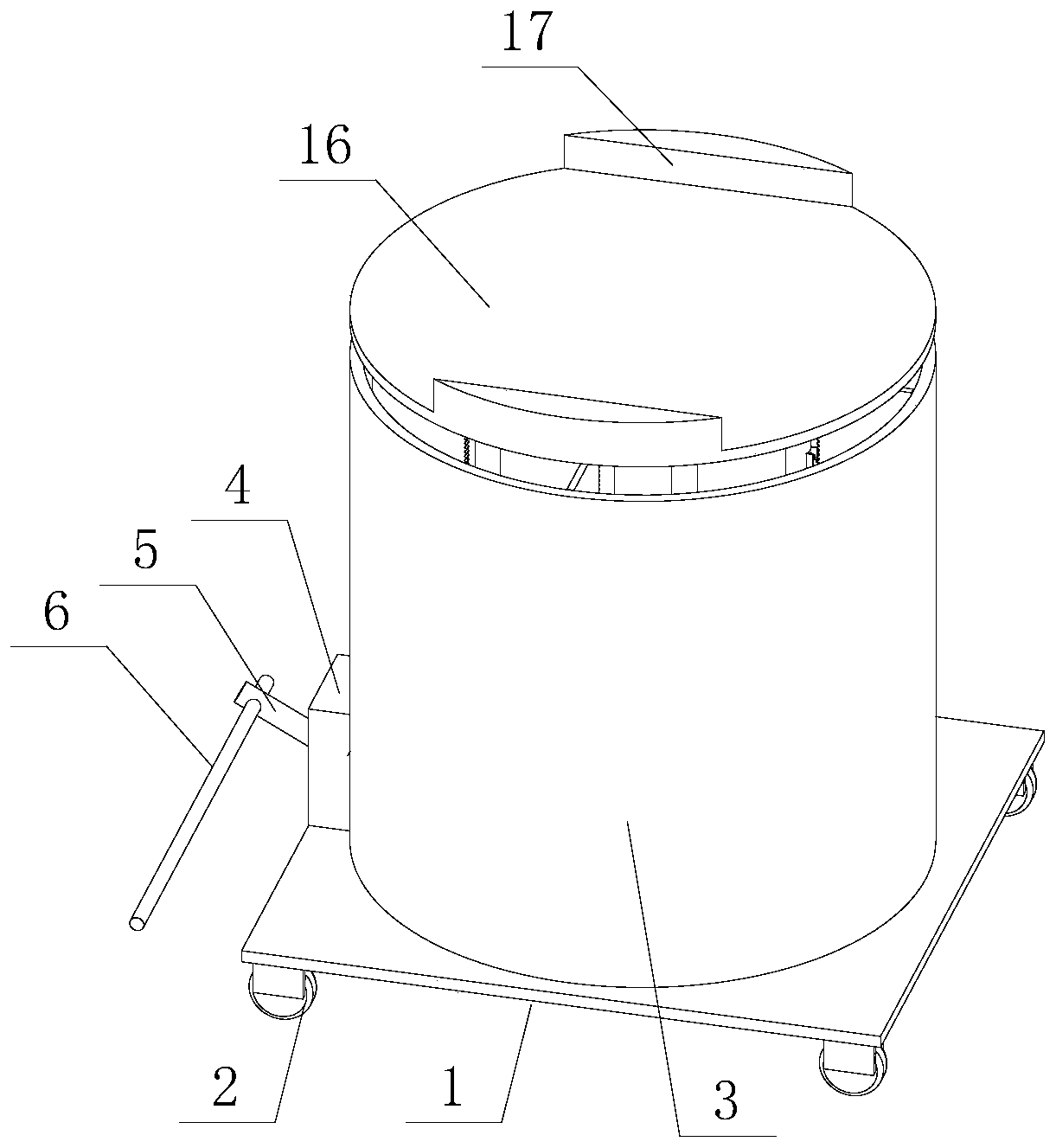

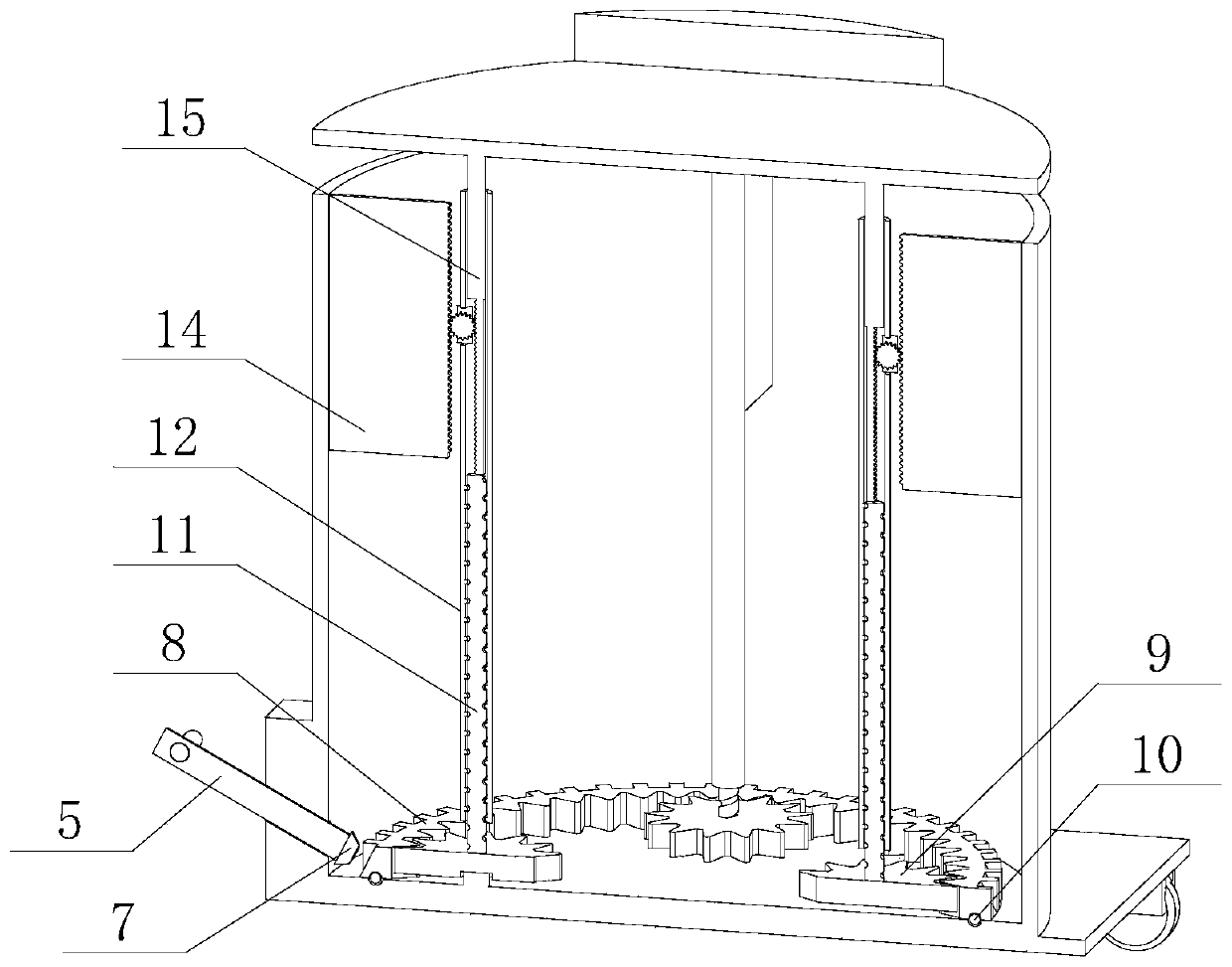

[0027] Such as figure 1 The shown cable lifting device for maintenance aims to provide a stable, multi-section lifting device, and reduce labor intensity on the premise of ensuring the personal safety of construction personnel.

[0028] The overall structure is as figure 1 As shown, the entire lifting device is installed on the base 1, and the bottom surface of the base 1 is equipped with a universal wheel 2. The universal wheel 2 is equipped with a brake device, which can be stably fixed on the ground and can be kept stable during the lifting process.

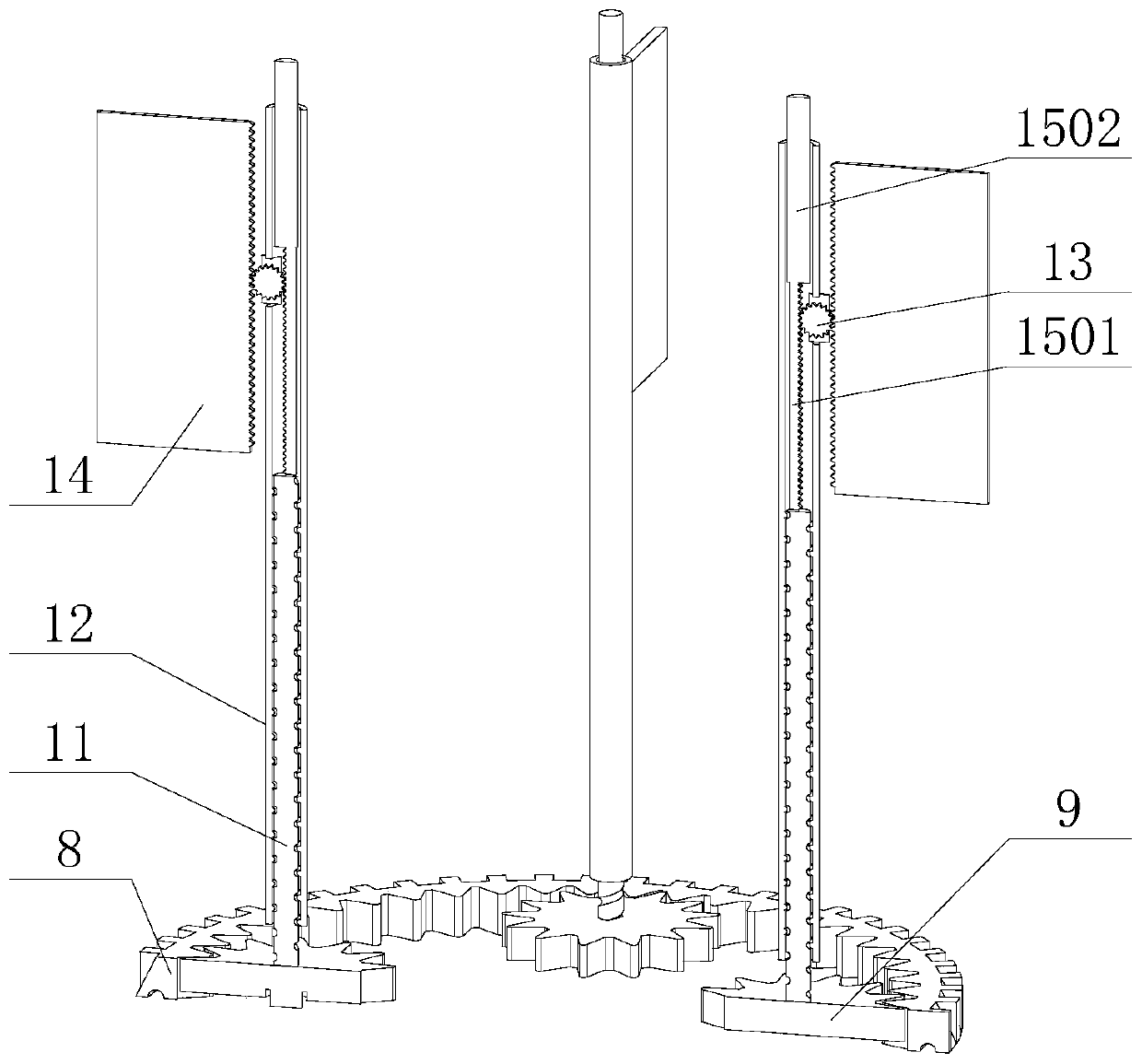

[0029] Such as figure 1 and figure 2 As shown, a cylindrical casing 3 is installed on the base 1, and a mounting seat 4 is installed on the outer surface of the casing 3 for installing the rotating shaft 5, and a rocker 6 is inserted on the rotating shaft 5 placed outside the casing 3, The first gear 7 is installed on the rotating shaft 5 placed in the casing 3. In order to make the manual drive labor-saving, the device ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com