Spanning device for erecting cables across ditches

A technology for erecting cables and ravines, which is applied in the field of line erection equipment, can solve problems such as inability to cross ravines, and achieve the effect of ensuring stability and increasing counterweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

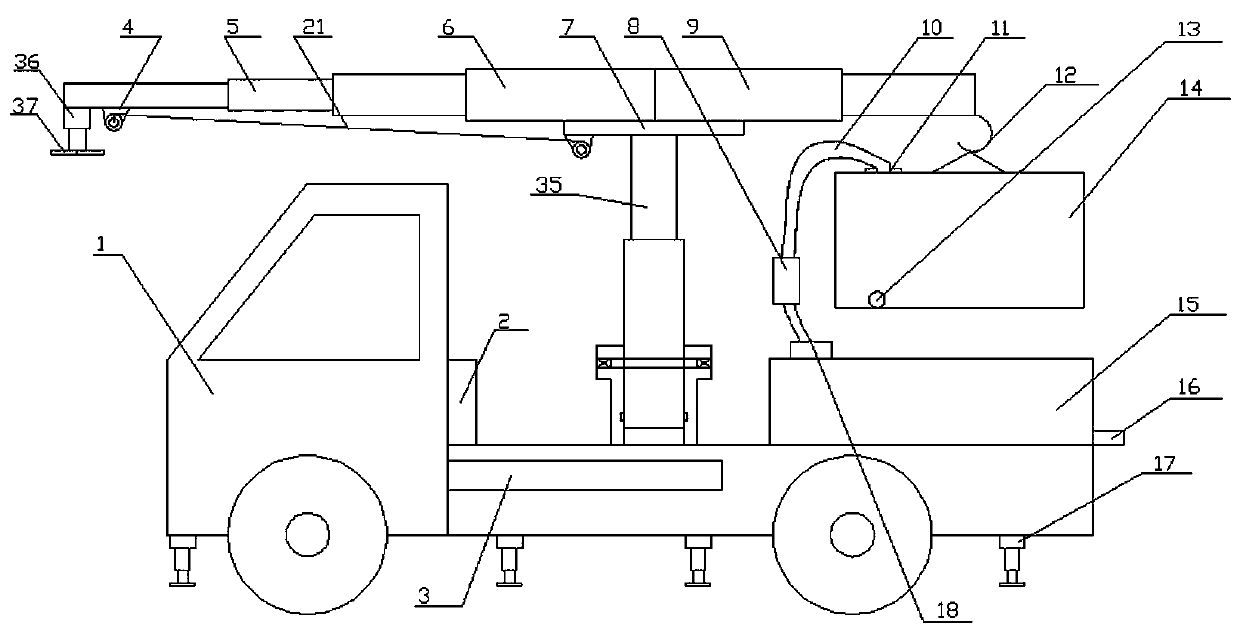

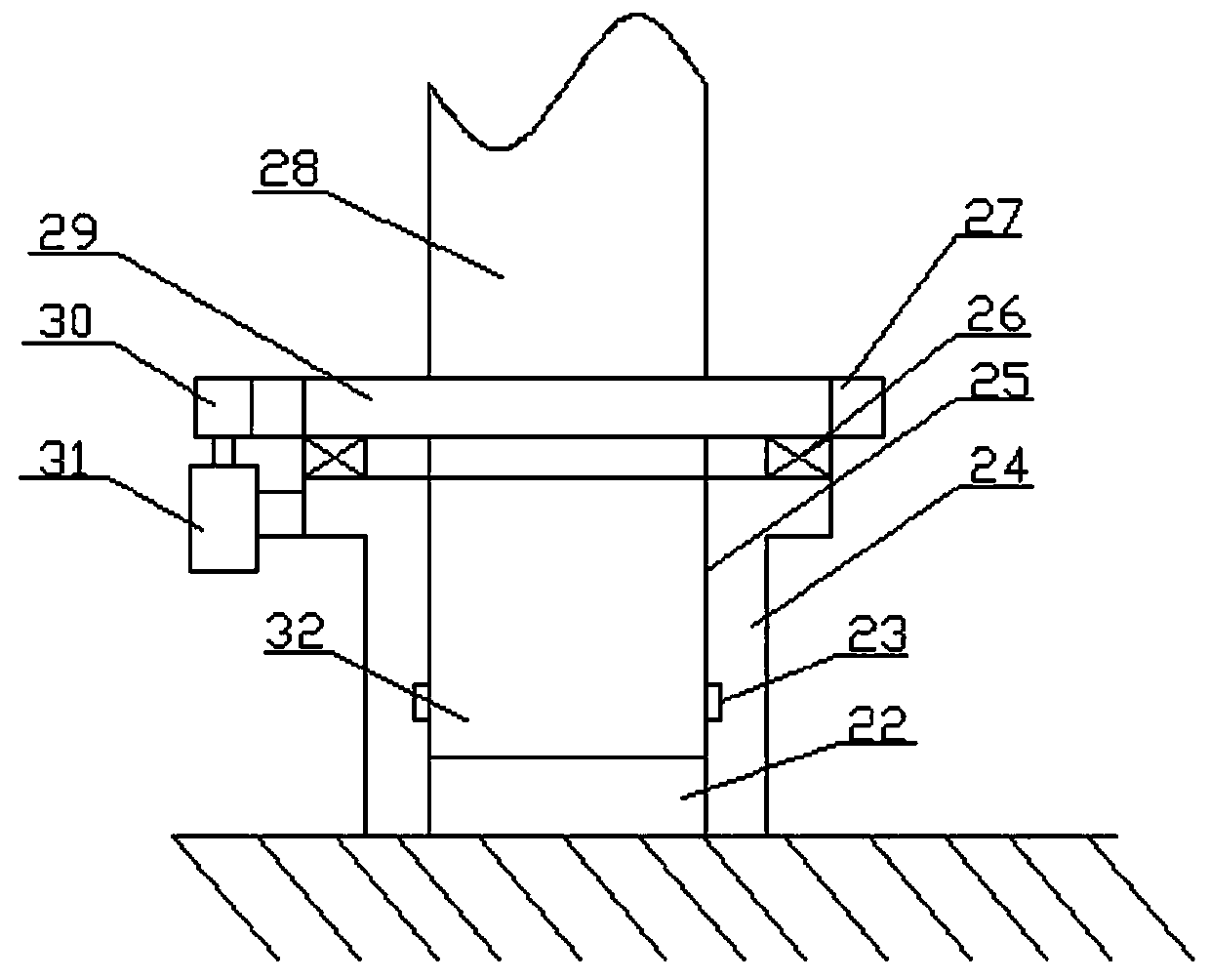

[0026] Such as Figure 1-4 Shown: a spanning device for erecting cables across ravines, including a carrier vehicle 1, a supporting mechanism arranged at the lower part of the carrier vehicle 1, a rotating mechanism arranged on the carrier vehicle, and a telescopic telescopic mechanism arranged on the rotating mechanism mechanism, a spanning mechanism arranged at the upper end of the telescopic mechanism, a counterweight mechanism disposed at one end of the spanning mechanism, and a counterweight mechanism disposed on the carrier vehicle for controlling the supporting mechanism, the rotating mechanism, the telescoping mechanism, the spanning mechanism and the counterweight The control mechanism of the heavy mechanism;

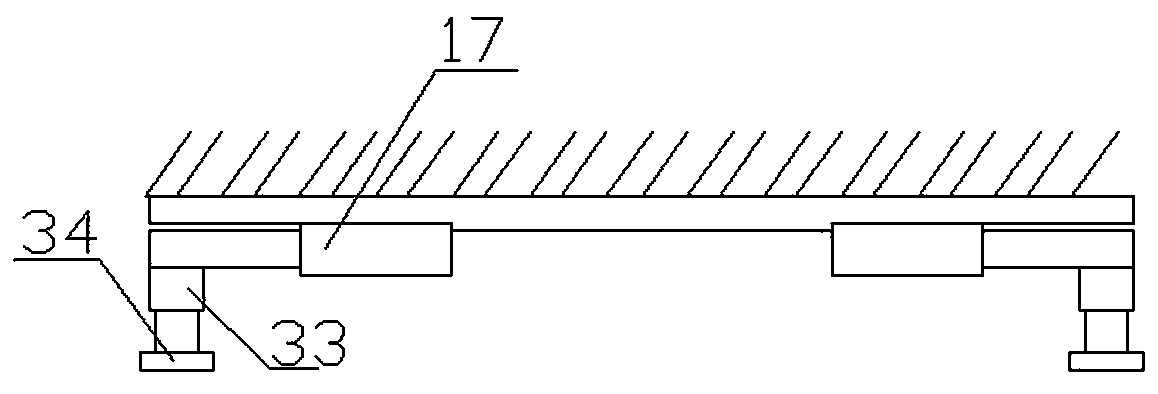

[0027] Described support mechanism comprises a plurality of lateral telescopic arms 17 arranged on the peripheral side of the vehicle, a vertical telescopic arm 33 arranged at the end of the lateral telescopic arm 17, and a support provided at the lower end of ...

Embodiment 2

[0035] Such as Figure 4 Shown, its difference with embodiment one is:

[0036] An electric hoist is arranged on the hanging hook, and the lower end of the electric hoist is connected with a counterweight water tank.

[0037] In this embodiment, the electric hoist can be used to lift the heavy counterweight water tank to a certain height to ensure that it can be loaded on a car or close to the ground. Of course, a manual hoist can also be used for lifting.

Embodiment 3

[0039] Such as Figure 5 Shown, its difference with embodiment two is:

[0040] A MEMS gyroscope 19 and a MEMS accelerometer 20 are arranged at the center of the vehicle.

[0041] The MEMS gyroscope and MEMS accelerometer adopted in this embodiment can detect the change of the center of gravity, so that the operator can be prompted by the computer to deal with it in time, such as extending the telescopic arm of the counterweight, or adding more counterweights to the counterweight water tank. heavy water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com