Fully sealed, buffer and shock-proof secondary transfer system

A fully-sealed, impact-resistant technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of impact damage to the lower conveyor, material throwing, etc., and achieve the effect of good application and promotion prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

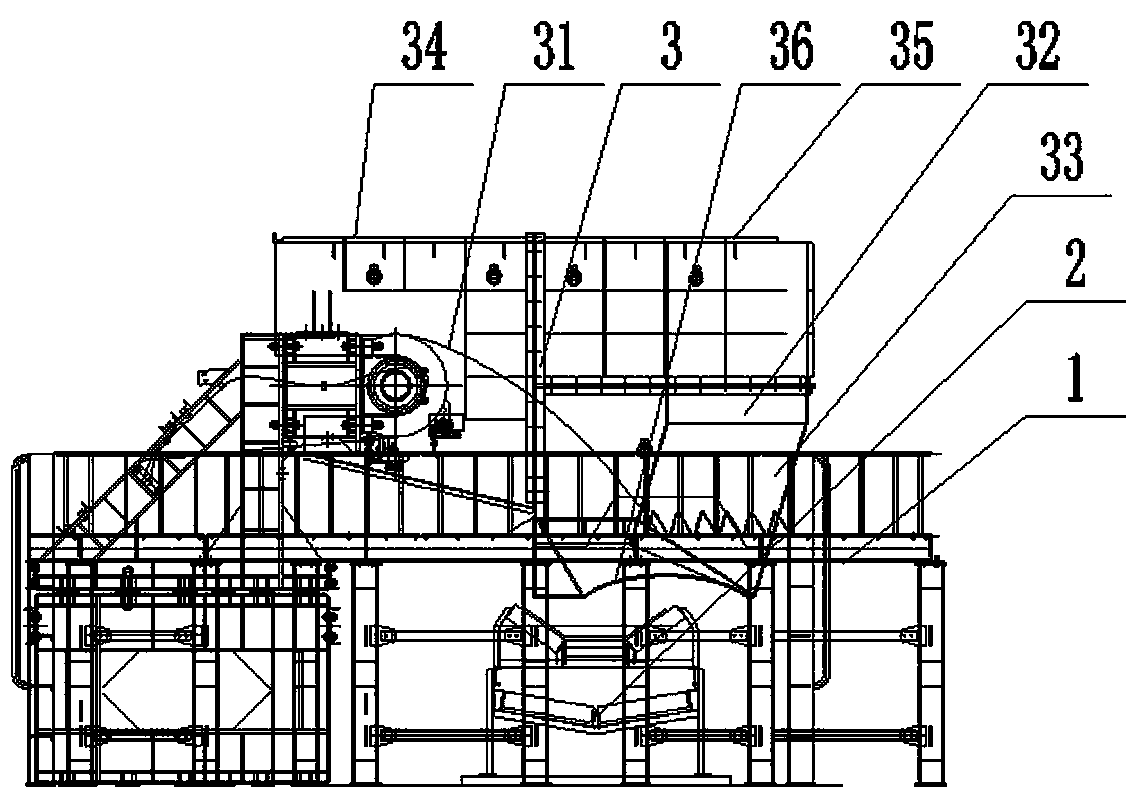

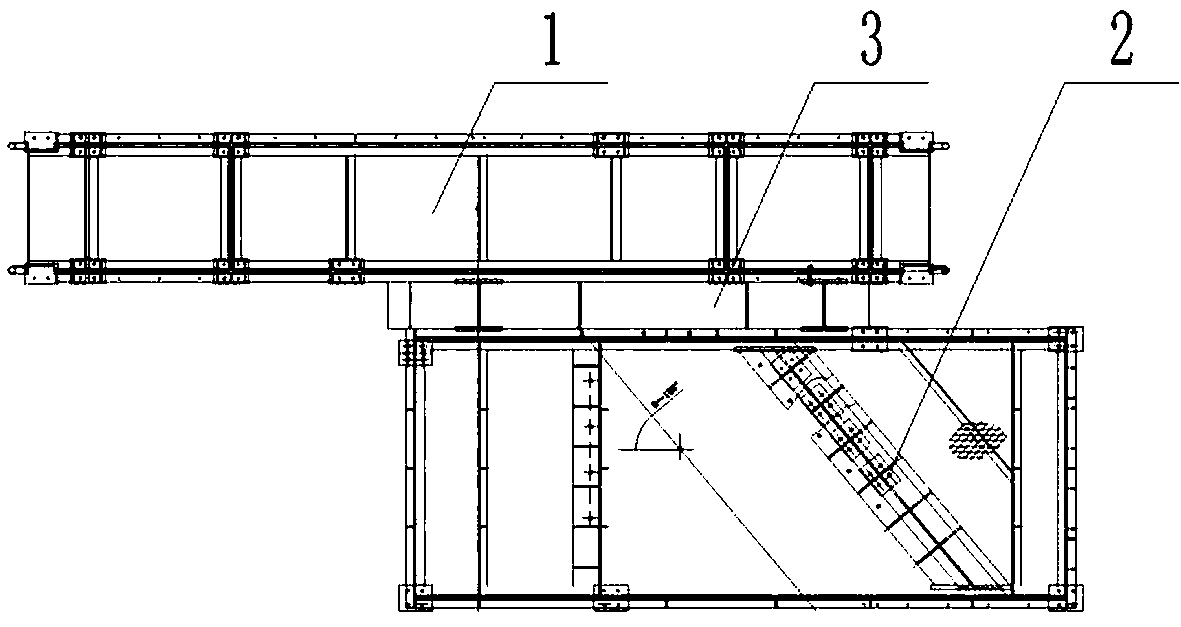

[0020] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a fully sealed, cushioning and anti-shock secondary transfer system, including a primary transfer device 1 and a secondary transfer device 2, the primary transfer device 1 is located above the secondary transfer device 2, and the primary transfer device 2 is located above the secondary transfer device 2. The discharge end of the reloading device 1 is provided with a reloading transition device 3, and the material falls on the secondary reloading device 2 through the primary reloading device 1 through the reloading transition device 3;

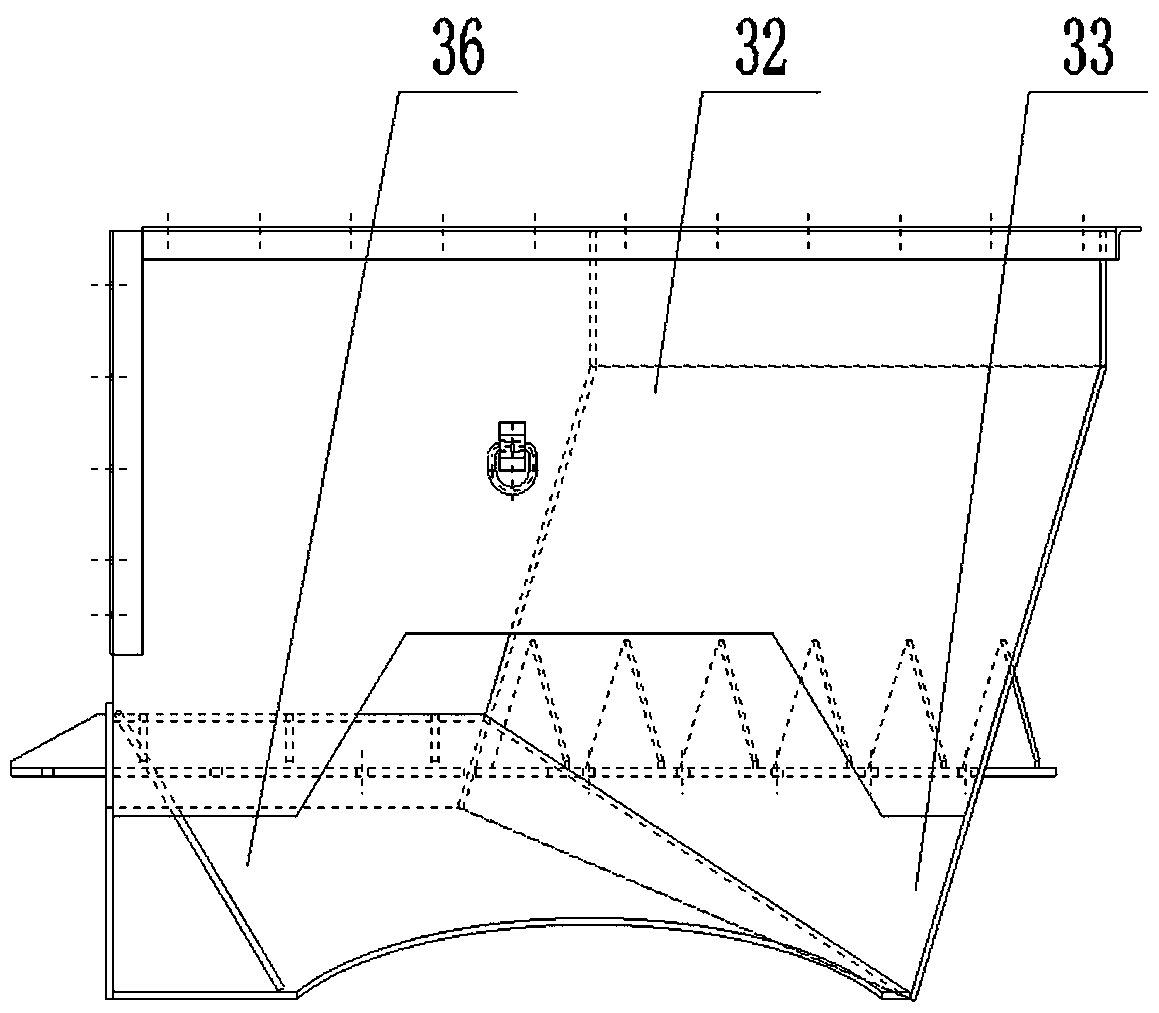

[0021] The structure of the transfer transition device 3 is: including a diversion plate 31, a coal hopper 32 and an oblique material receiving plate 33, one end of the diversion plate 31 is connected to the end of the discharge port of the primary transfer device 1, and the other end is Connected to the feed port of the coal leakage hopper 32, the turning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com