Preparation method of cut tobacco moisture gradient experiment sample

A technology for cut tobacco and moisture, applied in the field of silk making, can solve the problems of small coverage of two gradient moisture, difficult to control humidity and equilibrium time, and inability to achieve consistent moisture on the surface of cut tobacco, so as to avoid the problem of artificial crushing and sampling environment Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

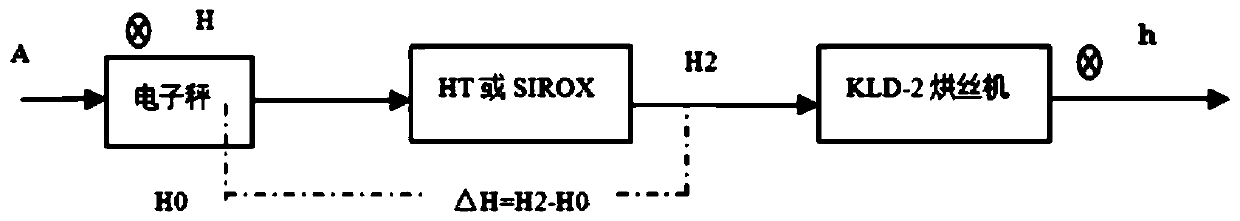

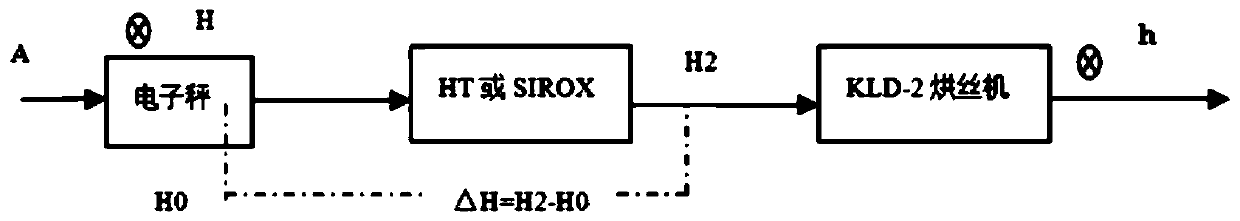

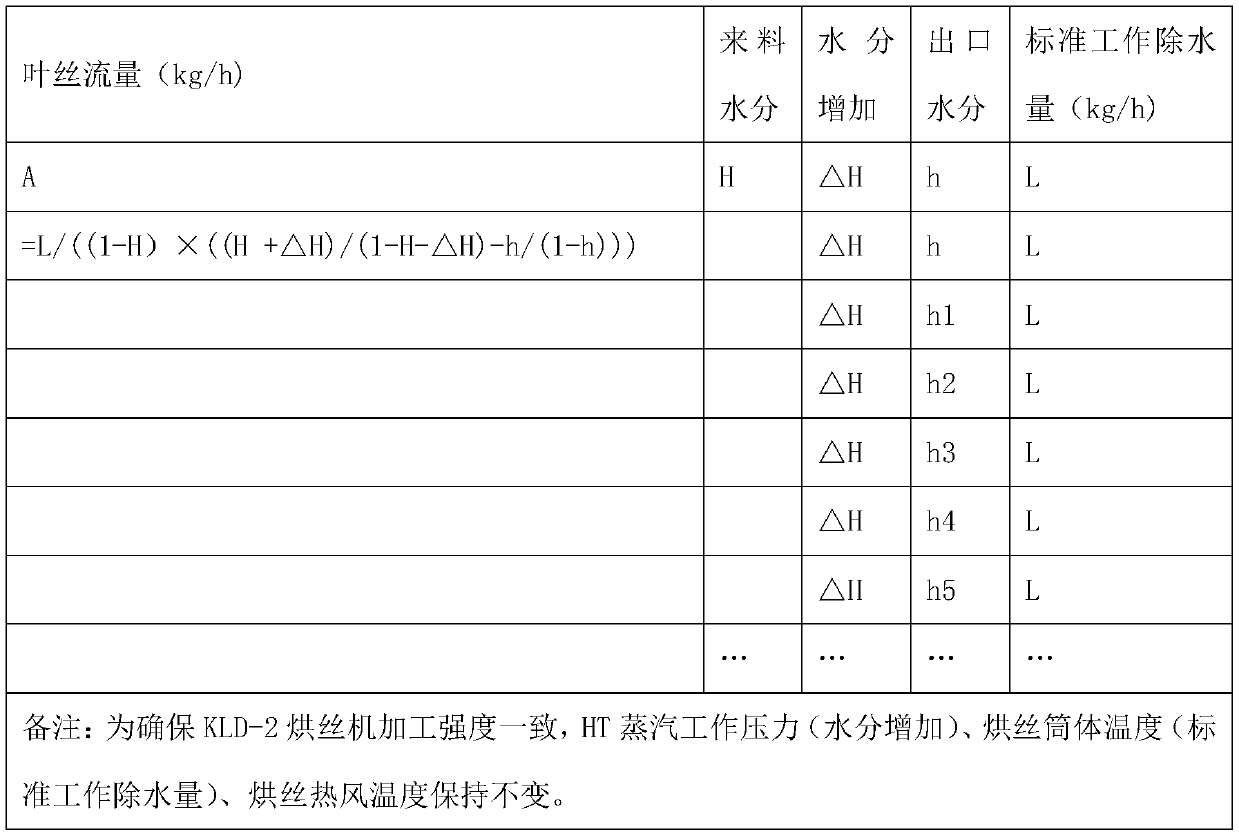

[0033] Such as figure 1 As shown, it is the KLD-2 silk drying process such as the process flow, in the figure On behalf of the online moisture meter, A is the leaf silk flow rate, H0 is the oven method to detect the incoming moisture, H is the online moisture meter to display the incoming moisture, H2 is the oven method to detect the moisture at the outlet of HT or SIROX, h is the outlet moisture setting of the silk dryer Value, △H represents the water increase of HT or SIROX, that is, △H=H2-H0. It should be noted that in the present invention, HT refers to a warming and humidifying machine, and SIROX refers to an expansion unit. The functions of the two are basically the same, but the expansion effect of the latter is more obvious than that of the former.

[0034] The prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com