Automatic tooth undercut filling printing method based on tooth feature points

A technology of automatic filling and feature points, which is applied in dentistry, orthodontics, dental prosthetics, etc., can solve the problems of hard to take out the positive mold of the teeth, lack of tooth undercuts, and difficult to wear, etc., to achieve the convenience of molding work and the degree of automation High, less manual operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the drawings and embodiments of this specification.

[0051] First, obtain a digital tooth model: In order to obtain a tooth model, firstly, it is necessary to obtain a plaster model of the jaw through occlusal silicone rubber, and then obtain the three-dimensional data of the jaw by optically scanning the plaster model, and then perform digital segmentation on the model of the jaw. The final teeth are numbered and named to facilitate later operations. The digital oral system provides data support for 3D printing invisible aligners and later orthodontic treatment programs by establishing digital tooth models.

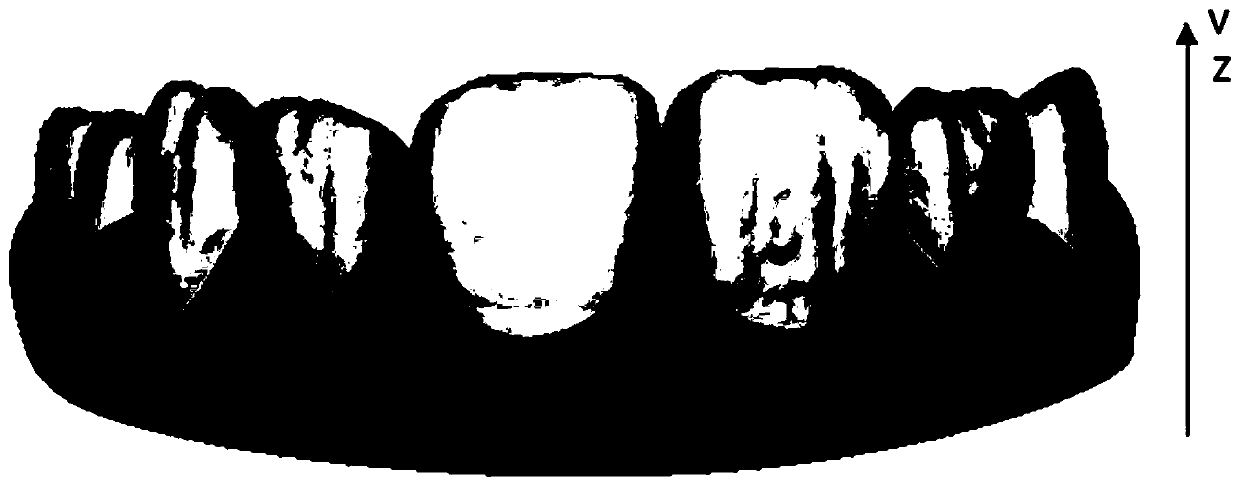

[0052] Secondly, import the digital tooth model into the 3D printer, and determine the direction of the Z axis such as figure 1 shown.

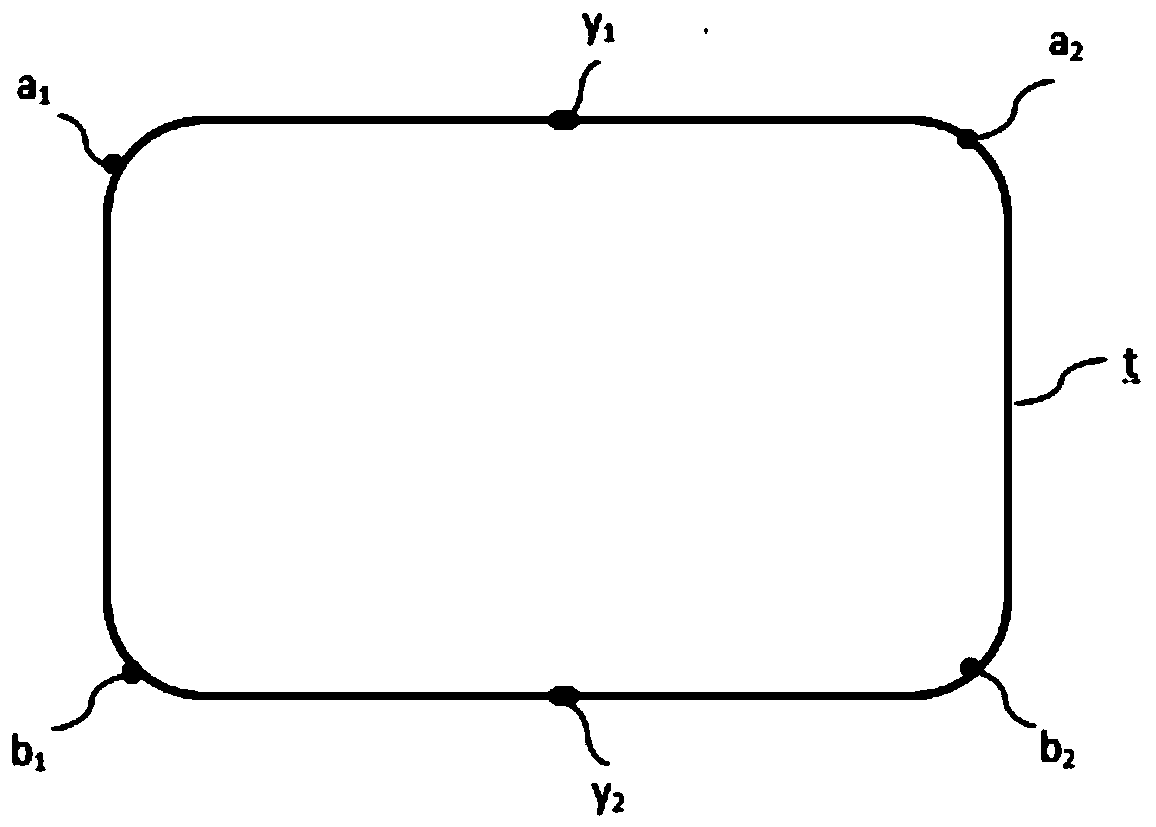

[0053] Such as figure 2 As shown, extract the feature points of each tooth: select buccal distal mastoid point a1, lingual distal mastoid po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com