Film-soil suspension separation mechanism

A technology of separation mechanism and membrane soil, which is applied in the direction of solid separation, separation of solids from solids by air flow, and filtration and sieving, which can solve the problems of incomplete separation of membrane soil, easy leakage of residual film, and aggravated pollution of residual film. , to achieve perfect equipment performance and solve the effect of not being easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

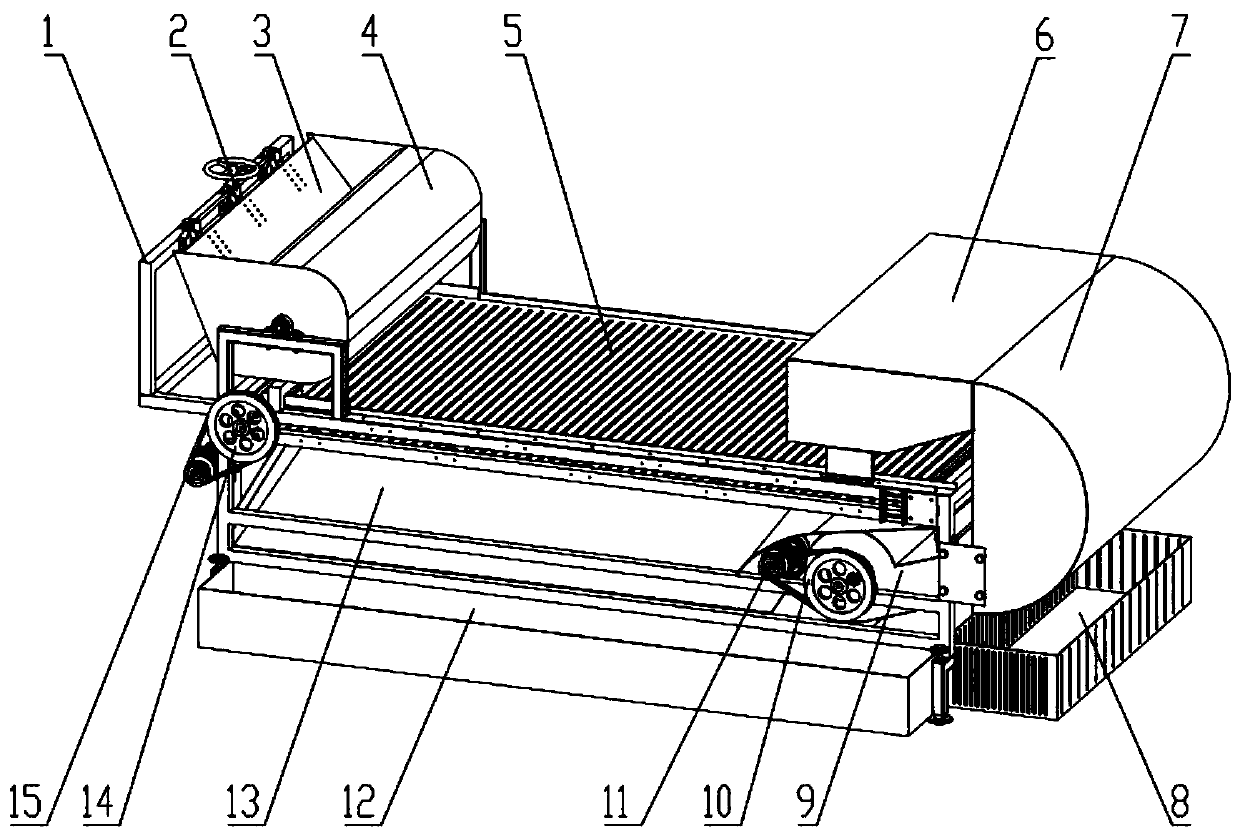

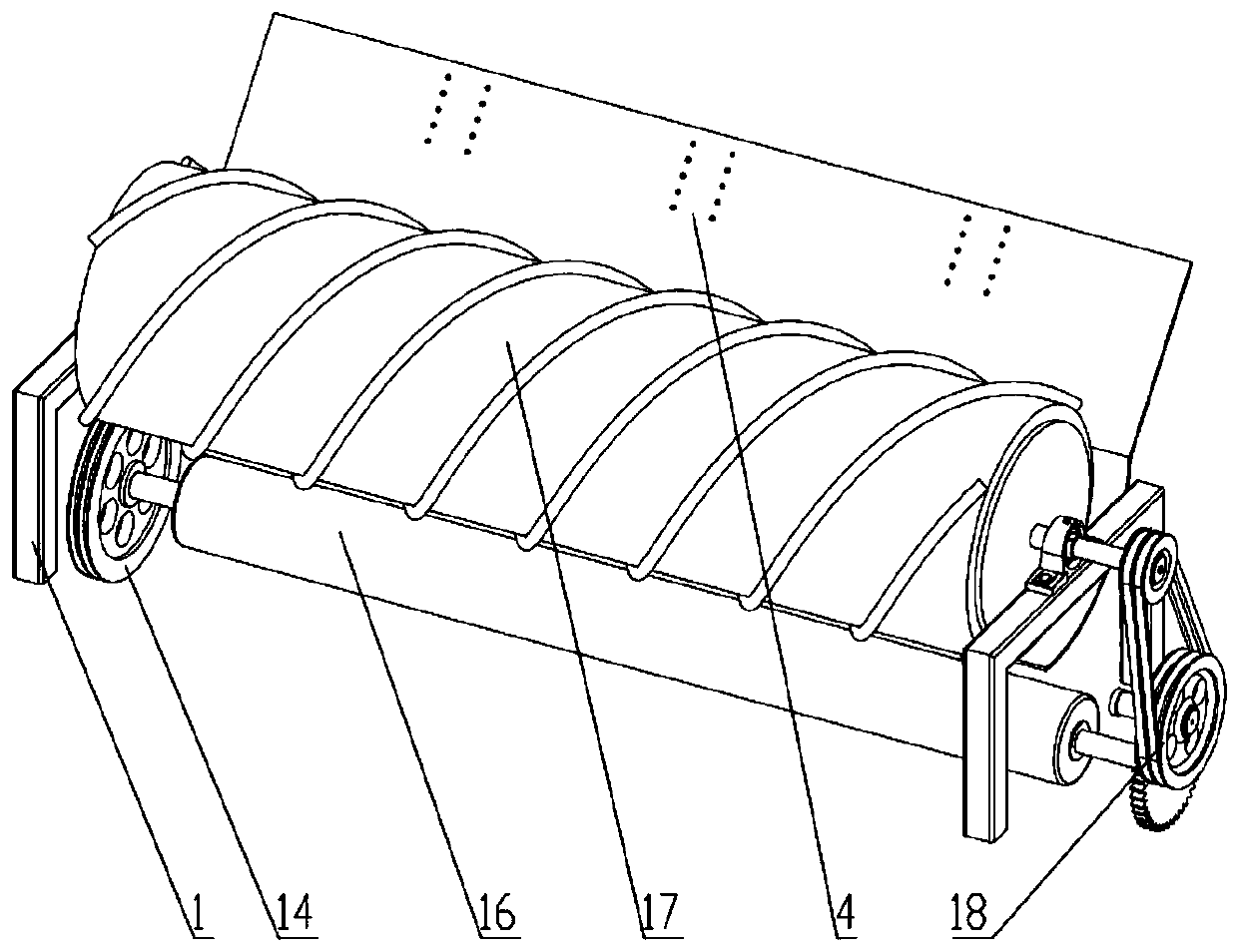

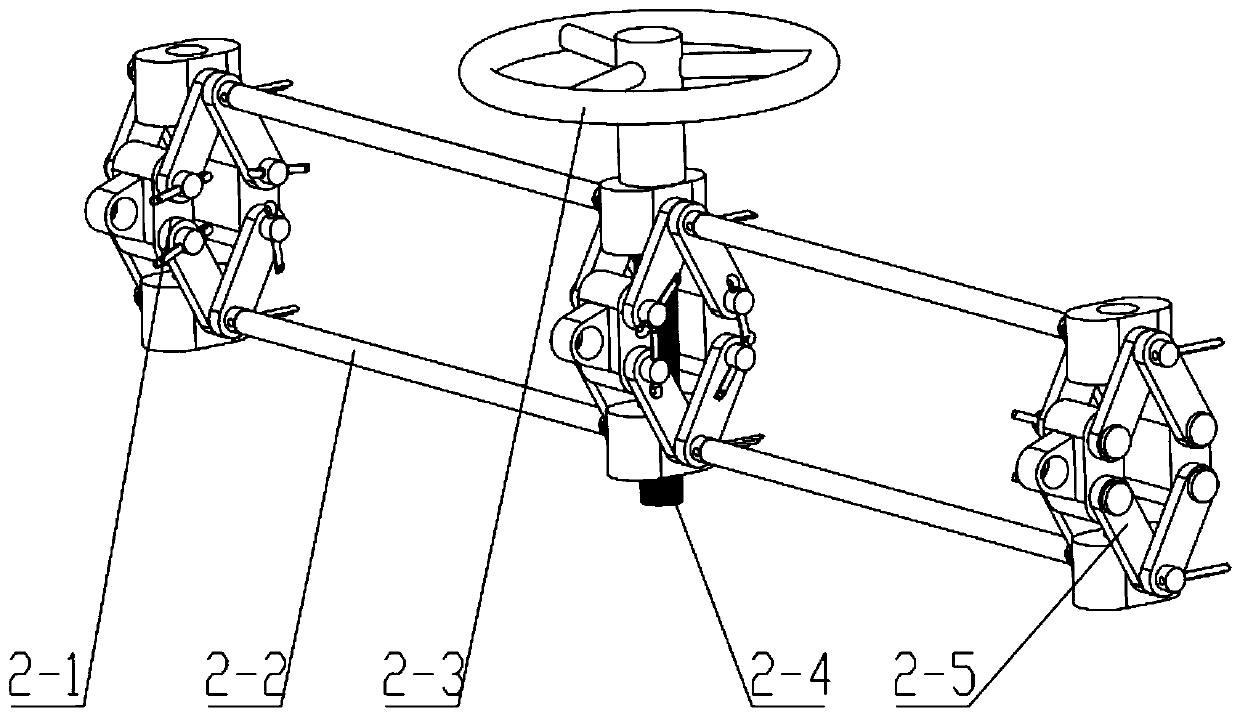

[0017] Such as Figure 1 to Figure 6 As shown, a membrane-soil suspension separation mechanism includes a frame 1 and a synchronous telescopic regulator

[0018] Structure 2, crushing concave plate 3, roller box 4, screen conveyor belt 5, film collecting box 6, air guiding device 7, soil collecting box Ⅰ 8, fan 9, fan power transmission mechanism 10, motor Ⅰ 11, soil collecting box Ⅱ 12, Soil collecting plate 13, conveyor belt power mechanism 14, motor II 15, guide roller 16, corrugated roller 17, roller power transmission mechanism 18, the frame 1 is the carrier of other parts, located at the bottom of the machine, the synchronous The telescopic adjustment mechanism 2 is installed and fixed on the frame 1 by bolts, and is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com