Centrifugal equipment for solid-liquid separation

A centrifugal equipment and solid-liquid separation technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of inability to achieve separation, low production efficiency, inconvenience, etc., to improve product production efficiency and increase outflow speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to illustrate the present invention in detail.

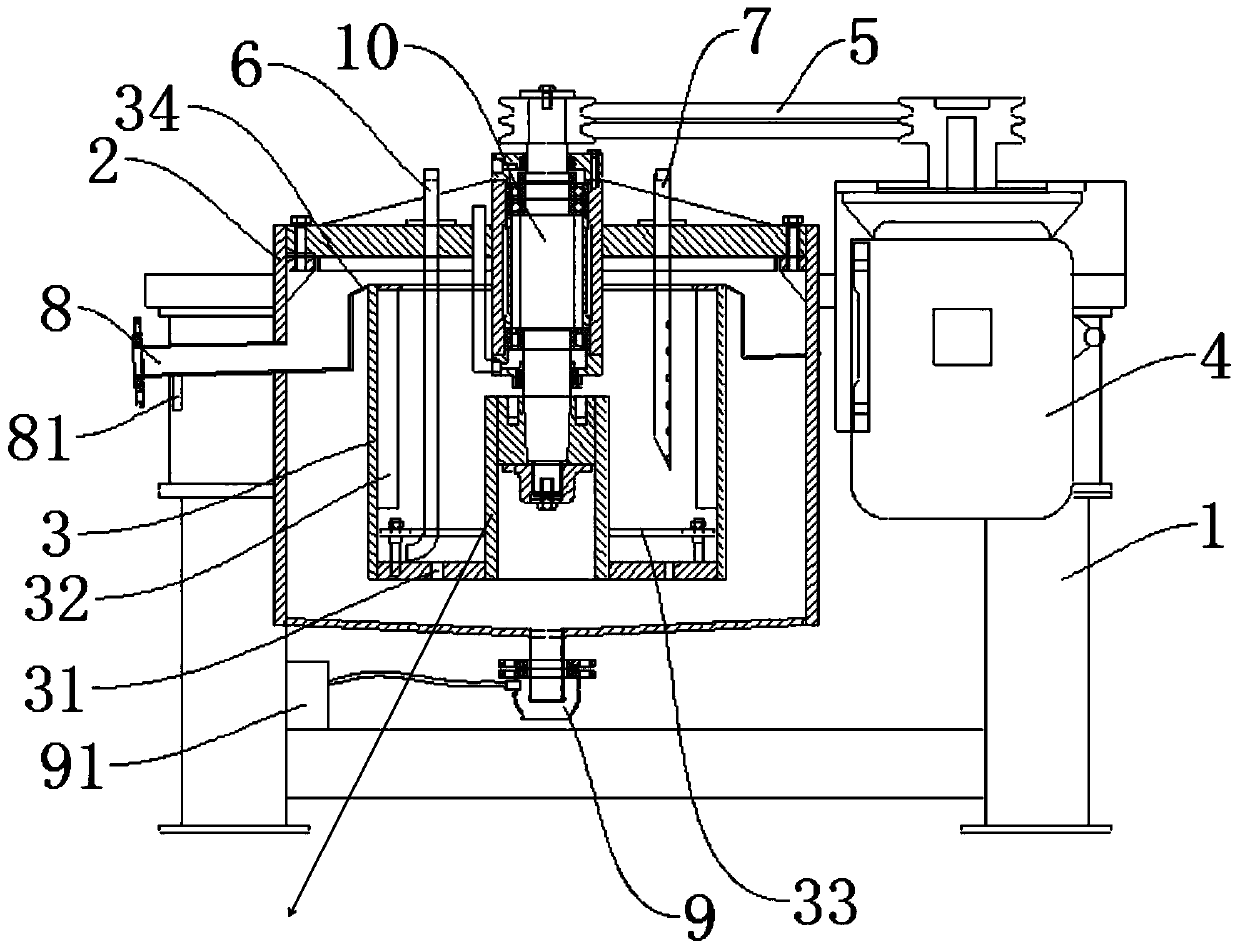

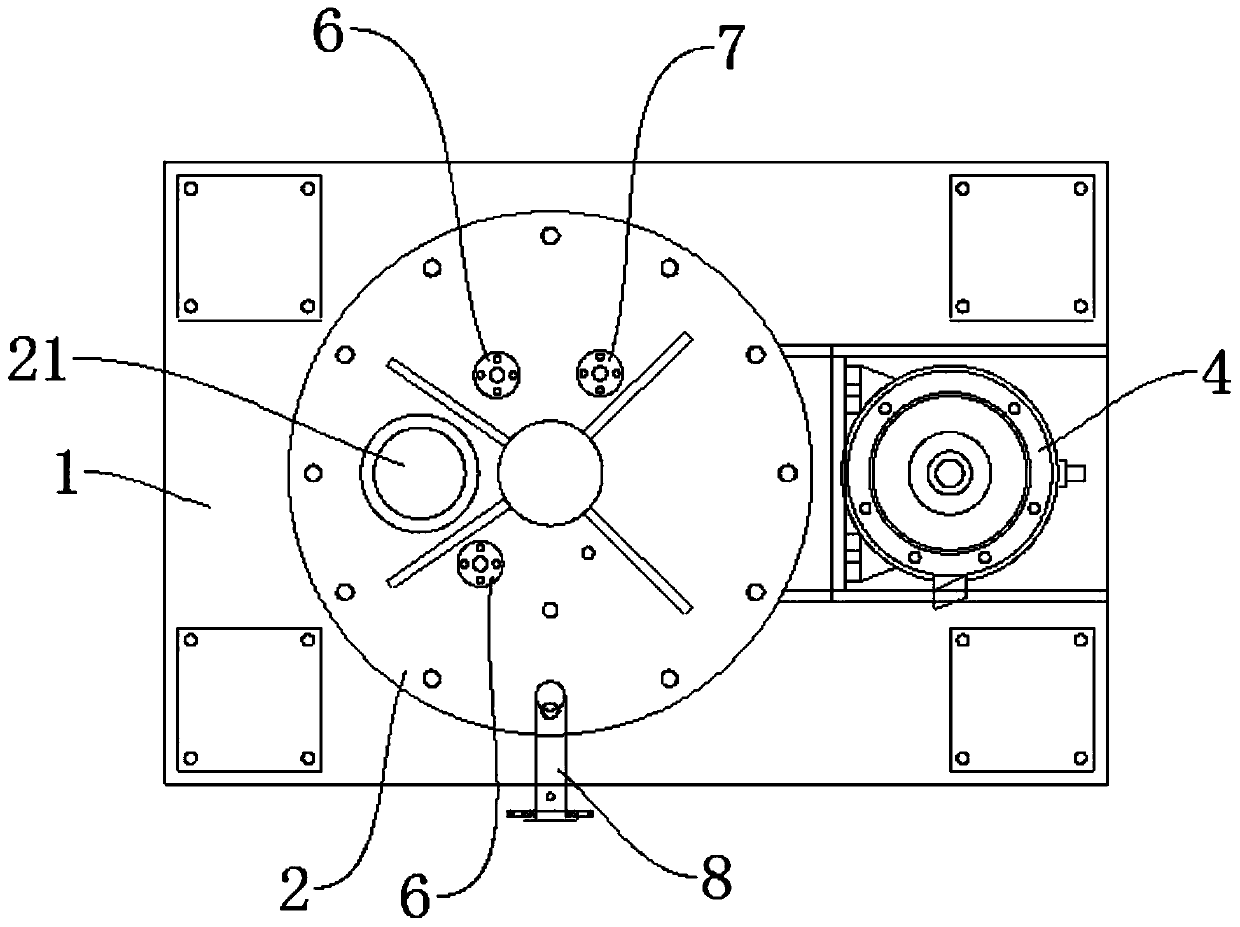

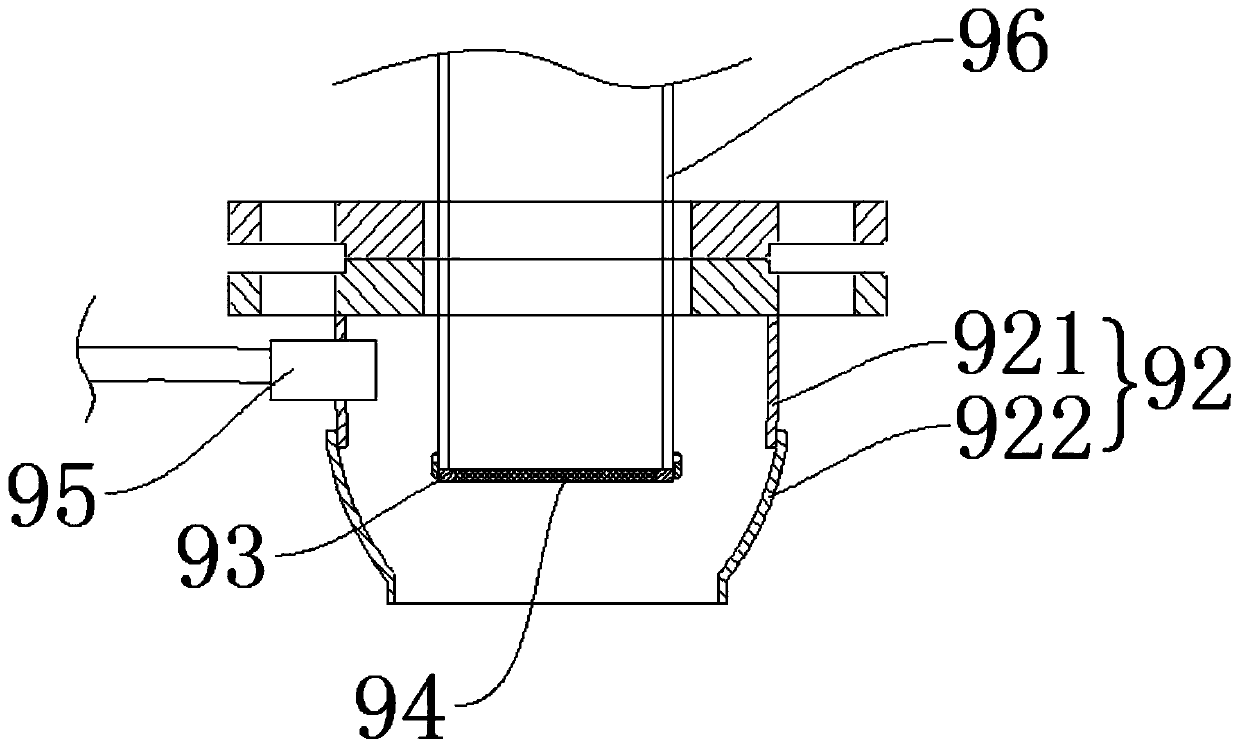

[0027] refer to Figures 1 to 3 As shown in , the centrifuge equipment for solid-liquid separation provided by the present invention includes a frame 1, a centrifuge outer casing 2 fixed on the frame 1 and a light liquid discharge pipe 8, and a centrifuge outer casing 2 inside Rotary drum 3, rotatable shaft 10 passing through the top cover of centrifuge outer shell 2 and fixedly connected with drum 3, feeding pipe 6 and washing pipe 7 extending into drum 3, fixed on drum 3 The drainage plate 32 on the inner wall, wherein,

[0028] A speed-regulating motor 4 is also installed on the frame 1, and the output shaft of the speed-regulating motor 4 is connected to the upper end of the rotating shaft 10 through a transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com