Automatic screw machine with three degrees of freedom

A screw machine, a degree of freedom technology, used in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of misalignment, skew, slip, etc., to achieve the effect of fast screwing, simple use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

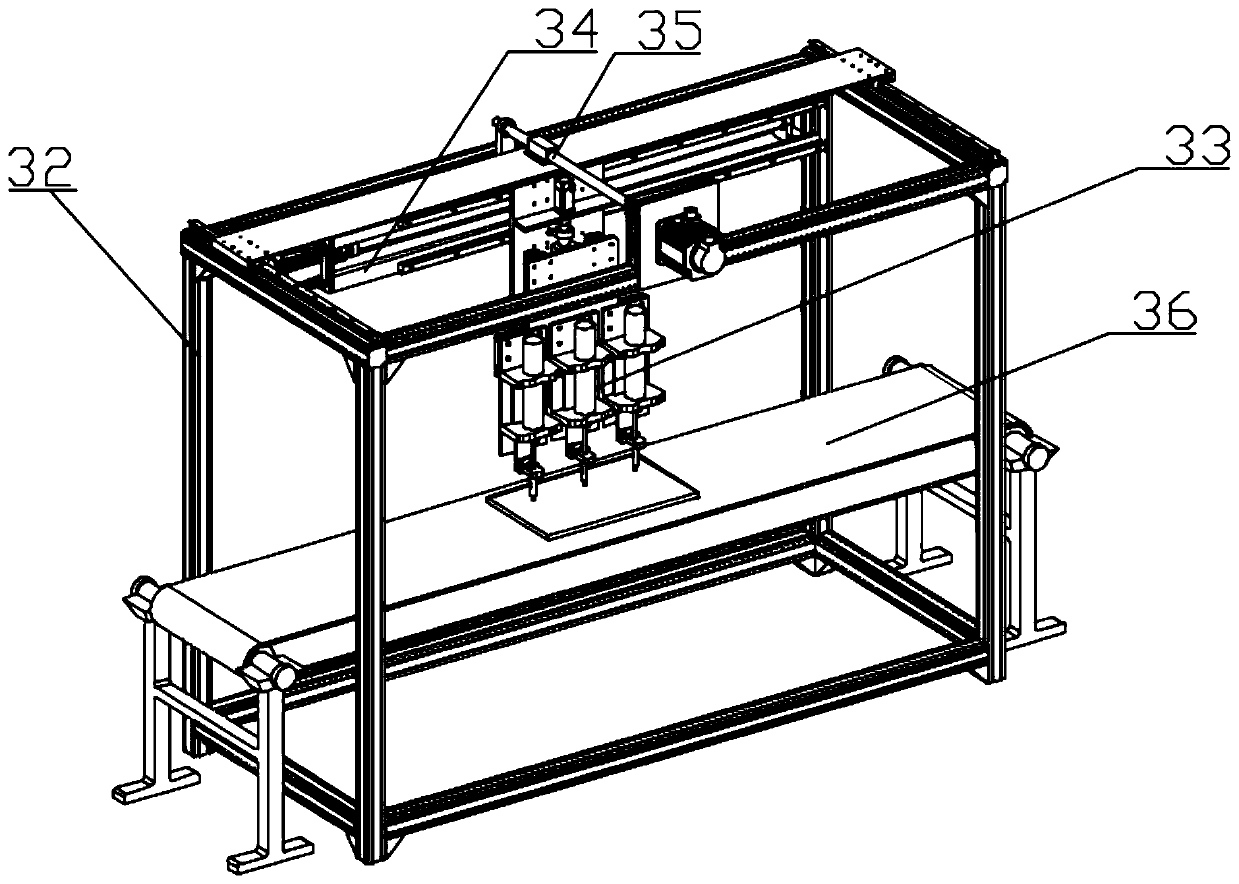

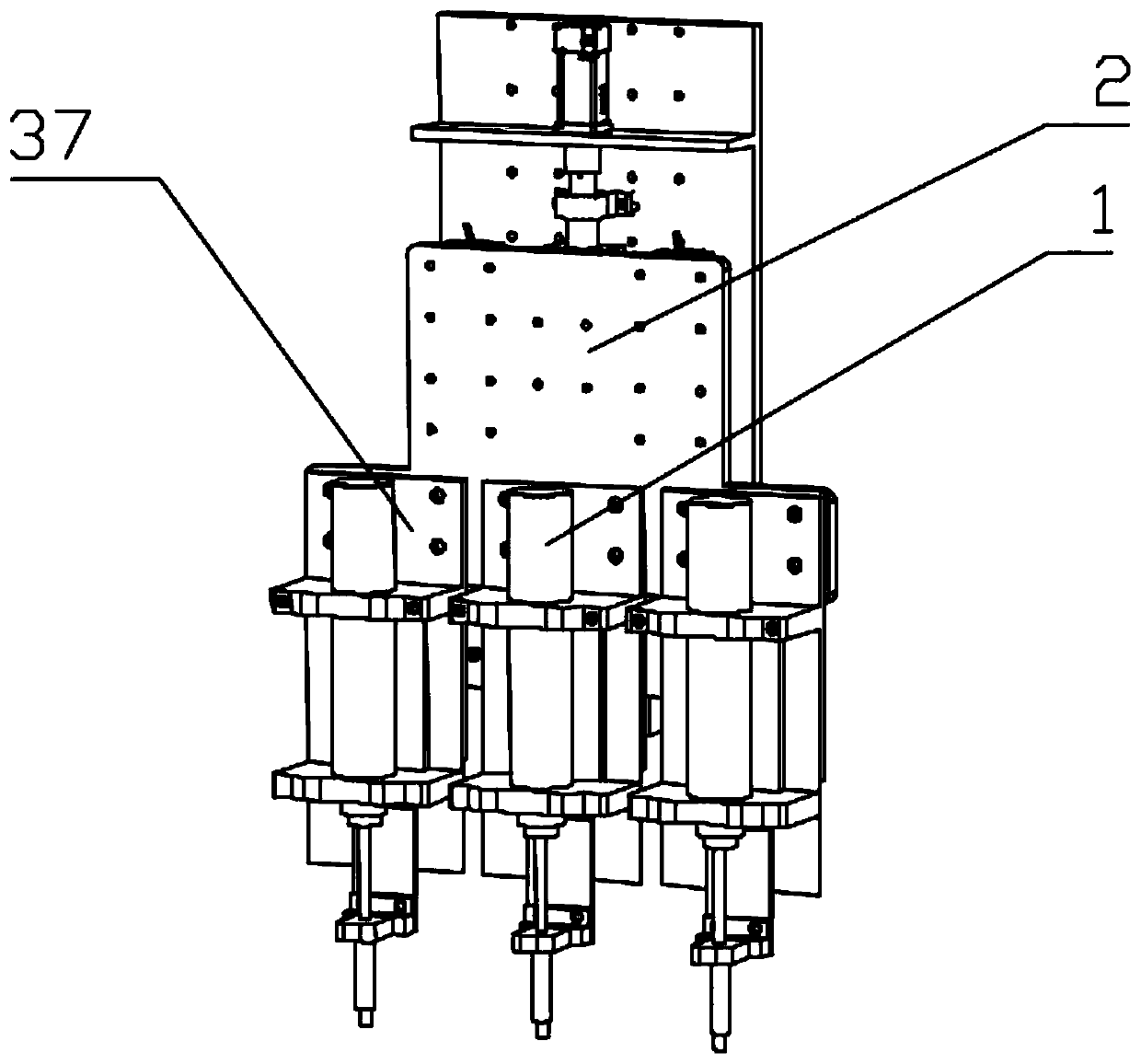

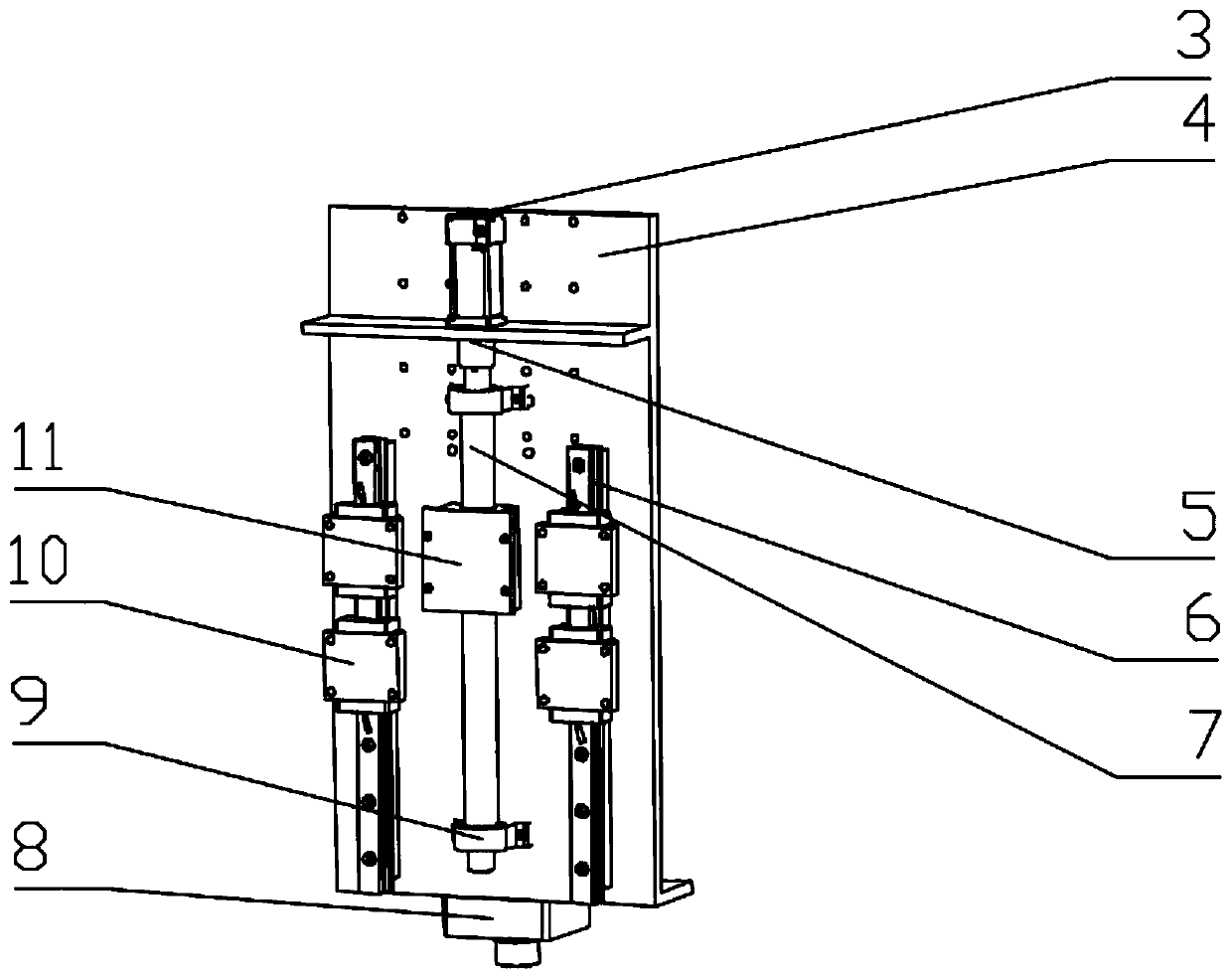

[0022] Embodiment 1: as Figure 1-Figure 8 As shown, a three-degree-of-freedom automatic screw machine includes a screw machine positioning control mechanism 33, an X-axis transmission system 34, a Y-axis transmission system 35, and a workbench 36; the screw machine positioning control mechanism 33 is used to drive and install The screw electromechanical batch 1 on the screw machine positioning control mechanism 33 moves along the Z direction; the X-axis transmission system 34 is used to drive the screw machine positioning control mechanism 33 to move along the X direction; the Y-axis transmission system 35 is used for Drive the positioning control mechanism 33 of the screw machine to move along the Y direction; the workbench 36 is used to transfer the screw parts to be driven.

[0023] Further, the X-axis transmission system 34 can be set to drive the screw machine positioning control mechanism 33 installed on the X-axis transmission system 34 to move along the X direction; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap