Method for installing and detecting lifting flipper guide rail

A detection method and a technology of lifting fins, which are applied in the directions of measuring devices, transportation and packaging, and mechanical devices, etc., can solve the problems of low precision, low time-consuming efficiency of measurement methods, etc., and achieve less time-consuming, improved accuracy and efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below with reference to the accompanying drawings.

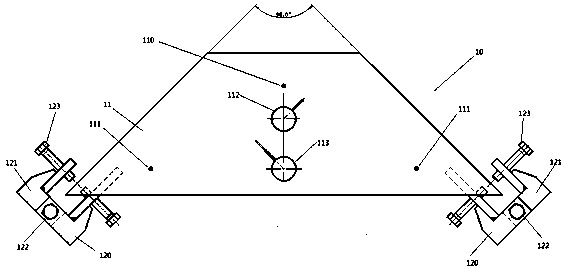

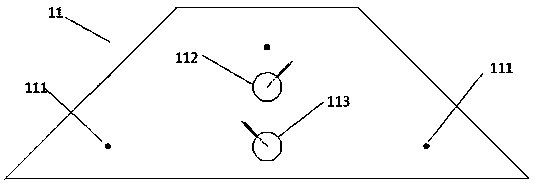

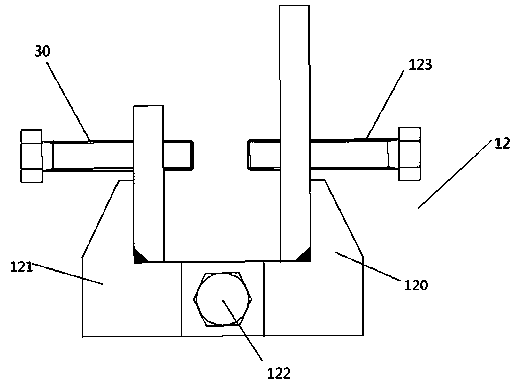

[0051] Refer to attached figure 1 - attached Figure 22 ,

[0052] A method for installing and detecting a lifting fin guide rail, comprising the following steps:

[0053] First, check the data of the surrounding well 50. The surrounding well 50 is spliced by different segments. Check whether the accuracy and length of these segments are within the range of error requirements. 51 is marked and fixed on the inner wall of the well 50 by spot welding. Between the support plates 51, steel pipes or angle steels are used to ensure the relative distance between the support plates, and the distance between the support plates and the ship’s reference line is measured. Whether the difference between the actual value and the design value is between -2mm and 0mm, within the error range, the support plate 51 is welded and fixed on the inner wall of the enclosure 50;

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com