Mine intrinsic safety type camera

An intrinsically safe camera technology, applied in the field of cameras, can solve problems such as waste of resources, inconvenient observation and repair, and small internal space of the camera, and achieve the effects of reducing difficulty, facilitating manual replacement and repair, and facilitating observation and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

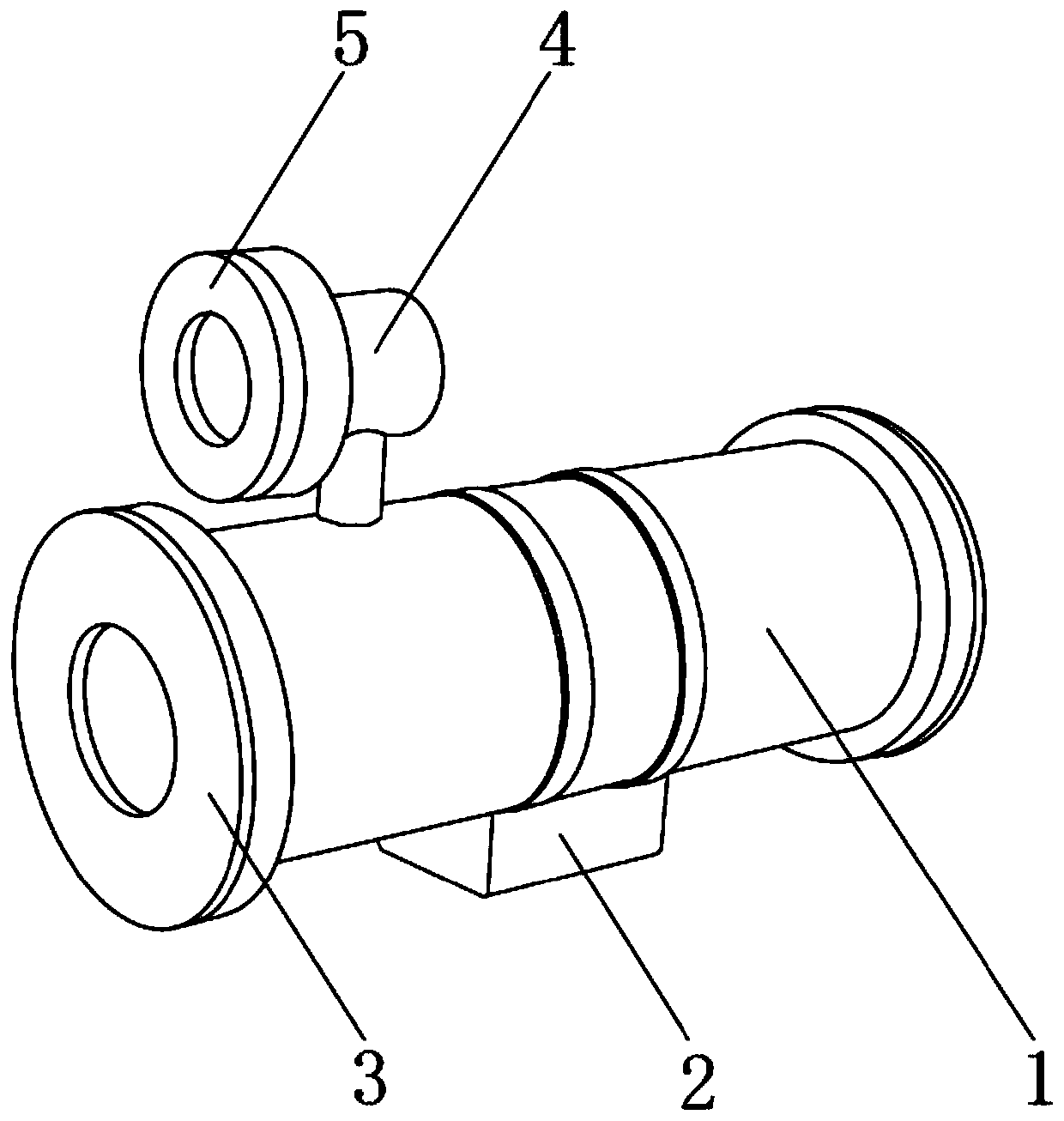

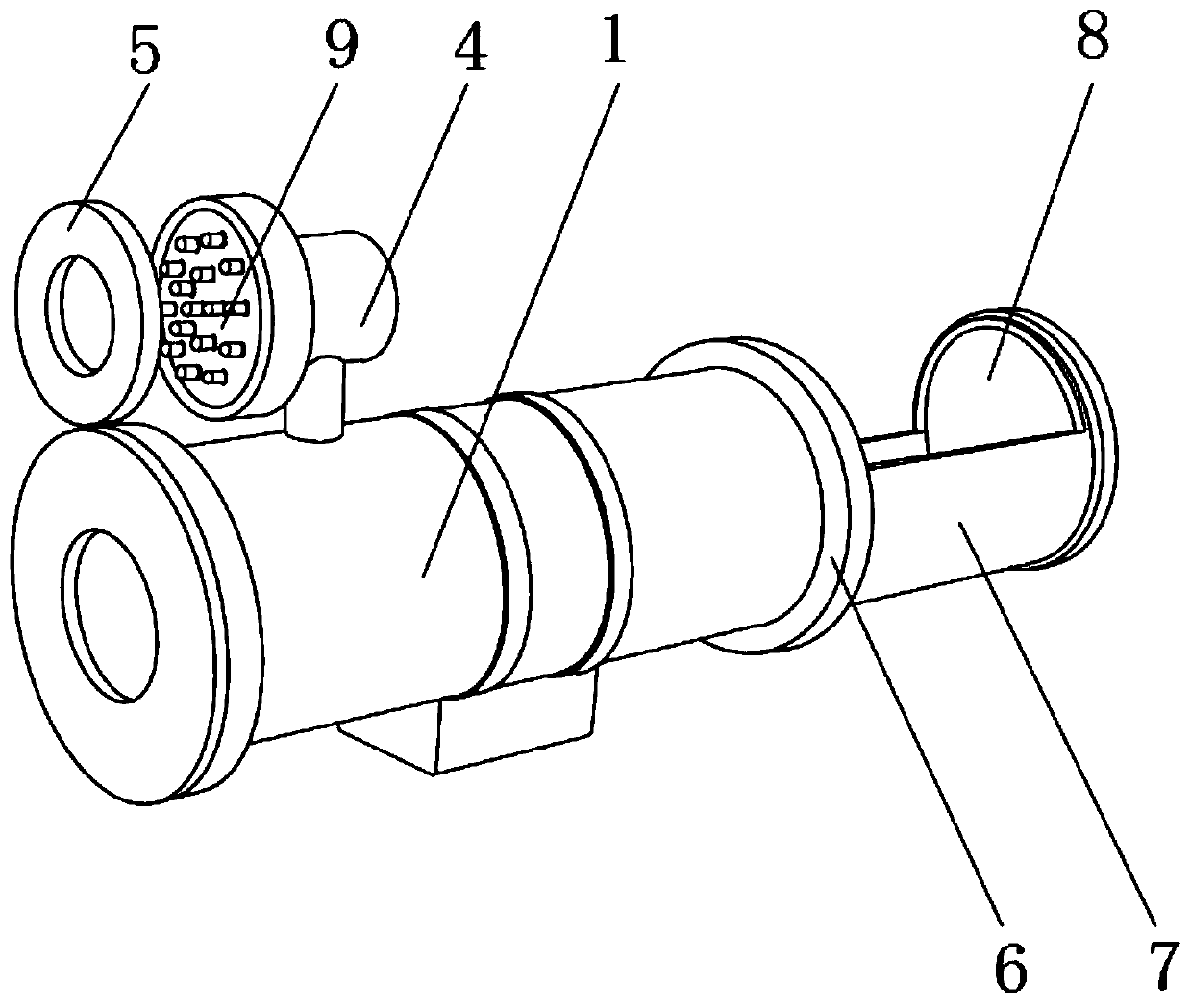

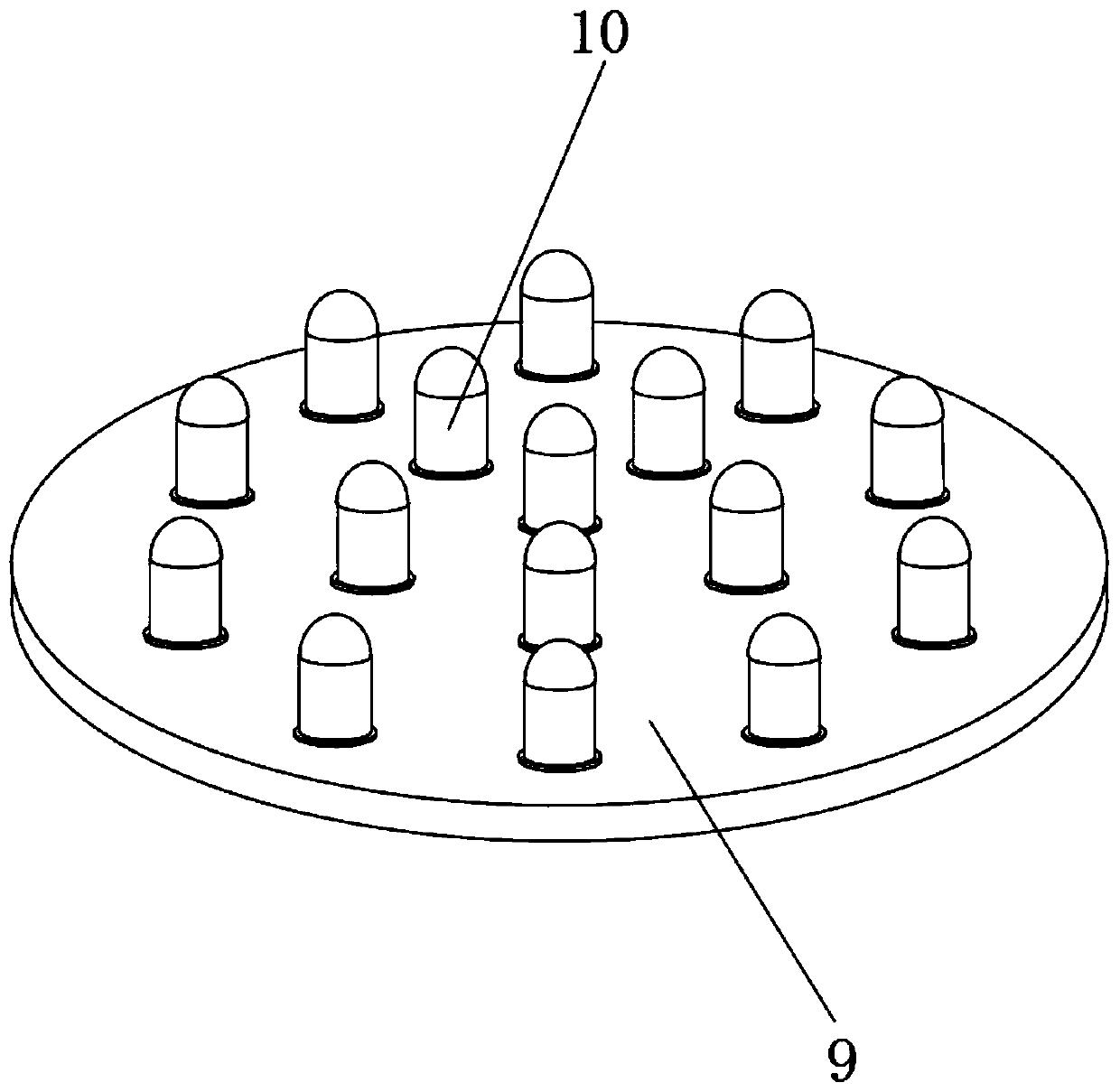

[0024] refer to Figure 1-2 As shown, a mining intrinsically safe camera includes a camera tube 1, the outer surface of the camera tube 1 is fixed with a control box 2 through a throat clamp near the bottom end, and the front end outer surface of the camera tube 1 is welded with a front fixing ring 3 , and the inner center of the front fixing ring 3 is bonded with a lens near the front end, the outer surface of the front end of the front fixing ring 3 near the lens is fixed with a dust-proof net by bolts, and the outer surface of the top of the camera 1 is welded near the front end There is a lamp tube 4, and the outer surface of the front end of the lamp tube 4 is fixed with a lampshade 5 by bolts, the outer surface of the rear end of the camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com