Assembly structure of decorative plate assembly and end cover, decorative plate assembly and air conditioner

A technology for assembling structures and decorative panels, applied in the directions of heating and ventilation hoods/covers, etc., can solve the problems of deformation of decorative panel components, difficult to apply force, and movement of air conditioners, and achieve the effect of easy disassembly, easy application, and improved assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

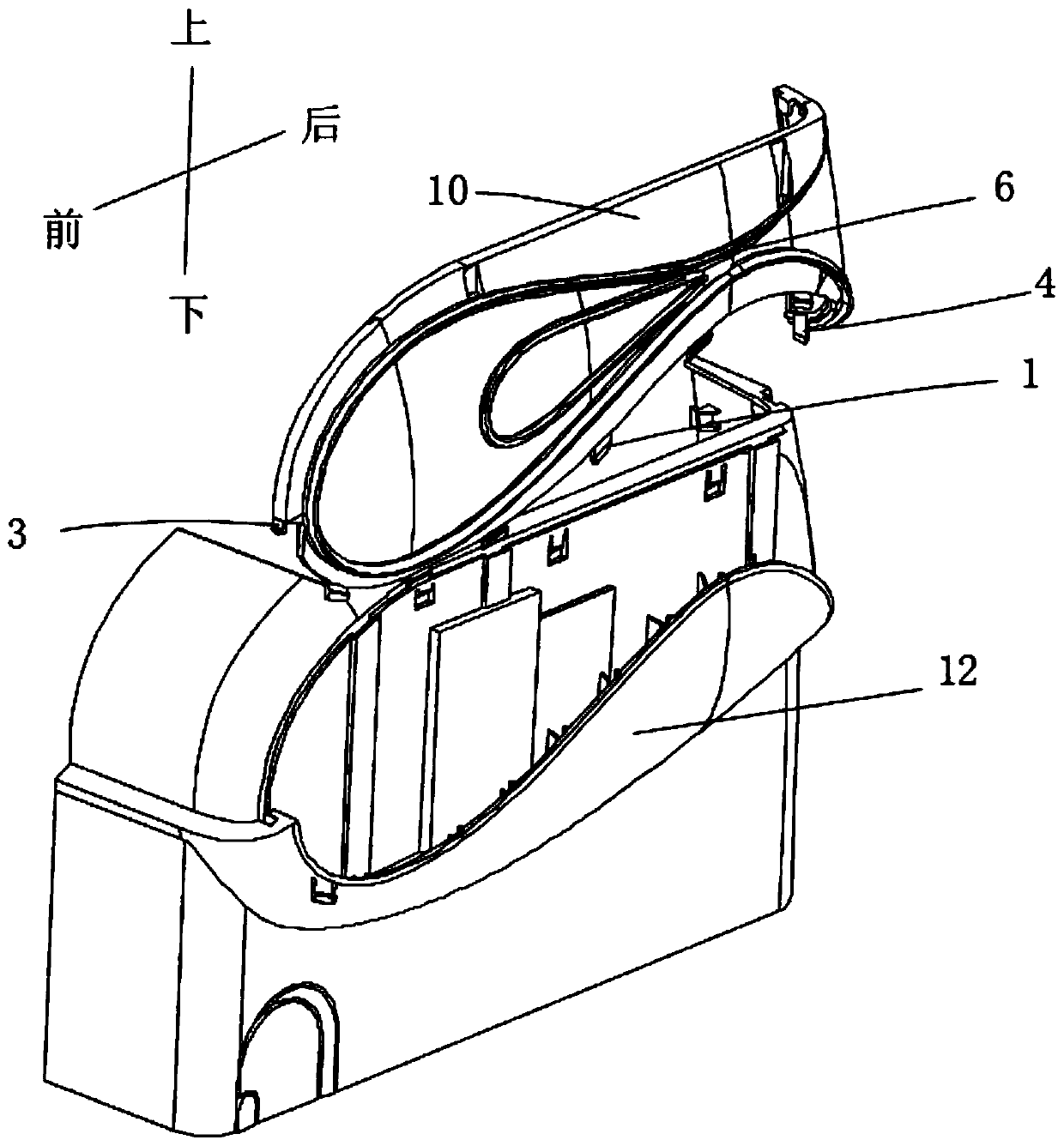

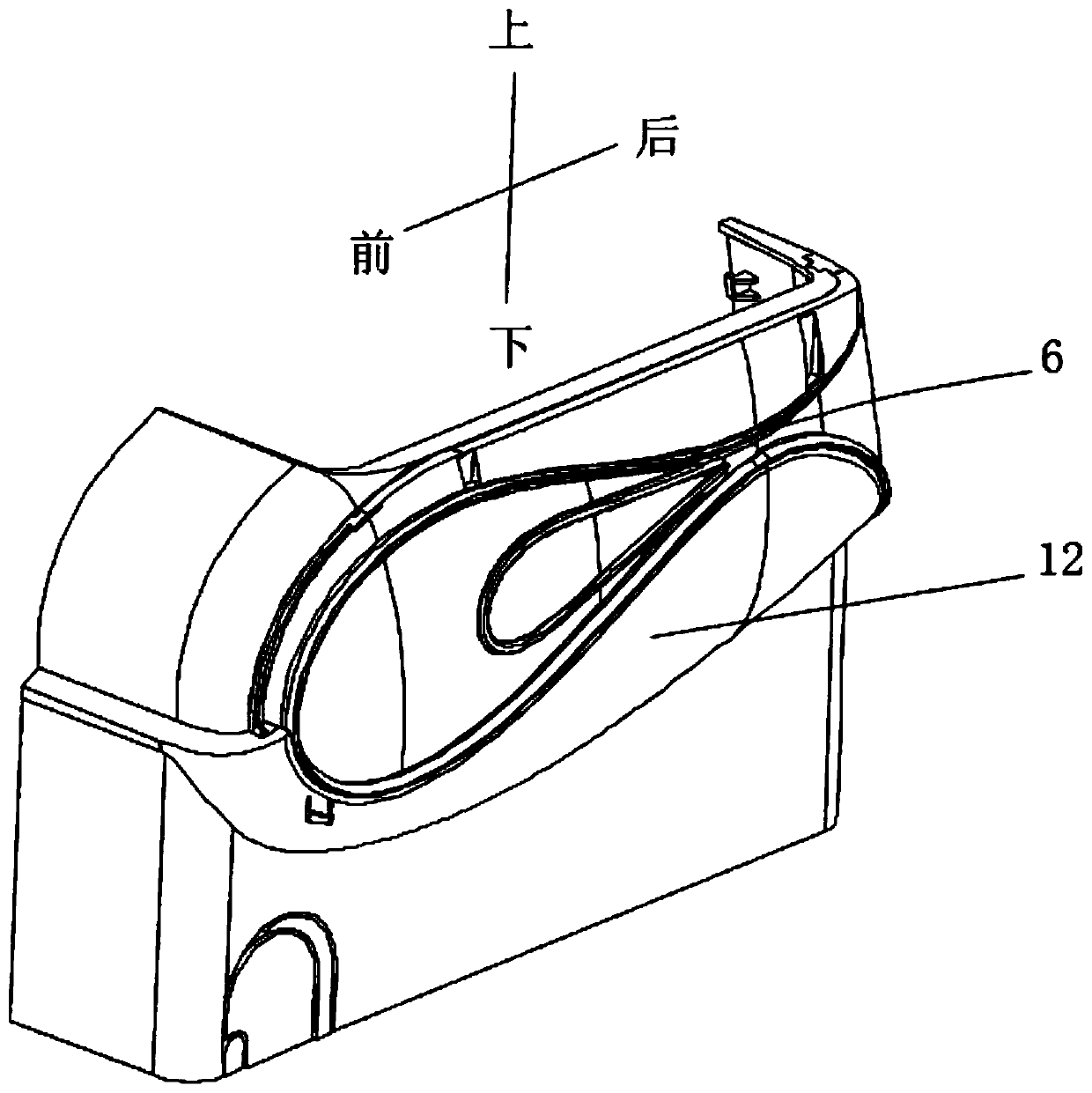

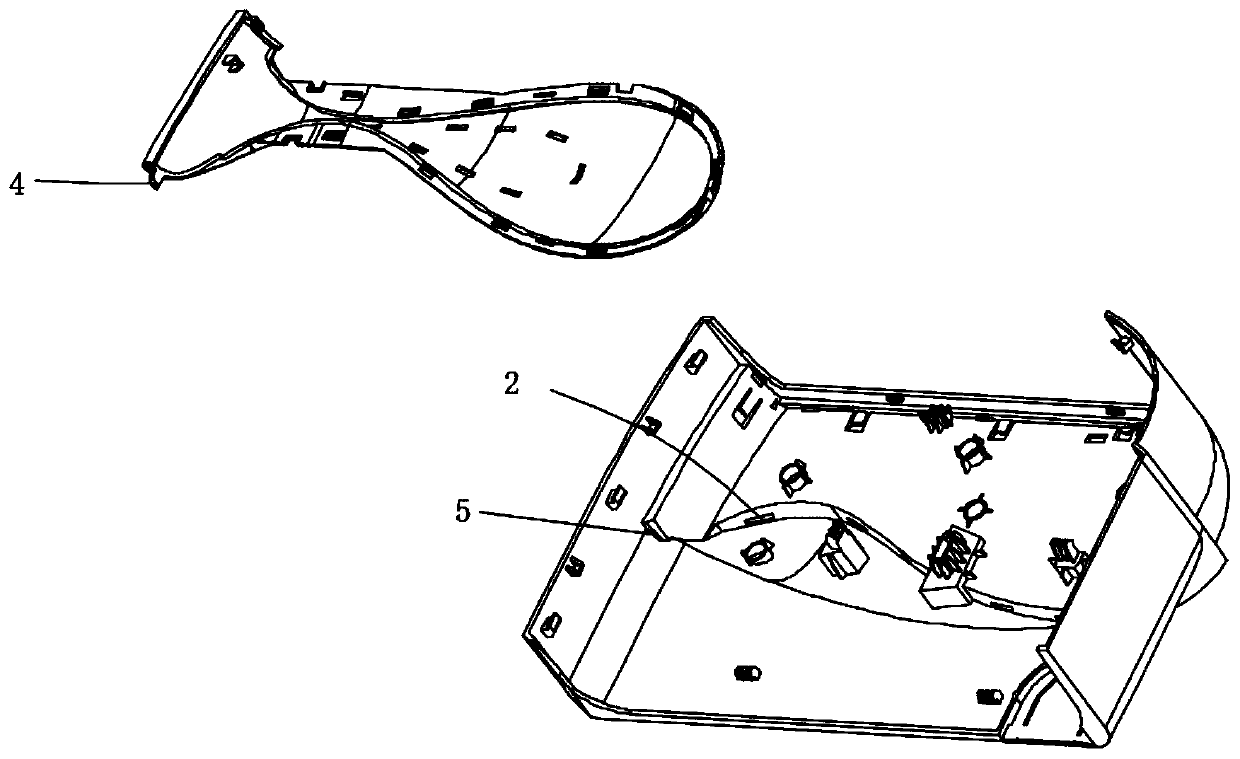

[0047] In the air conditioner assembly process, the air conditioner is usually placed flat on the workbench, and then the parts are assembled. The existing decorative panel assembly is usually assembled with the end cover of the air conditioner in the horizontal direction. The length is large, and it is difficult for the staff to hold and fix it. During the installation process, the staff manually squeezes the side of the decorative panel assembly laterally in the horizontal direction, so that the decorative panel assembly is clamped on the end cover, and it is not easy to apply force. Due to the decorative panel assembly and The end covers are generally connected by multiple buckle structures. In the process of extrusion and clamping, a large force of extrusion is required to complete the assembly between the decorative panel assembly and the end cover. The air conditioner is subjected to a large force in the horizontal direction. If the movement occurs, it is easy to cause th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com