Asymmetric blasting method for dismantling milling coal hole sleeve

A coal-slipping and asymmetric technology is applied in the field of asymmetric blasting for removing coal-slipping sleeves, and achieves the effects of saving manpower, improving work efficiency, and having obvious safety effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] An asymmetric blasting method for removing a coal chute sleeve, comprising the following steps:

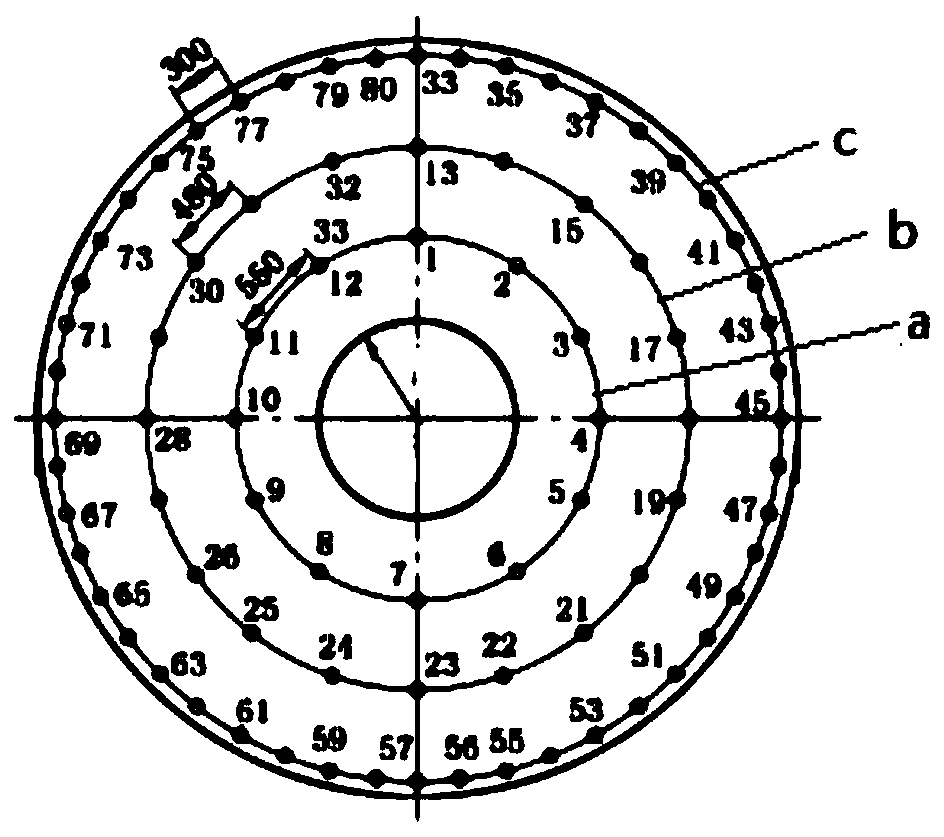

[0027] (1) Three layers of blasting rings are arranged in sequence along the outer circumference of the coal hole sleeve, which are the first layer of blasting rings, the second layer of blasting rings and the third layer of blasting rings, and the first layer of blasting rings is equidistant counterclockwise The blastholes numbered 1-12 are arranged in order, the blastholes numbered 13-32 are arranged in an equidistant counterclockwise order on the second layer of blasthole ring, and the numbers 33-80 are arranged in an equidistant counterclockwise order on the third layer of blasthole ring Among them, the blastholes No. 1-32 are auxiliary blastholes, and the blastholes No. 33-80 are peripheral holes; the depth of the blasthole is required not to be lower than the joint of two adjacent sleeves, and the depth of the blasthole is too shallow or too deep It will cause the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com