Error-proofing detection method for PLG brake assembly

A technology of brake components and detection methods, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to guarantee the quality of finished products, low equipment output rate, and high personnel investment, so as to improve quality, avoid misjudgments and misjudgments, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

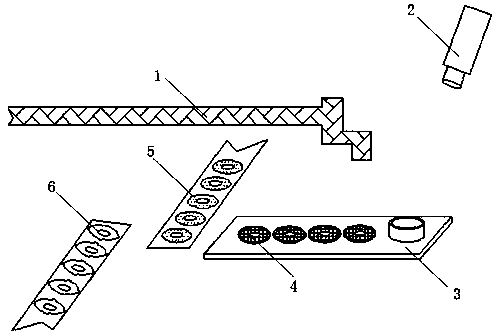

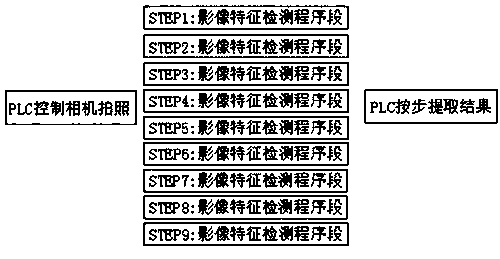

[0012] Such as figure 1 and figure 2 As shown, the error-proof detection method of a PLG brake assembly in this embodiment includes the following steps: S100) Grab the parts by the mechanical gripper 1, pick and place one part at a time, and set each pick and place as a step ; S200) After the parts are placed, control the smart camera 2 to take pictures; S300) The smart camera presets multiple recognition program segments, and each program segment only judges whether the parts photographed by the camera are what should be in the current step Parts; S400) The smart camera is controlled by the PLC processor. In the above technical solution, according to different steps, the PLC processor takes the result value of the corresponding program segment in the smart camera to judge whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com