Ultra-compact semi-direct-drive multistage planetary wind power gear box structure

A wind power gearbox and planetary gear transmission technology, applied in wind power generation, gear transmission, belt/chain/gear and other directions, can solve the problems of high cost of the whole machine, large load of the transmission chain tower, long axial direction, etc. The effect of reducing the cost of the main engine, improving the reliability, and reducing the length of the gearbox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

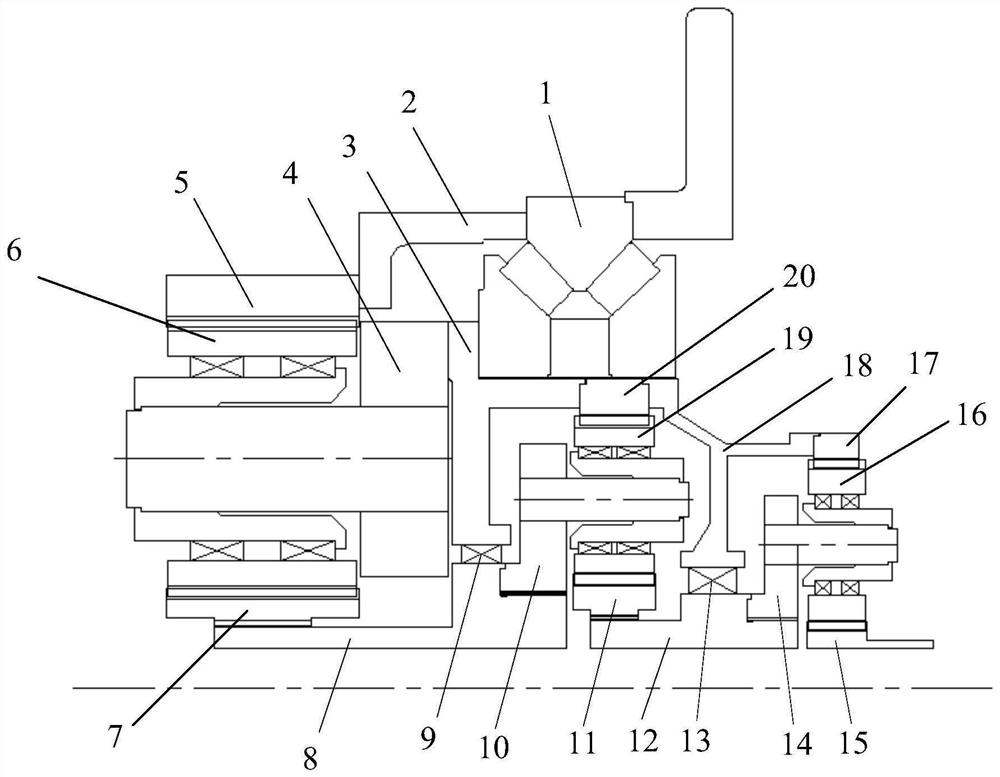

[0017] The present invention will be further described below in conjunction with specific examples.

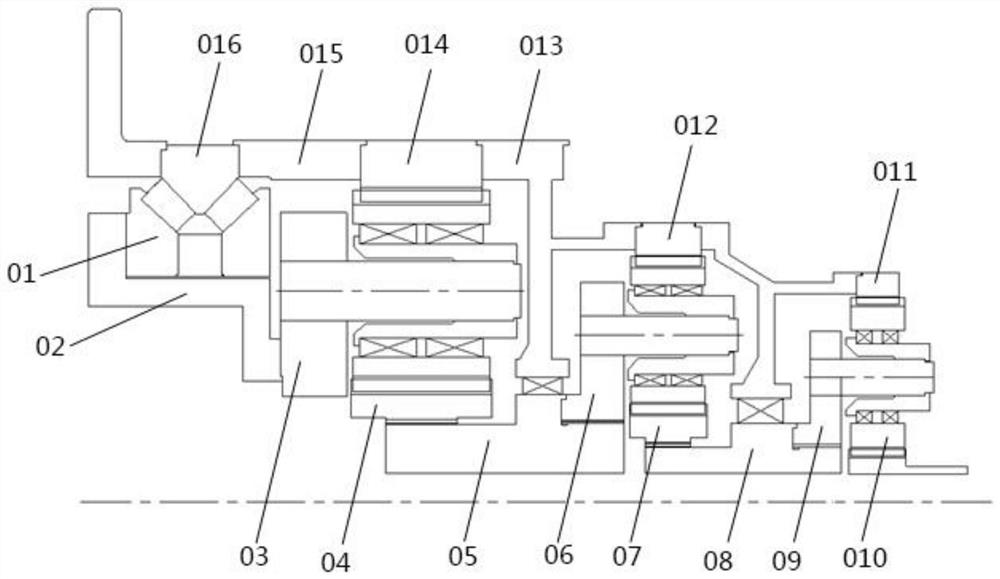

[0018] see figure 2 As shown, the structure of the ultra-compact semi-direct drive multi-stage planetary wind power gearbox provided in this embodiment includes a gearbox case, a main bearing 1, a primary flange 2 and a three-stage planetary gear transmission system;

[0019] The gearbox casing includes a second-stage casing 3 and a third-stage casing 18, the first-stage planetary gear transmission system is arranged inside the hub (not shown in the figure) of the wind turbine, and the second-stage The planetary gear transmission system is set at the inner hole of the main bearing 1, the outer ring of the main bearing 1 is respectively connected with the first-stage flange 2 and the hub system of the wind turbine, and the inner ring of the main bearing 1 passes through the second-stage box The body 3 is connected and fixed with the first-stage planet carrier 4 of the first-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com