Electric power iron tower

A technology for electric power towers and tower foundations, applied in the field of electric power towers, can solve problems such as low failure efficiency of iron towers, and achieve the effects of improving power generation efficiency, avoiding losses, and reducing its own temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

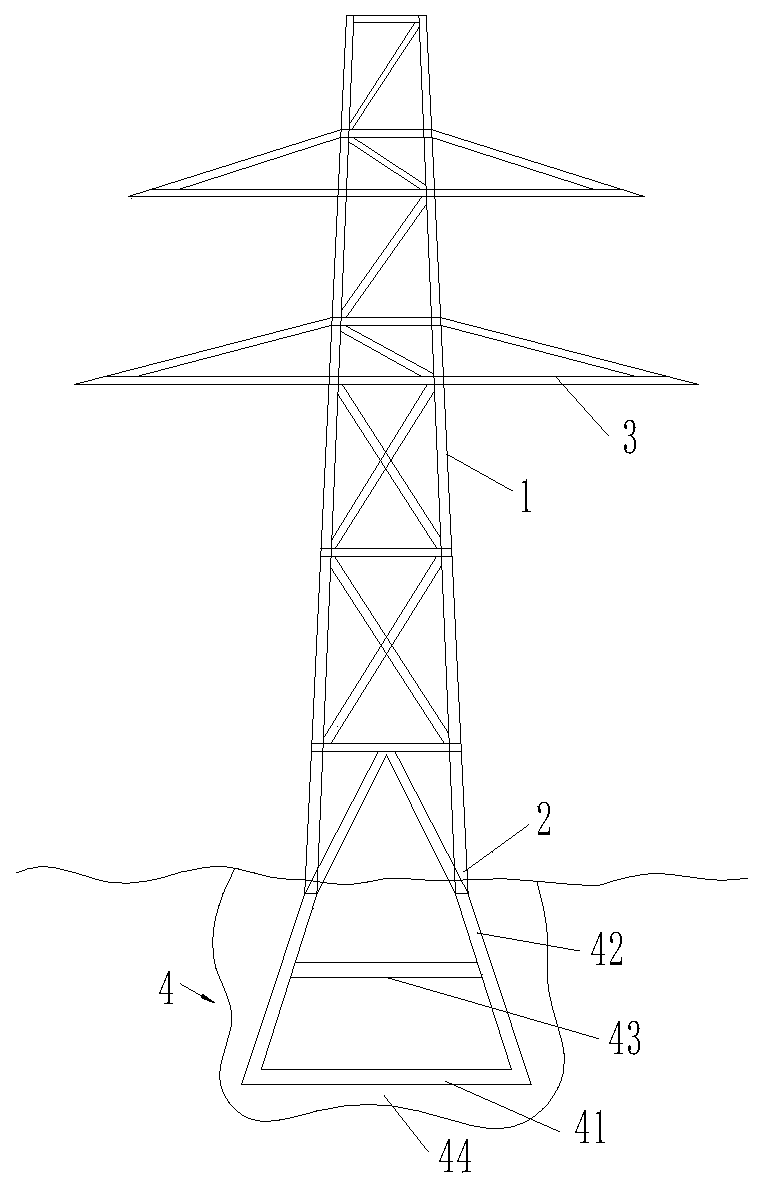

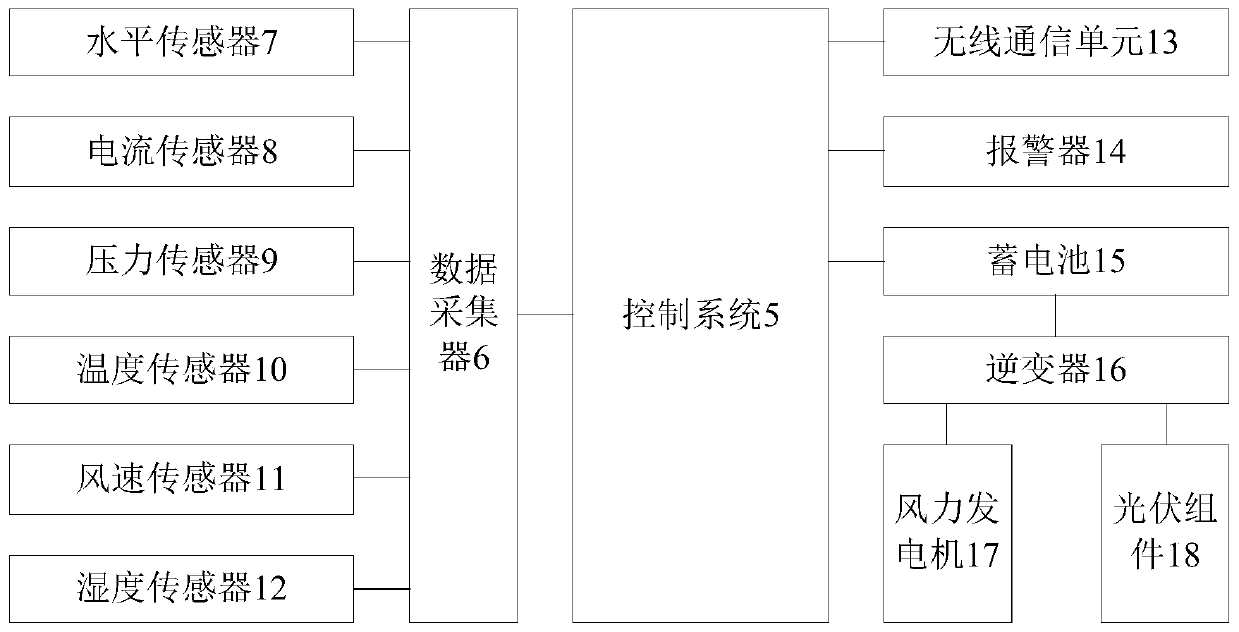

[0036] like figure 1 As shown, the power iron tower in this embodiment includes: iron tower base connection block 4, tower body 1, level sensor 7, current sensor 8, pressure sensor 9, temperature sensor 10, wind speed sensor 11, humidity sensor 12, data collector 6. Control system 5, wireless communication unit 13, alarm 14 and solar power generation device.

[0037] continue to refer figure 1 The iron tower foundation connecting block 4 includes a connecting frame and a prefabricated concrete block 44 that is coagulated onto the connecting frame. The connecting frame includes: a bottom plate 41 , an oblique support rod 42 and a horizontal support rod 43 . One end of four oblique support rods 42 is fixed on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com