Contactor

A contactor and moving contact technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of affecting service life, complex structure, large wear, etc., to extend service life, improve reliability, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

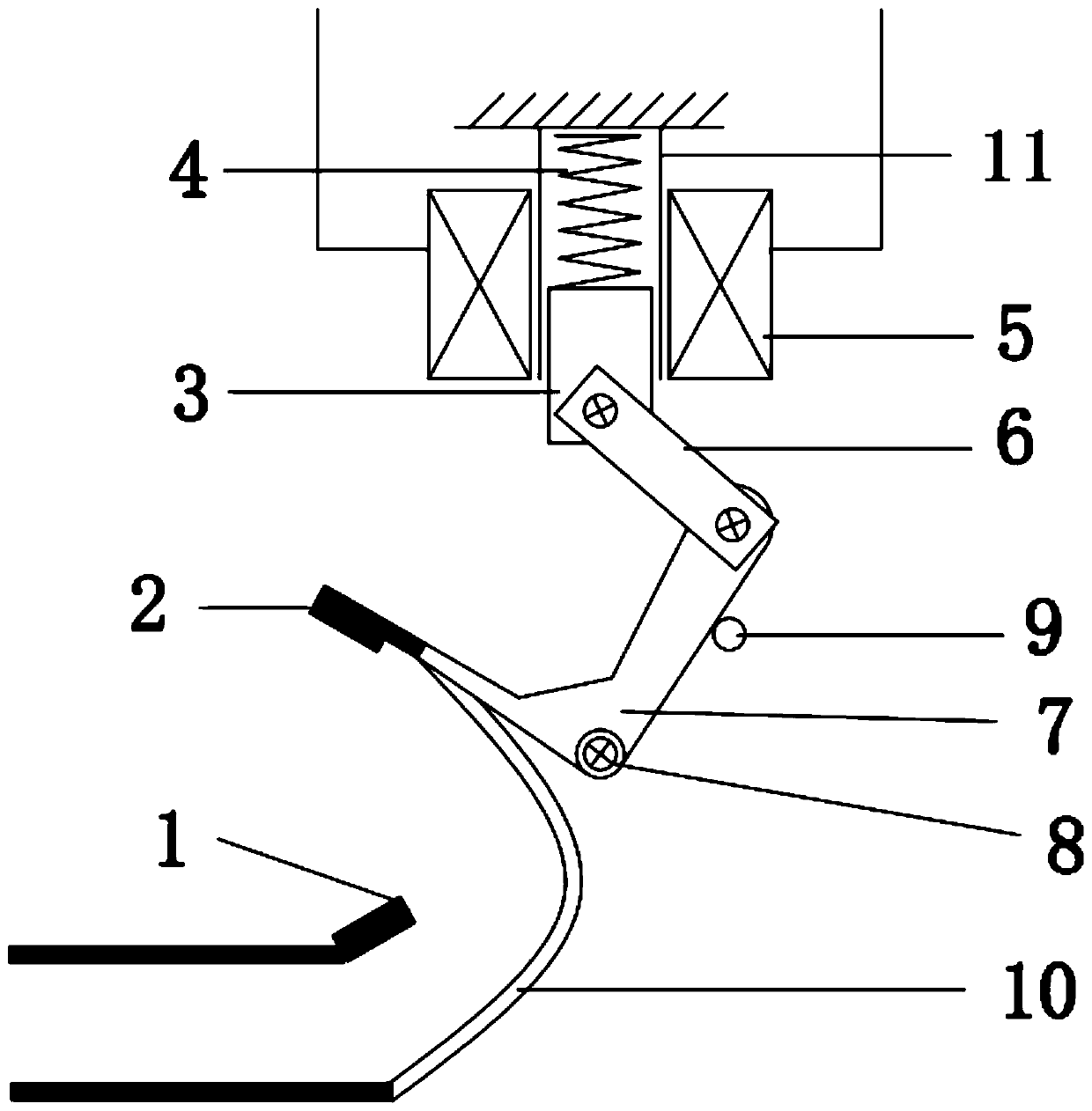

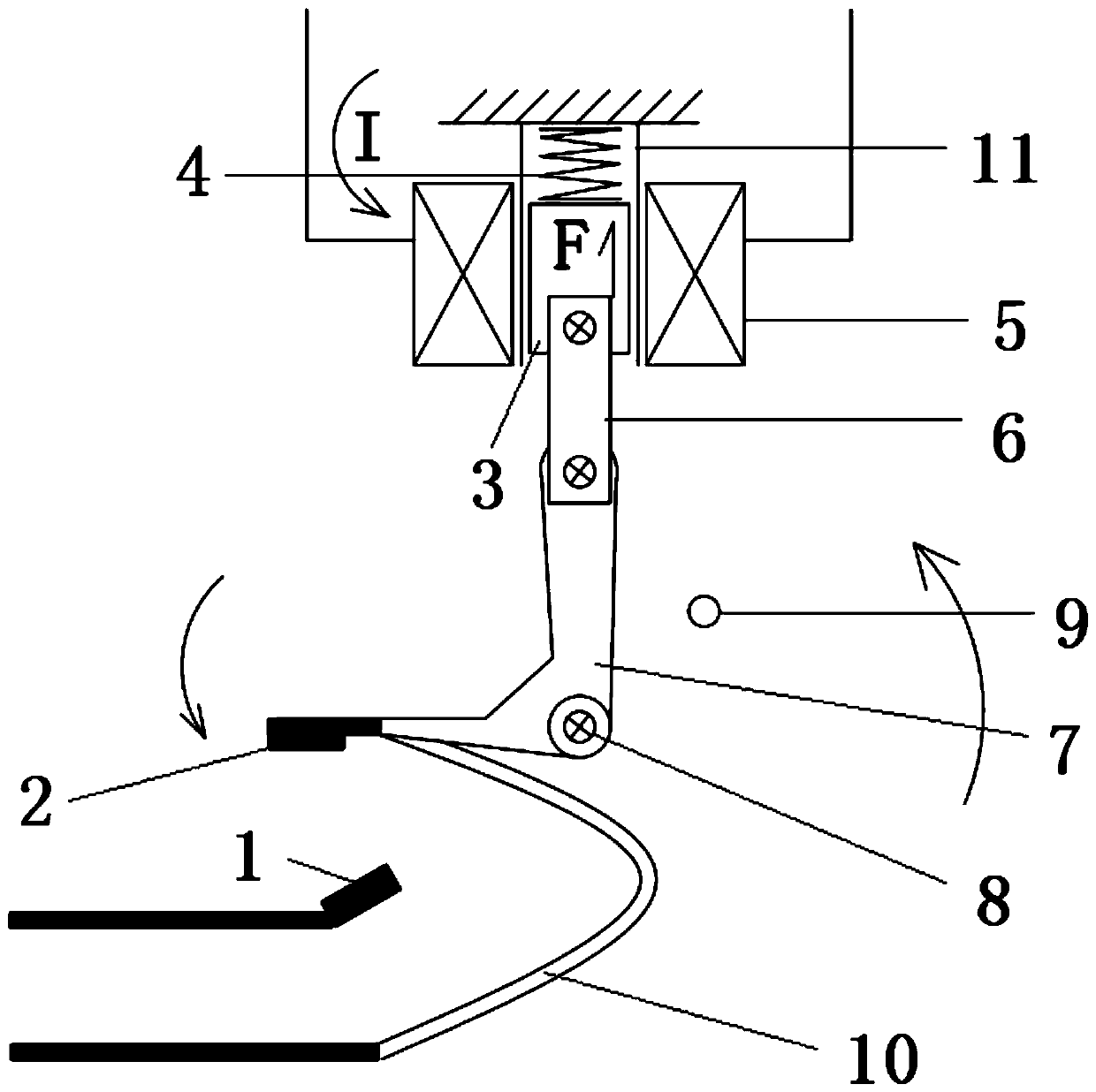

[0038] Such as figure 1 A specific implementation of the contactor shown in -3, including: iron core 3, electromagnetic coil 5 arranged on the outer periphery of iron core 3, swing structure 7 swinging along fixed axis 8, swinging direction along the swinging structure 7 The static contact 1 and the limit structure 9 are respectively arranged at the maximum swing range on both sides thereof.

[0039] The first end of the iron core 3 along its moving direction is provided with an elastic member 4, the elastic member 4 is in a compressed state, the other end of the elastic member 4 abuts against a fixed structure 11, and the second end of the iron core 3 The end is hinged with connecting rod 6. In this embodiment, when the electromagnetic coil 5 is energized, the iron core 3 overcomes the first elastic force of the elastic member 4 and moves in a direction away from the fixed shaft 8 under the action of the upward magnetic field force, that is, drives the connecting rod 6 to ve...

Embodiment 2

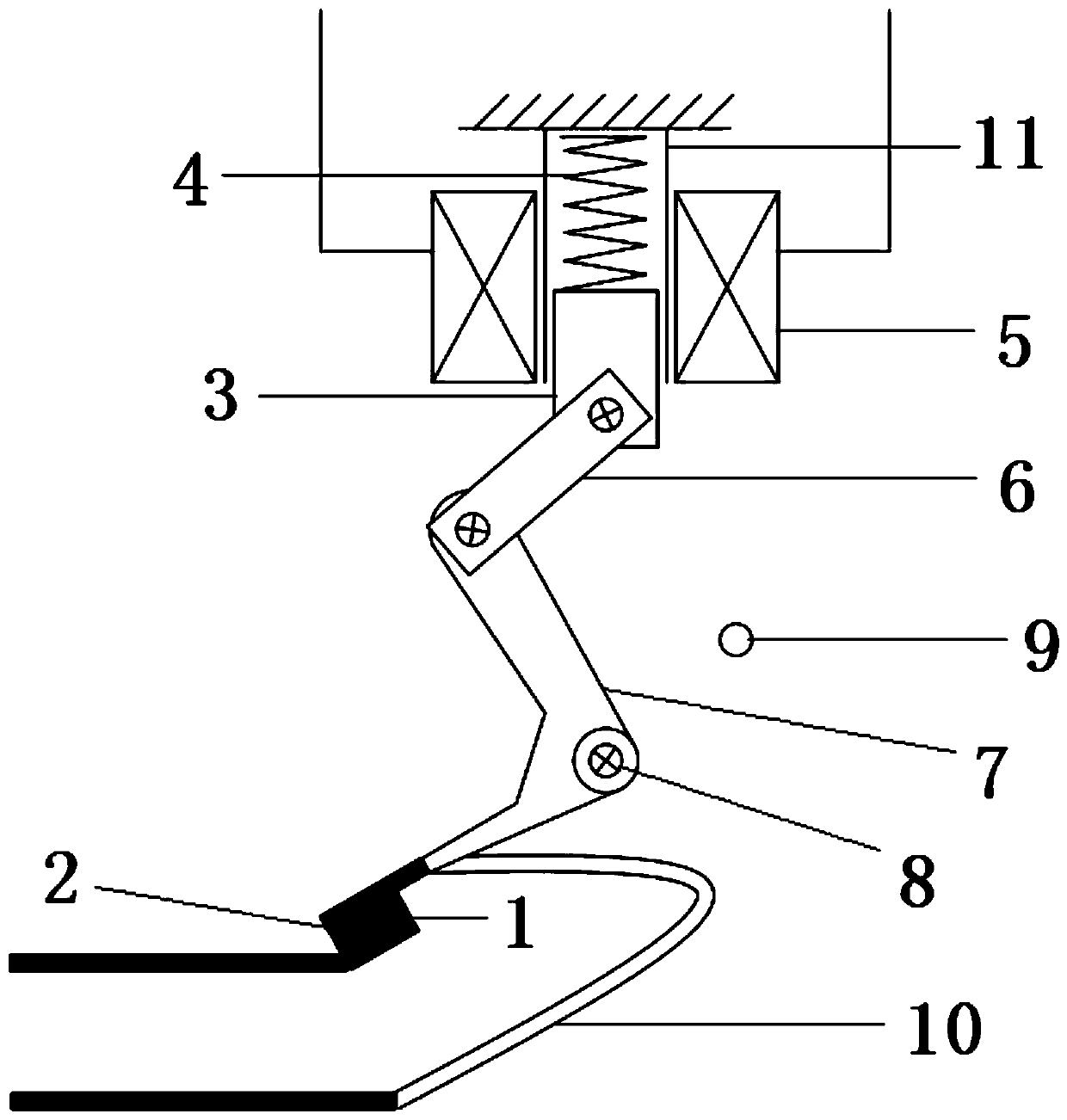

[0048] Such as Figure 4 As shown in -6, the swing structure 7 is a semicircular runner, the hinge point of the connecting rod 6 and the swing structure 7 is located on the axis of the semicircular runner, and the movable contact 2 is set At the intersection of the arc surface and the plane of the semicircular wheel. Other structures are the same as in Embodiment 1.

[0049] The rotation angle of the movable contact 2 is less than 90 degrees when it rotates. Such a design can increase the closing speed and breaking speed between the moving contact and the static contact.

Embodiment 3

[0051] The oscillating structure 7 is a circular wheel, and the movable contact 2 is extended from the arc surface of the circular wheel. The circular runner is also provided with a counterweight structure, and the counterweight structure and the circular runner form an eccentric wheel. Specifically, the counterweight structure is an arc-shaped structure arranged at the edge of the circular runner, and the connecting rod 6 is hingedly connected with the arc-shaped structure.

[0052] Further, a driving rod is arranged on the circular wheel, and the movable contact 2 is connected with the driving rod. The design of the driving rod can make the installation of the moving contact 2 more convenient. Other structures are the same as in Embodiment 1. Specifically, there is one driving rod, and the movable contact 2 is arranged on a side of the driving rod facing the static contact 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com